6 inch Welded Stainless Steel Pipe 316l handrails

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

C | Si | Mn | P | S | Ni | Cr | |

| SS304 | 0.046 | 0.316 | 1.481 | 0.0424 | 0.0028 | 8.001 | 18.019 |

| SS201 | 0.111 | 0.31 | 9.45 | 0.029 | 0.006 | 0.871 | 14.110 |

| SS316 | ≤0.08 | ≤1 | ≤2 | 0.035 | 0.03 | 1.0~14.0 | 16.0~18.5 |

Shape | Round / Square Etc. |

Brand | PEMCO/OEM/ODM |

Material | SS Stainless Steel 201, 304 , 316 |

Quality | First Grade |

Finish | Satin/Mirror |

Technology | Casting |

Certificate | ISO 9001-2000 |

Application | *Construction And Stair , Handrail , Railing Use |

*Shopping Mall,House,Outdoor | |

Feature | Beautiful Outlook, Easy To Clean, Low Maintenance Cost |

Usage | Widely Used On Stainless Steel Balustrade & Handrails, Indoor Or Outdoor Decorations,Etc. |

MOQ | 10 Pieces |

Delivery Time | 15-20 Days |

Colors for you to choose:

hot sale

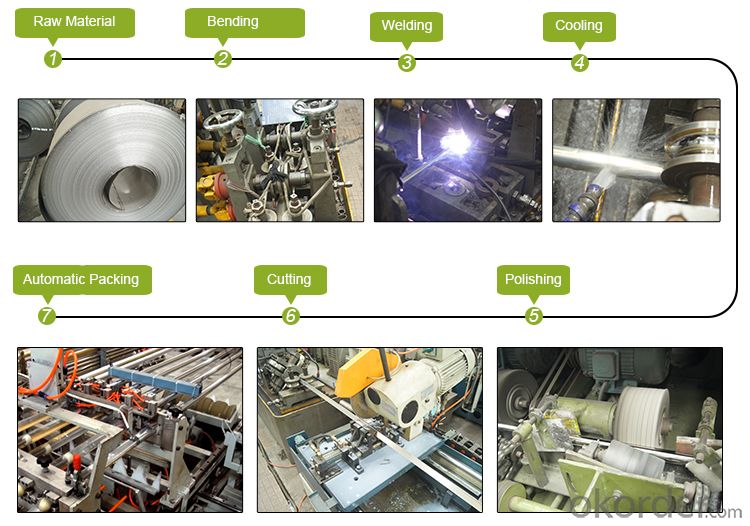

Production Process

Our Services

Pre-sale service:

1. Quotation: stainless steel pipe handrails price will be quoted according to material grade, size, thickness, length of each piece, finish and your quantity you want.

2. Sample: free samples can be sent for your reference.

3. OEM/ ODM Service: Your 2D/3D drawings or samples are welcome.

4. Other reasonable requests: factory photos, test reports, certifications, etc. to show.

Sale service:

1. Payment Method:

For samples, freight can be paid via Paypal, Westernunion or to our bank account.

Deposit and the balance can be paid via bank account or Alibaba Onetouch.

2. Business Term: EXW, FOB, CIF, etc.

3. Delivery: To door service - Internationl Express (DHL, FedEx, TNT, etc.)

Airport or shipping transportation

4. Payment and Shipping Terms:

Alibaba Onetouch Paypal Western Union Bank Transfer

- Q: What is the difference between bright annealed and annealed pickled stainless steel pipes?

- Bright annealed and annealed pickled stainless steel pipes differ in their surface finish and treatment processes. Bright annealed stainless steel pipes undergo a heat treatment known as annealing in a controlled atmosphere to eliminate internal stresses and improve the material's ductility. This process also results in a bright and shiny surface finish, making the pipes suitable for applications that require an aesthetically pleasing appearance, such as decorative or architectural purposes. On the other hand, annealed pickled stainless steel pipes undergo a two-step treatment process. First, the pipes are annealed to remove any stresses and improve their mechanical properties. Then, they undergo a pickling process where the surface is chemically treated to remove scale, oxides, and other impurities. This treatment leaves the pipes with a dull and rough surface finish, which is often desired for applications that require subsequent coatings, such as painting or galvanizing. In summary, the main difference between bright annealed and annealed pickled stainless steel pipes lies in their surface finish. Bright annealed pipes have a bright and shiny appearance, while annealed pickled pipes have a dull and rough surface finish due to the pickling process. The choice between the two types depends on the specific requirements of the intended application.

- Q: Can stainless steel pipes be used for wastewater treatment systems?

- Yes, stainless steel pipes can be used for wastewater treatment systems. Stainless steel is a highly durable and corrosion-resistant material, making it an ideal choice for pipes in harsh environments such as wastewater treatment plants. These pipes can withstand the corrosive nature of wastewater, including the presence of chemicals and different pH levels. Stainless steel pipes also have a smooth surface, which helps to minimize the accumulation of waste and bacteria, ensuring the efficient flow of wastewater through the system. Additionally, stainless steel is easy to clean and maintain, making it a cost-effective and reliable choice for wastewater treatment systems.

- Q: How thick is the 3 stainless steel tube?

- 3 thicknesses representing 3 mm wall thickness

- Q: Can stainless steel pipes be used for architectural purposes?

- Stainless steel pipes are indeed capable of being utilized for architectural purposes. The architectural applications of stainless steel are facilitated by several properties it possesses. Firstly, its resistance to corrosion is incredibly high, a crucial factor for structures that are exposed to the elements. Moreover, the sleek and modern appearance of stainless steel pipes can impart an aesthetic touch to architectural designs. In addition to this, stainless steel is a formidable and long-lasting material that provides structural integrity and longevity to buildings. Its versatility allows it to be incorporated into a variety of architectural elements, including handrails, balustrades, staircases, and structural supports. All in all, due to their combination of corrosion resistance, aesthetic appeal, and strength, stainless steel pipes are a widely favored choice for architectural purposes.

- Q: Can stainless steel pipes be recycled?

- Yes, stainless steel pipes can be recycled. Stainless steel is a highly recyclable material due to its durability and corrosion resistance. When stainless steel pipes reach the end of their useful life or are no longer needed, they can be collected, processed, and melted down to create new stainless steel products. Recycling stainless steel pipes not only helps conserve natural resources but also reduces energy consumption and emissions associated with mining and manufacturing new materials.

- Q: Can stainless steel pipes be bent or curved?

- Stainless steel pipes possess the ability to undergo bending or curving. This is due to the inherent versatility of stainless steel, which enables it to adopt diverse shapes, including bends and curves. The remarkable ductility and high tensile strength of stainless steel contribute to this flexibility. In numerous industries like construction, automotive, and manufacturing, stainless steel pipes are commonly shaped to meet specific design requirements. The desired shape and specifications determine the appropriate bending method, which can include hot bending, cold bending, or mandrel bending. It is crucial to emphasize that the bending or curving of stainless steel pipes necessitates the use of proper equipment and expertise. This ensures the preservation of the pipe's integrity and quality.

- Q: What are the temperature limitations of stainless steel pipes?

- The temperature limitations of stainless steel pipes typically depend on the grade of stainless steel being used. Generally, stainless steel pipes can withstand high temperatures, with some grades capable of operating at temperatures up to 1500°F (815°C). However, prolonged exposure to extremely high temperatures can cause stainless steel to lose its strength and corrosion resistance. It is important to consult the specific grade and manufacturer's recommendations to determine the temperature limitations for a particular stainless steel pipe.

- Q: Are stainless steel pipes suitable for drinking water applications?

- Yes, stainless steel pipes are suitable for drinking water applications. Stainless steel is a highly durable and corrosion-resistant material, making it an excellent choice for transporting drinking water. It does not leach harmful substances into the water and is resistant to rust and scaling, ensuring the water remains clean and safe for consumption. Additionally, stainless steel pipes are easy to clean and maintain, which further promotes the hygiene of the water supply. The long lifespan and reliability of stainless steel pipes also make them a cost-effective solution for drinking water applications.

- Q: Are stainless steel pipes suitable for fertilizer production?

- Yes, stainless steel pipes are suitable for fertilizer production. Stainless steel pipes offer a number of advantages that make them a preferred choice for use in the fertilizer industry. Firstly, stainless steel pipes are highly resistant to corrosion, which is particularly important in the production of fertilizers. Fertilizer production involves the use of chemicals and substances that can be highly corrosive, such as ammonia, sulfuric acid, and phosphoric acid. Stainless steel pipes can withstand the corrosive effects of these substances, ensuring the integrity and longevity of the piping system. Additionally, stainless steel pipes have excellent strength and durability, making them able to withstand the high pressures and temperatures often encountered in fertilizer production processes. This ensures the safe and efficient transportation of the fertilizer materials within the production plant. Furthermore, stainless steel pipes are hygienic and easy to clean, which is crucial for maintaining the purity of the fertilizer products. Stainless steel has a smooth surface that resists the buildup of bacteria, dirt, and other contaminants, ensuring that the pipes do not contaminate the fertilizer during production. Lastly, stainless steel is a sustainable and environmentally friendly material. It is 100% recyclable, making it a more sustainable choice compared to other pipe materials. Additionally, stainless steel has a long lifespan, reducing the need for frequent replacements and minimizing waste. In conclusion, stainless steel pipes are highly suitable for fertilizer production due to their corrosion resistance, strength, durability, hygienic properties, and environmental benefits.

- Q: Can stainless steel pipes be used for hydroelectric power plants?

- Hydroelectric power plants can indeed utilize stainless steel pipes. The reason stainless steel is favored for various industrial applications is because of its exceptional corrosion resistance. Within a hydroelectric power plant, the generation of electricity is achieved by the passage of water through turbines. The composition and flow rate of this water can often result in corrosive tendencies. Consequently, stainless steel pipes, which are highly resistant to corrosion, are the ideal conduit for conveying the water in hydroelectric power plants. Furthermore, stainless steel pipes bring forth additional advantages such as superior strength, durability, and the capacity to withstand elevated pressures and temperatures. These properties are vital for ensuring the efficient and dependable operation of the power plant. Moreover, stainless steel pipes maintain their structural integrity over time, thus reducing the need for frequent maintenance and replacement. In addition, stainless steel pipes possess the ability to handle the internal and external pressures that arise during the power generation process. They can effectively endure the high-speed flow of water and resist erosion caused by sediment and debris in the water supply. Consequently, the longevity and efficiency of the hydroelectric power plant are secured. To conclude, stainless steel pipes are an exceptional choice for hydroelectric power plants due to their corrosion resistance, strength, durability, and ability to withstand high pressures and temperatures.

Send your message to us

6 inch Welded Stainless Steel Pipe 316l handrails

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords