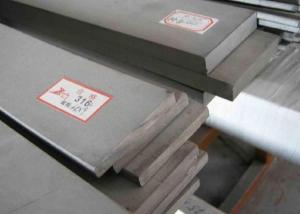

Stainless Steel 316L Flats and Pipes

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

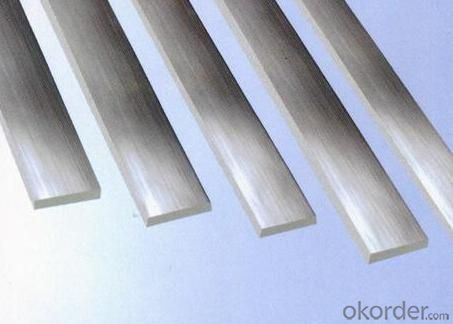

Stainless Steel Flats

1. Standard: AISI, GB, JIS, ASTM, DIN, EN

2. Grade: 1).200Series: 201,202.

2).300Series: 301,302,303,304,304L,316,316L,321.

3).400Series: 410,410S,416,420,430,430F.

3. Size:3x25mm- 80x250mm

4. Length: 2m-6m

5. Craft: HRAP, or cold drawn

6. Stainless Steel Flat Bar Surface: Pickling or polished

7. MOQ: 1000kg

8. Delivery: within 20 days

9. Package: Waterproof with tape

10. Application: These products are widely supplied to areas of machine-made industry, chemical industry, shipping industry,architecture, food industry, household products etc.

|

Name |

Stainless Steel Flat Bar | ||||||||

|

Material |

201.202.301.304.304L,304N,304LN, 309S,310S,316,316L, 316Ti,316N,316LN,317,317L,347, 347H,etc. | ||||||||

|

Standard |

JIS/AISI/ ASTM,/GB,/DIN,/EN/SUS.etc. | ||||||||

Shape |

Stainless steel Round/flat/square/angle/hexagonal bar | ||||||||

Price term |

FOB/CIF/CNF or as required | ||||||||

|

Length |

6m,5.8m,4m as required | ||||||||

|

Application |

kitchen and sanitary wares , and Structural use high strength components,furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc | ||||||||

|

Payment terms |

L/C,T/T,Western Union,or as required. | ||||||||

|

MOQ |

As required | ||||||||

|

Packing |

Export standard package | ||||||||

|

Certificate |

ISO/SGS | ||||||||

|

Contact |

If you are interested in our products,please feel free to contact me. Cherryliu@okorder.com |

- Q:Can stainless steel pipes be used for oil and gas refineries?

- Indeed, oil and gas refineries can utilize stainless steel pipes. Given its exceptional durability and resistance to corrosion, stainless steel proves to be an appropriate choice for the challenging and corrosive conditions typically encountered in refineries. It can endure substantial pressures, extreme temperatures, and the presence of diverse chemicals and corrosive elements frequently encountered in oil and gas operations. Moreover, stainless steel pipes provide outstanding protection against erosion, pitting, and cracking, guaranteeing the long-lasting integrity of the pipeline system.

- Q:How do you insulate stainless steel pipes?

- To prevent heat loss, condensation, and energy wastage, insulating stainless steel pipes is a crucial step. There are multiple effective methods available for insulating these pipes: 1. Pipe insulation wraps: The most common and cost-effective method involves using wraps made of materials like fiberglass, rubber, or foam. These wraps are easy to install and provide excellent insulation against heat transfer. They also serve as a barrier to prevent condensation. 2. Insulation jackets: Pre-formed covers made of insulation materials such as mineral wool or fiberglass are used for this method. These jackets are designed to fit around the stainless steel pipes and are secured with adhesive or straps. They offer a high level of thermal insulation and are ideal for pipes in areas with extreme temperatures. 3. Spray foam insulation: This method entails spraying a layer of polyurethane foam insulation directly onto the stainless steel pipes. This creates a seamless and durable insulation layer that adheres well to the pipes, providing excellent thermal insulation and preventing moisture buildup. 4. Insulation tape: Foam or rubber insulation tape is wrapped around the stainless steel pipes to provide thermal insulation. This method works best for smaller pipes or areas with limited space. Regardless of the chosen method, it is important to consider the temperature range, moisture exposure, and specific requirements of the stainless steel pipes when selecting insulation materials. Additionally, proper installation and maintenance of the insulation are essential to optimize its effectiveness and durability.

- Q:Are stainless steel pipes suitable for oil refineries?

- Yes, stainless steel pipes are suitable for use in oil refineries. Stainless steel is highly corrosion resistant, which is essential in an environment with high levels of corrosive substances such as crude oil and various chemicals used in refining processes. Stainless steel pipes are capable of withstanding high temperatures and pressures, making them ideal for transporting oil and gas within the refinery. Additionally, stainless steel pipes have low maintenance requirements and a long lifespan, reducing the need for frequent replacements and minimizing downtime. Overall, stainless steel pipes provide the durability, reliability, and resistance to corrosion necessary for the demanding conditions of oil refineries.

- Q:Can stainless steel pipes be used for steam piping?

- Yes, stainless steel pipes can be used for steam piping. Stainless steel is known for its high resistance to corrosion, making it an excellent choice for steam applications. Steam piping requires materials that can withstand high temperatures and pressure, and stainless steel is capable of meeting these requirements. Additionally, stainless steel pipes have good thermal conductivity, ensuring efficient transfer of heat in steam systems. However, it is important to consider the specific grade of stainless steel and its suitability for steam applications, as some grades may be more appropriate than others depending on the conditions and requirements of the system.

- Q:Can stainless steel pipes be used in high-pressure applications?

- Yes, stainless steel pipes can be used in high-pressure applications. Stainless steel is known for its excellent corrosion resistance, durability, and strength, making it an ideal material for handling high-pressure fluids or gases. The high-pressure resistance of stainless steel pipes is due to their high tensile strength and ability to withstand extreme conditions without deformation or failure. Additionally, stainless steel pipes can maintain their properties at both high and low temperatures, ensuring their reliability and performance in high-pressure applications.

- Q:What is the difference between 304J1 and 316J1 stainless steel pipes?

- The main difference between 304J1 and 316J1 stainless steel pipes lies in their chemical composition and the presence of certain elements. 304J1 stainless steel is a variant of the popular 304 stainless steel grade. It has a lower carbon content compared to regular 304, which makes it more resistant to intergranular corrosion. This is achieved by adding a small amount of titanium to the composition. 304J1 stainless steel pipes are suitable for general-purpose applications, such as plumbing, food processing, and architectural uses. On the other hand, 316J1 stainless steel is a variant of the 316 stainless steel grade. It is similar to regular 316 stainless steel in terms of corrosion resistance but has a lower carbon content, similar to 304J1. Additionally, 316J1 contains a small amount of molybdenum, which enhances its resistance to pitting and crevice corrosion in chloride environments. As a result, 316J1 stainless steel pipes are commonly used in marine environments, chemical processing plants, and other applications where exposure to corrosive substances is expected. In summary, the primary difference between 304J1 and 316J1 stainless steel pipes is in their chemical composition, with the latter offering superior resistance to corrosion in more aggressive environments. The choice between the two would depend on the specific application and the level of corrosion resistance required.

- Q:What are the different types of stainless steel pipe flanges?

- There are several different types of stainless steel pipe flanges, including slip-on flanges, weld neck flanges, socket weld flanges, threaded flanges, blind flanges, and lap joint flanges. Each type has its own unique design and application, making them suitable for various piping systems and industries.

- Q:In stainless steel tubes, why are there some SS in the back and some standard L, such as 316L and 316SS? What's the difference?

- 316: corresponding to China's brand 0Cr17Ni12Mo2316L: corresponding to Chinese brand 00Cr17Ni14Mo2316L steel is a low C series of 316 steel grades. It has better corrosion resistance except for the same characteristics as 316 steel.

- Q:What is the difference between Type 304L and Type 316L stainless steel pipes?

- Type 304L and Type 316L stainless steel pipes are both popular choices for various applications due to their corrosion-resistant properties. However, they differ in their composition and performance in specific environments. The main difference lies in their alloy content. Type 304L stainless steel contains 18-20% chromium and 8-12% nickel, while Type 316L stainless steel contains 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. The addition of molybdenum in Type 316L enhances its resistance to corrosion, particularly in chloride-rich environments. This makes Type 316L more suitable for applications where the pipes will be exposed to seawater, brine, or other aggressive chemicals. Another distinguishing factor is their mechanical properties. Type 316L stainless steel has slightly higher tensile strength and yield strength compared to Type 304L. It also exhibits better creep and stress rupture properties, making it more suitable for high-temperature applications. However, Type 304L is still a good choice for most general-purpose applications and offers excellent durability and longevity. In terms of cost, Type 316L stainless steel pipes are generally more expensive than Type 304L due to the added alloying elements. Therefore, the choice between the two will depend on the specific requirements of the application, considering factors such as the corrosive environment, temperature, and budget. Overall, while both Type 304L and Type 316L stainless steel pipes offer excellent corrosion resistance, Type 316L provides superior performance in more aggressive environments and higher temperatures. It is important to consult with a materials expert or engineer to determine the most suitable stainless steel pipe for a specific application.

- Q:Can stainless steel pipes be used for pulp and paper mills?

- Yes, stainless steel pipes can be used for pulp and paper mills. Stainless steel offers excellent corrosion resistance, high strength, and durability, making it an ideal choice for piping systems in harsh environments like pulp and paper mills. The acidic and corrosive nature of the chemicals used in the paper-making process can lead to the deterioration of conventional pipes, but stainless steel pipes can withstand these conditions without compromising their structural integrity. Additionally, stainless steel pipes are easy to clean and maintain, which is crucial in industries where hygiene is of utmost importance. Therefore, stainless steel pipes are a reliable and long-lasting solution for the piping needs of pulp and paper mills.

1. Manufacturer Overview |

|

|---|---|

| Location | Jiangsu, China |

| Year Established | 2010 |

| Annual Output Value | above US$3 million |

| Main Markets | East Asia, Middle East. |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 50% |

| No.of Employees in Trade Department | above 10 people |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | about 50000 square meter |

| No. of Production Lines | above 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Stainless Steel 316L Flats and Pipes

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords