3in Stainless Steel Pipe

3in Stainless Steel Pipe Related Searches

3 Inch Stainless Steel Pipe 3 Stainless Steel Pipe 3 4 Stainless Steel Pipe 3/4 In Stainless Steel Pipe 3 4 Stainless Steel Tubing 4 Inch Stainless Steel Pipe 1 Inch Stainless Steel Pipe 2 Inch Stainless Steel Pipe Stainless Steel Threaded Pipe 4 Stainless Steel Pipe Stainless Steel Piping 3/8 In Stainless Steel Tubing Stainless Steel Pipes 304 Stainless Steel Pipe 1 Stainless Steel Pipe 6 Stainless Steel Pipe 3/4 Stainless Steel Tubing Stainless Steel Flue Pipe 2 Stainless Steel Pipe 3/8 Stainless Steel Tubing Stainless Steel Smoker Pipe Pipe Stainless Stainless Steel Screen Pipe 1 2 Stainless Steel Pipe 3d Printed Stainless Steel Stainless Steel 3d Printer Stainless Steel Chimney Pipe 3/16 Stainless Steel Stainless Steel Flex Pipe 1in Stainless Steel Tubing3in Stainless Steel Pipe Supplier & Manufacturer from China

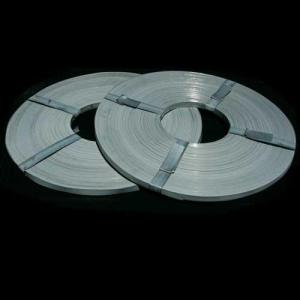

The 3in Stainless Steel Pipe is a type of pipe made from stainless steel, known for its durability and corrosion resistance. It is available in various sizes, with the 3-inch diameter being one of the most popular options. This pipe is widely recognized for its strength and ability to withstand harsh conditions, making it an ideal choice for numerous applications.The 3in Stainless Steel Pipe is commonly used in industries such as construction, oil and gas, and food processing due to its ability to maintain structural integrity and resist corrosion. It is particularly useful in environments where high levels of moisture or chemicals are present, as the stainless steel material prevents rust and other forms of degradation. This makes it a popular choice for applications such as water and gas pipelines, as well as in the manufacturing of industrial equipment and machinery.

Okorder.com is a leading wholesale supplier of the 3in Stainless Steel Pipe, offering a vast inventory to cater to the needs of various industries. With a commitment to providing high-quality products at competitive prices, Okorder.com ensures that customers have access to reliable and durable stainless steel pipes for their projects and operations.