Stainless Steel Sheets Decorative 201 Colored Black Stainless Steel Sheet in Good Price

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications for Stainless Steel Coils/Sheets:

Grade | C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Ni ≤ | Cr ≤ |

201 | 0.12 | 0.75 | 7.00 | 0.045 | 0.045 | 1.00-1.28 | 13.70-15.70 |

202 | 0.15 | 1.00 | 2.25 | 0.045 | 0.045 | 4.07-4.17 | 14.00-16.00 |

304 | 0.08 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-11.00 | 18.00-20.00 |

304L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-13.00 | 18.00-20.00 |

309 | 0.15 | 0.75 | 2.00 | 0.045 | 0.03 | 12.00-15.00 | 22.00-24.00 |

310S | 0.08 | 1.50 | 2.00 | 0.045 | 0.03 | 19.00-22.00 | 24.00-26.00 |

316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

316L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 10.00-15.00 | 16.00-18.00 |

321 | 0.04-0.10 | 0.75 | 2.00 | 0.045 | 0.03 | 9.00-13.00 | 17.00-20.00 |

405 | 0.08 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

409 | 0.089 | 1.00 | 1.00 | 0.045 | 0.05 | 0.06 | 10.50-11.75 |

410 | 0.15 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

420 | 0.16-0.25 | 1.00 | 1.00 | 0.040 | 0.03 | 0.06 | 12.00-14.00 |

430 | 0.12 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 16.00-18.00 |

Type | 200 series,300 series,400 series |

Thickness | 1.8-8.0mm |

Widthness | 1000/1219/1500mm |

Technique | Hot Rolled/Cold Rolled |

Coil Weight | About 20 Tons |

Finish | NO.1/NO.2B |

Place of Origin | Made in China |

MOQ | 18 ton |

Color | Black,Mirror Finished |

Standard | ASTM, JIS, GB, BS, DIN etc |

Exporting countries | Peru,India,Pakistan,Singpore,Vietnam,South Korea,Malaysia etc. |

After-sales service | Factory Inspection |

Certifications | ISO,SGS |

Packaging | Standard export packing or following customer's demand |

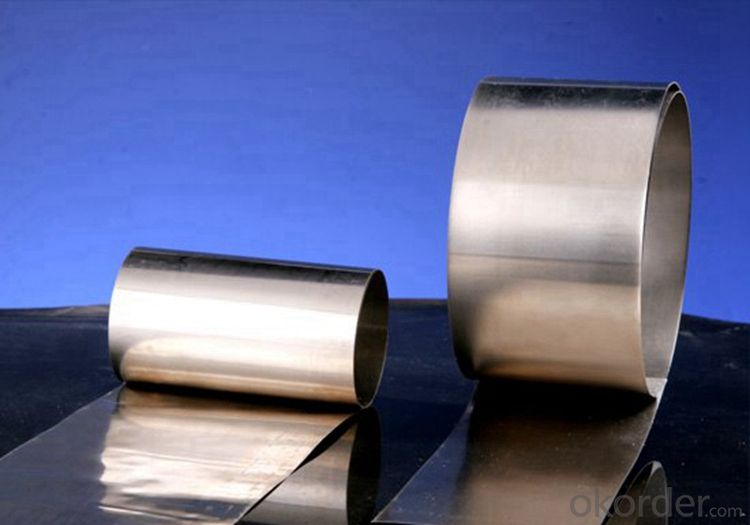

Detail picture for Stainless Steel Coils/Sheets

Application for Stainless Steel Coils/Sheets:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail | Standard export packing or following customer's demand |

Delivery Time | Within 30-40 days after deposit or according to the order quantity |

Application for Stainless Steel Coils/Sheets

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

- Q: Do stainless steel sheets have a warranty?

- Yes, stainless steel sheets typically come with a warranty. The length and terms of the warranty may vary depending on the manufacturer or supplier. It is recommended to check with the specific company or review the product documentation for information on the warranty coverage.

- Q: What are the benefits of using etched stainless steel sheets in signage?

- There are several benefits of using etched stainless steel sheets in signage. Firstly, etched stainless steel sheets are extremely durable and long-lasting. Stainless steel is known for its resistance to corrosion, rust, and fading, making it ideal for outdoor signage that is exposed to harsh weather conditions. Secondly, etched stainless steel sheets offer a sleek and professional appearance. The process of etching allows for intricate designs, logos, and text to be permanently engraved onto the surface of the stainless steel. This creates a high-end and visually appealing finish that adds a touch of sophistication to any signage. Furthermore, etched stainless steel sheets are highly customizable. They can be tailored to meet specific design requirements, making them suitable for a wide range of signage applications. Whether it is for architectural signage, company logos, directional signs, or wayfinding systems, etched stainless steel sheets can be designed to suit any style or branding. Moreover, stainless steel is easy to clean and maintain. It can be wiped down with a cloth or cleaned with mild soap and water, ensuring that the signage remains in pristine condition for an extended period. This low maintenance requirement is particularly advantageous for outdoor signage, where regular cleaning may be necessary. Lastly, etched stainless steel sheets offer excellent visibility. The engraved designs on the stainless steel surface can be filled with paint or other materials to create contrast, making the signage highly visible even from a distance or in low light conditions. This enhanced visibility is crucial for effective signage, as it ensures that the intended message or information is easily communicated to the target audience. In conclusion, the benefits of using etched stainless steel sheets in signage include durability, a professional appearance, customization options, easy maintenance, and excellent visibility. These advantages make etched stainless steel sheets a popular choice for signage applications in various industries.

- Q: What does stainless steel sheet S2 stand for?

- Stainless steel sheet S2 stands for thickness 2mm

- Q: What are the common types of corrosion that affect stainless steel sheets?

- The common types of corrosion that affect stainless steel sheets include pitting corrosion, crevice corrosion, stress corrosion cracking, and galvanic corrosion.

- Q: What is the difference between stainless steel sheets and stainless steel plates?

- In various industries, stainless steel sheets and stainless steel plates find common use and possess similar properties. However, they differ in terms of thickness and application. Typically, stainless steel sheets exhibit a thinner profile compared to stainless steel plates. These sheets are usually less than 6mm thick and serve decorative purposes, such as in kitchen appliances, automotive trim, and signage. Moreover, they showcase excellent malleability, allowing easy bending and shaping for projects that demand flexibility. In contrast, stainless steel plates boast greater thickness and resilience compared to sheets. These plates usually exceed 6mm in thickness and find extensive application in heavy-duty scenarios like construction, machinery, and industrial equipment. Their increased strength, durability, and corrosion resistance make them ideal for withstanding high temperatures, pressure, and mechanical stress. Moreover, the manufacturing process presents another point of departure. Stainless steel sheets typically undergo cold rolling or hot rolling, resulting in a smooth and flat surface. On the other hand, stainless steel plates are often produced through hot rolling followed by heat treatment, which enhances their mechanical properties. To summarize, while both stainless steel sheets and stainless steel plates share the same material composition, their differing thickness, application, and manufacturing process distinguish them. Sheets exhibit a thinner and more flexible nature, primarily catering to decorative purposes. Plates, in contrast, possess greater thickness, strength, and durability, catering to heavy-duty applications that necessitate robustness.

- Q: Can stainless steel sheets be painted?

- Yes, stainless steel sheets can be painted. However, it is important to properly prepare the surface before painting to ensure good adhesion and longevity of the paint. The stainless steel surface should be cleaned and degreased thoroughly, and any existing rust or oxidation should be removed. A primer specifically formulated for use on metal surfaces should be applied to promote adhesion, followed by a high-quality paint designed for metal. It is also recommended to apply a clear coat or sealer to protect the paint finish. Keep in mind that regular maintenance may be required to maintain the appearance of the painted stainless steel sheets, as the paint may chip or wear over time.

- Q: Can stainless steel sheets be used for storage racks?

- Yes, stainless steel sheets can be used for storage racks. Stainless steel is a durable and corrosion-resistant material, making it suitable for storing various items. It also has a high load-bearing capacity, making it ideal for heavy-duty storage applications.

- Q: What is the maximum thickness available for stainless steel sheets?

- The maximum thickness available for stainless steel sheets can vary depending on the specific grade of stainless steel and the manufacturing capabilities of the supplier. However, in general, stainless steel sheets can be found in thicknesses ranging from 0.5mm to 80mm. It is important to note that thicker sheets are typically used for specialized applications that require increased strength and durability, such as construction projects or heavy machinery. When selecting stainless steel sheets, it is crucial to consider the intended use and consult with a reputable supplier to ensure that the desired thickness is available.

- Q: What is the process of stainless steel mirror panel? What's the difference between them and stainless steel sand blasting plates?

- Stainless steel sand blasting plates are painted on stainless steel sand blasting plates. Stainless steel sand blasting plate refers to the use of zirconium beads through the mechanical equipment in the stainless steel plate processing, so that the surface of the board presents small beads, grainy sand surface, forming a unique decorative effect. Stainless steel sand blasting decorative board uses: mainly used in architectural decoration, elevator decoration, industrial decoration, facilities decoration and other stainless steel products.

- Q: Are stainless steel sheets resistant to high-pressure environments?

- Stainless steel sheets exhibit remarkable resistance to high-pressure environments. This material boasts robustness and durability, enabling it to endure the immense force exerted by diverse industrial operations, including hydraulic systems, chemical processing plants, and oil and gas pipelines. Its outstanding tensile strength and capacity to maintain structural integrity even in the face of extreme pressure make it highly esteemed. Moreover, stainless steel also possesses corrosion resistance, further bolstering its suitability for high-pressure settings where exposure to moisture or chemicals is prevalent. Consequently, stainless steel sheets are extensively employed in industries that demand materials capable of withstanding high-pressure circumstances due to their exceptional strength and resistance attributes.

Send your message to us

Stainless Steel Sheets Decorative 201 Colored Black Stainless Steel Sheet in Good Price

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords