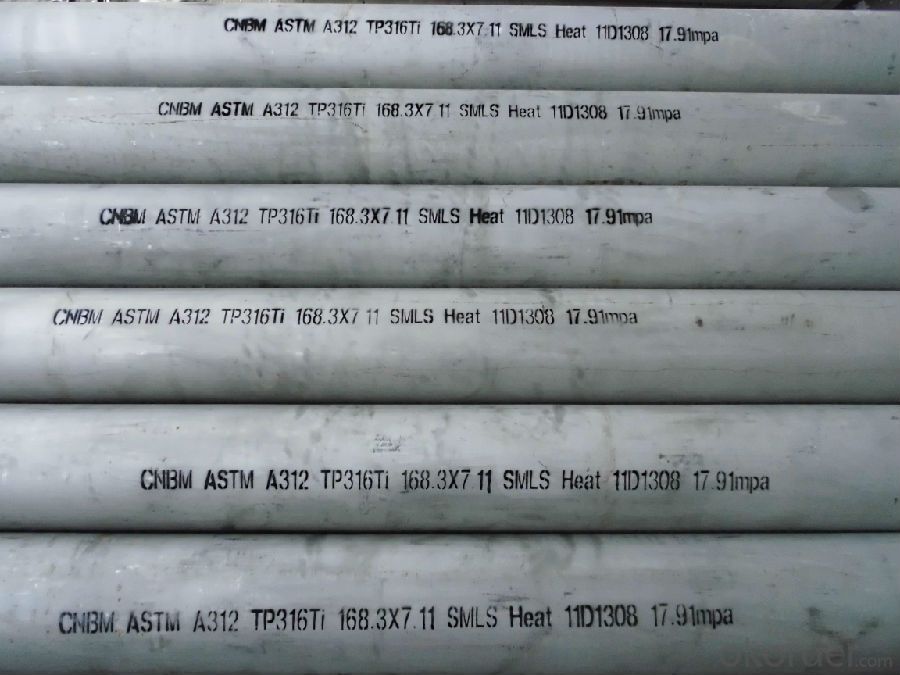

Stainless steel pipe 316Ti 3

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

316Ti stainless steel plate is the addition of Ti in SUS316 steel can improve the resistance to intergranular corrosion resistance.

The chemical composition of 316Ti stainless steel:

C (%): less than 0.08

Si (%): less than 1

Mn (%): less than 2

P (%) is less than or equal to: 0.045

S (%) is less than or equal to 0.03

Cr (%): 16 ~ 18

Ni (%): 10 ~ 14

Mo (%): 2 ~ 3

other (%):

5 (C+N) = Ti = 0.70, N = 0.10

The mechanical properties of 316Ti stainless steel:

YS (Mpa) = 205 TS (Mpa) = 520 EL (%) is more than or equal to 40 Hv 200 degrees

- Q: Can stainless steel pipes be used for automotive exhaust systems?

- Yes, stainless steel pipes can be used for automotive exhaust systems. Stainless steel is a popular choice for exhaust systems due to its excellent corrosion resistance, high temperature strength, and durability. It can withstand the extreme heat and harsh conditions that are common in automotive exhaust systems, making it a reliable and long-lasting option. Stainless steel pipes also have a smooth surface, which helps to reduce friction and improve exhaust flow, leading to improved performance and fuel efficiency. Additionally, stainless steel is a lightweight material, which can help to reduce the overall weight of the vehicle and improve its handling. Overall, stainless steel pipes are a suitable and commonly used material for automotive exhaust systems.

- Q: Are stainless steel pipes suitable for fire sprinkler systems?

- Yes, stainless steel pipes are suitable for fire sprinkler systems. They offer excellent corrosion resistance, durability, and strength, making them an ideal choice for such systems. Stainless steel pipes can withstand high temperatures and maintain their structural integrity, ensuring reliable performance in fire emergencies.

- Q: Can stainless steel pipes be used for steam systems?

- Yes, stainless steel pipes can be used for steam systems. Stainless steel is known for its excellent resistance to corrosion and high temperature, making it a suitable material for carrying steam. It can withstand the high pressure and temperature of steam without corroding or degrading, ensuring the efficiency and safety of the steam system. Additionally, stainless steel pipes have low thermal conductivity, which helps to minimize heat loss during steam transportation. Overall, stainless steel pipes offer durability, reliability, and longevity, making them a popular choice for steam systems in various industries.

- Q: How do stainless steel pipes compare to carbon steel pipes?

- Stainless steel pipes are generally more resistant to corrosion and rust than carbon steel pipes. They have higher strength and durability, making them suitable for various applications, including those requiring high pressure or extreme temperatures. While carbon steel pipes are typically more affordable, they are susceptible to corrosion and may require additional protective coatings. Ultimately, the choice between stainless steel and carbon steel pipes depends on the specific requirements and environment of the intended use.

- Q: Can stainless steel pipes be used for brewery applications?

- Yes, stainless steel pipes can be used for brewery applications. Stainless steel is highly resistant to corrosion and can withstand the harsh conditions of a brewery environment, such as exposure to moisture and chemicals. It is also easy to clean and maintain, making it a suitable choice for transporting liquids in a brewery setting.

- Q: Can stainless steel pipes be used for sewage and wastewater systems?

- Indeed, sewage and wastewater systems can make use of stainless steel pipes. Stainless steel is renowned for its exceptional resistance to corrosion, rendering it highly suitable for water and sewage-related purposes. Its ability to withstand rust, corrosion, and chemical reactions ensures an extended lifespan while reducing the necessity for frequent replacements. Moreover, stainless steel pipes possess a smooth surface that hinders the accumulation of debris and facilitates effortless cleaning. Furthermore, stainless steel is impermeable, preventing the growth of harmful bacteria and fungi, thus contributing to its hygienic nature and suitability for sewage and wastewater systems. The durability, dependability, and capacity to withstand harsh environmental conditions make stainless steel pipes a favored choice for such applications.

- Q: What is the difference between ferritic and austenitic stainless steel pipes?

- The primary distinction between ferritic and austenitic stainless steel pipes lies in their microstructure and composition, resulting in different properties and applications. Ferritic stainless steel pipes possess a ferrite microstructure, characterized by a body-centered cubic crystal structure. They boast high chromium levels (typically 10-30%) and low carbon content. This low carbon composition grants them excellent resistance against corrosion, though they are susceptible to sensitization and intergranular corrosion at elevated temperatures. Furthermore, they exhibit commendable durability, heat resistance, and magnetism, rendering them suitable for various uses such as automotive exhaust systems, architectural structures, and heat exchangers. In contrast, austenitic stainless steel pipes possess an austenite microstructure, characterized by a face-centered cubic crystal structure. These pipes contain high levels of chromium (usually 16-26%) and nickel (typically 6-22%), alongside low carbon content. Austenitic stainless steel pipes demonstrate superior resistance against corrosion, even in highly aggressive environments. They are non-magnetic, extremely ductile, and possess high toughness, making them ideal for industries such as chemical processing, food and beverage, pharmaceuticals, and medical equipment manufacturing. Additionally, they are less prone to sensitization and intergranular corrosion compared to their ferritic counterparts. To summarize, ferritic stainless steel pipes possess a ferrite microstructure, good corrosion resistance, and magnetism, while austenitic stainless steel pipes possess an austenite microstructure, superior corrosion resistance, non-magnetic properties, and enhanced mechanical properties. The choice between ferritic and austenitic stainless steel pipes hinges on the specific application, desired properties, and environmental conditions.

- Q: Are stainless steel pipes suitable for abrasive media?

- Yes, stainless steel pipes are suitable for abrasive media. Stainless steel is known for its high resistance to corrosion and wear, making it an excellent choice for handling abrasive materials. Its durability and strength ensure that it can withstand the erosive properties of abrasive media, making stainless steel pipes a reliable option for such applications.

- Q: How do you cut stainless steel pipes?

- Cutting stainless steel pipes can be done using several methods. Here are a few common techniques: 1. Using a hacksaw: This is a manual method of cutting stainless steel pipes. Make sure to choose a blade specifically designed for cutting metal. Secure the pipe in a vise or clamp to prevent it from moving while cutting. Mark a straight line where you want to cut and slowly and steadily saw through the pipe using back and forth motions. Apply consistent pressure to avoid damaging the pipe. 2. Using a reciprocating saw: A reciprocating saw with a metal cutting blade can also be used to cut stainless steel pipes. Clamp the pipe securely and mark the cutting line. Start the saw and slowly guide it along the marked line, applying steady pressure. This method is quicker than using a hacksaw and requires less manual effort. 3. Using a pipe cutter: A pipe cutter is a specialized tool designed to cut pipes cleanly and accurately. It consists of a sharp cutting wheel that is rotated around the pipe, gradually tightening it until the pipe is cut. This method is efficient and provides a smooth, burr-free cut. However, it may not be suitable for thicker or larger diameter stainless steel pipes. 4. Using a plasma cutter or a grinder: For thicker or larger diameter stainless steel pipes, a plasma cutter or a grinder equipped with a cutting wheel can be used. These power tools are capable of cutting through stainless steel quickly and efficiently. However, they require more expertise and safety precautions, so it is recommended to seek professional assistance if you are not familiar with these tools. Remember to wear appropriate safety gear, such as gloves and eye protection, when cutting stainless steel pipes. Additionally, always double-check the accuracy of your measurements and take necessary precautions to avoid injury.

- Q: How do you calculate the weight of stainless steel pipes?

- In order to determine the weight of stainless steel pipes, several factors should be taken into account. Firstly, one needs to establish the pipe's outer diameter (OD) and thickness (T). Once these measurements have been obtained, the weight per foot (or meter) of the stainless steel pipe can be calculated using the following formula: Weight per foot (or meter) = (OD - T) * T * 0.0246615 It should be noted that this formula assumes the stainless steel pipe is of a circular shape. By multiplying the weight per foot by the length of the pipe in feet (or meters), the total weight can be determined. It is important to acknowledge that the density of stainless steel may vary depending on the specific grade and composition. Therefore, the weight calculated using this formula will provide an approximate value. For precise weight calculations, it is advisable to consult a reference table or contact the manufacturer for more accurate information.

Send your message to us

Stainless steel pipe 316Ti 3

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords