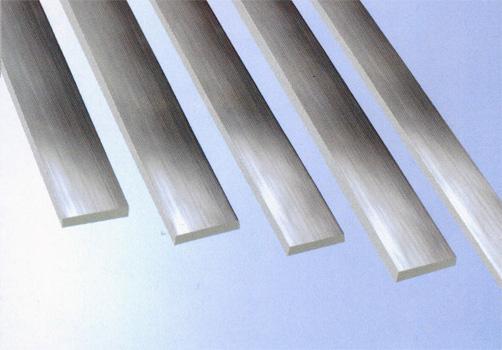

201 HL Stainless Steel Flats

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Flats

1. Standard: AISI, GB, JIS, ASTM, DIN, EN

2. Grade: 1).200Series: 201,202.

2).300Series: 301,302,303,304,304L,316,316L,321.

3).400Series: 410,410S,416,420,430,430F.

3. Size:3x25mm- 80x250mm

4. Length: 2m-6m

5. Craft: HRAP, or cold drawn

6. Stainless Steel Flat Bar Surface: Pickling or polished

7. MOQ: 1000kg

8. Delivery: within 20 days

9. Package: Waterproof with tape

10. Application: These products are widely supplied to areas of machine-made industry, chemical industry, shipping industry,architecture, food industry, household products etc.

|

Name |

Stainless Steel Flat Bar | ||||||||

|

Material |

201.202.301.304.304L,304N,304LN, 309S,310S,316,316L, 316Ti,316N,316LN,317,317L,347, 347H,etc. | ||||||||

|

Standard |

JIS/AISI/ ASTM,/GB,/DIN,/EN/SUS.etc. | ||||||||

Shape |

Stainless steel Round/flat/square/angle/hexagonal bar | ||||||||

Price term |

FOB/CIF/CNF or as required | ||||||||

|

Length |

6m,5.8m,4m as required | ||||||||

|

Application |

kitchen and sanitary wares , and Structural use high strength components,furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc | ||||||||

|

Payment terms |

L/C,T/T,Western Union,or as required. | ||||||||

|

MOQ |

As required | ||||||||

|

Packing |

Export standard package | ||||||||

|

Certificate |

ISO/SGS | ||||||||

|

Contact |

If you are interested in our products,please feel free to contact me. Cherryliu@okorder.com |

- Q: What are the maintenance requirements for stainless steel pipes?

- The maintenance requirements for stainless steel pipes are relatively low compared to other materials. However, there are a few key steps that should be taken to ensure their longevity and optimal performance. Firstly, regular cleaning is essential to remove any dirt, grime, or other contaminants that may accumulate on the surface of the pipes. This can be done using mild soap and water or a non-abrasive cleaner. It is important to avoid using abrasive materials or harsh chemicals as they can damage the stainless steel surface. Secondly, it is recommended to inspect the pipes periodically to check for any signs of corrosion or damage. Stainless steel is known for its resistance to corrosion, but in certain environments or under specific conditions, it can still be susceptible to corrosion. Any signs of corrosion should be addressed promptly to prevent further deterioration. Thirdly, stainless steel pipes should be protected from physical damage or impact. This can be achieved by avoiding heavy objects from hitting or rubbing against the pipes, as well as using appropriate padding or insulation in areas where they are exposed to potential impact. Lastly, it is important to ensure that stainless steel pipes are installed and used in accordance with their intended purpose and within their specified temperature and pressure limits. This will help prevent any undue stress or strain on the pipes, which could lead to premature failure. Overall, by following these maintenance requirements, stainless steel pipes can provide long-lasting durability and performance in a wide range of applications.

- Q: Are stainless steel pipes resistant to corrosion?

- Yes, stainless steel pipes are highly resistant to corrosion. This is due to the presence of chromium in stainless steel, which forms a passive layer on the surface of the pipe. This passive layer acts as a protective barrier, preventing the metal underneath from coming into contact with corrosive substances. The chromium content in stainless steel is typically at least 10.5%, which is higher than other types of steel, and this helps to enhance its corrosion resistance. Stainless steel pipes are widely used in various industries such as construction, oil and gas, and automotive, where corrosion resistance is essential to ensure the longevity and integrity of the pipes.

- Q: What is the average lead time for manufacturing stainless steel pipes?

- The average lead time for manufacturing stainless steel pipes can vary depending on several factors such as the complexity of the design, quantity required, and the manufacturer's production capacity. However, on average, it can range from a few weeks to a couple of months.

- Q: Can stainless steel pipes be used for gas or oil transportation?

- Yes, stainless steel pipes can be used for gas or oil transportation. Stainless steel pipes are known for their excellent corrosion resistance properties, making them a suitable choice for transporting corrosive fluids such as gas or oil. They are resistant to rust, oxidation, and other forms of corrosion, which ensures the integrity and longevity of the pipes. Additionally, stainless steel pipes have high strength and durability, making them capable of withstanding high-pressure applications commonly associated with gas or oil transportation. The smooth inner surface of stainless steel pipes also offers low frictional resistance, enabling efficient flow of fluids. However, it is important to consider factors such as the grade of stainless steel, compatibility with the specific gas or oil being transported, and compliance with relevant industry standards and regulations while selecting stainless steel pipes for gas or oil transportation.

- Q: How do you join stainless steel pipes together?

- To join stainless steel pipes together, there are several methods available, depending on the specific requirements and application. 1. Welding: Welding is the most common and widely used method for joining stainless steel pipes. It involves the application of heat to melt the material, forming a strong and durable bond. Different welding techniques like TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding can be used for this purpose. 2. Compression fittings: Compression fittings are a popular choice for joining stainless steel pipes, especially in plumbing applications. These fittings consist of a compression nut and a ferrule that are tightened onto the pipe, creating a secure and leak-proof connection. 3. Flanges: Flanges are used when a more robust connection is required, such as in high-pressure or high-temperature applications. Two stainless steel pipes are joined together by bolting flanges at the ends, creating a tight and reliable connection. 4. Threaded connections: Stainless steel pipes can also be joined using threaded connections, where one end of the pipe is threaded and the other end is fitted with a threaded pipe fitting, such as a union or nipple. This method is commonly used for smaller diameter pipes or in situations where disassembly may be required. 5. Clamps and couplings: Clamps and couplings are used to join stainless steel pipes temporarily or in situations where frequent disassembly is required. These devices clamp around the pipes and are tightened using bolts or other mechanisms, creating a secure connection. It is important to consider the specific requirements, such as pressure, temperature, and corrosion resistance, when choosing the appropriate method to join stainless steel pipes. Consulting with a professional or referring to industry standards and guidelines can ensure a successful and reliable pipe connection.

- Q: The difference between stainless steel pipe and stainless steel composite pipe

- Stainless steel composite pipe is made of stainless steel and carbon steel two kinds of metal materials with new materials nondestructive pressure synchronization into the compound, both stainless steel corrosion and excellent wear and beautiful appearance, good bending strength and impact resistance of carbon steel.

- Q: How do stainless steel pipes compare to fiberglass pipes?

- Stainless steel pipes and fiberglass pipes have distinct characteristics and advantages that set them apart. When comparing stainless steel pipes to fiberglass pipes, several factors should be considered, including strength, durability, corrosion resistance, cost, and ease of installation. In terms of strength, stainless steel pipes have a clear advantage. They are known for their exceptional strength and durability, making them ideal for withstanding high-pressure applications and heavy loads. On the other hand, fiberglass pipes are relatively weaker and may not be suitable for applications that require high strength and resistance. Durability is another crucial aspect to consider. Stainless steel pipes are highly durable and can withstand extreme temperatures, chemicals, and physical stress without deteriorating. Fiberglass pipes, although durable, are more susceptible to damage from impact, extreme temperatures, and UV radiation. This makes stainless steel pipes a more reliable choice for long-term use in harsh environments. Corrosion resistance is a significant factor in pipe selection. Stainless steel pipes are renowned for their excellent corrosion resistance, making them ideal for applications where exposure to corrosive substances is a concern. Fiberglass pipes, while relatively resistant to many chemicals, can be affected by certain corrosive substances and may require additional protective coatings. Cost is an important consideration for any project. Stainless steel pipes tend to be more expensive than fiberglass pipes due to the higher cost of raw materials and manufacturing processes. Fiberglass pipes, on the other hand, are generally more affordable, making them a cost-effective option for projects with budget constraints. Finally, ease of installation is worth mentioning. Stainless steel pipes require specialized tools and expertise for installation due to their weight and rigidity. Fiberglass pipes, being lightweight and flexible, are easier to handle and install, reducing labor costs and time. In conclusion, stainless steel pipes offer superior strength, durability, and corrosion resistance compared to fiberglass pipes. However, fiberglass pipes are a more cost-effective option and easier to install. The choice between the two ultimately depends on the specific requirements of the project, considering factors such as the application, budget, and environmental conditions.

- Q: Are stainless steel pipes suitable for underground installations?

- Indeed, underground installations can accommodate stainless steel pipes with ease. Renowned for its durability and strength, stainless steel boasts exceptional resistance against corrosion. It effectively endures the harshest underground conditions, enduring moisture, soil movement, and exposure to chemicals. Furthermore, stainless steel pipes remain impervious to rust, eliminating the need for protective coatings and establishing them as optimal for prolonged underground utilization. Moreover, their extensive lifespan and minimal maintenance requirements further solidify their appropriateness for underground installations.

- Q: What is the external coating used for stainless steel pipes?

- The external coating used for stainless steel pipes can vary, but common options include epoxy, polyethylene, or polypropylene coatings.

- Q: What is the internal roughness of stainless steel pipes?

- The internal roughness of stainless steel pipes refers to the texture or unevenness on the inner surface of the pipes, which can affect the flow of fluids or gases through the pipes. It is typically measured in terms of roughness coefficients or Ra values, indicating the average height of irregularities on the pipe's interior.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2010 |

| Annual Output Value | above US$3 million |

| Main Markets | East Asia, Middle East. |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 50% |

| No.of Employees in Trade Department | above 10 people |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | about 50000 square meter |

| No. of Production Lines | above 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

201 HL Stainless Steel Flats

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords