Prime Quality Stainless Steel 201 Grade Stainless Steel Sheets For Construction Building Metals

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

Cold Rolled Size: Thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

MOQ: 20 Tons

Payment Terms: 100% LC at sight, or 100%TT in advance

Delivery Time: With 30-40 days after deposit

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

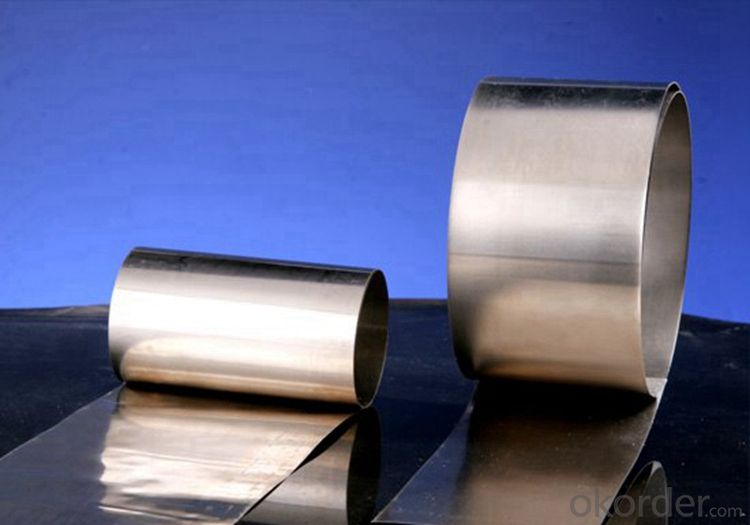

Detail picture for Stainless Steel Coils/Sheets

Application for Stainless Steel Coils/Sheets:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

Application for Stainless Steel Coils/Sheets

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

- Q: Can stainless steel sheets be used for medical equipment?

- Indeed, medical equipment can utilize stainless steel sheets. The medical industry extensively employs stainless steel due to its remarkable resistance to corrosion, its durability, and its ease of cleaning. Surgical instruments, implants, medical devices, and equipment like sterilization trays, hospital beds, and operating room tables are commonly manufactured using stainless steel. As it does not react with bodily tissues or fluids, stainless steel is a secure and sanitary option for medical purposes. Moreover, it can endure numerous sterilization procedures without compromising its qualities, thus rendering it perfectly suited for hospitals and healthcare facilities.

- Q: Can stainless steel sheets be used in food processing or medical applications?

- Stainless steel sheets have the capability to be utilized in food processing and medical applications. The reason behind its popularity in these industries is its outstanding resistance to corrosion, high durability, and effortless cleaning properties. The material is able to withstand chemical reactions, ensuring safety when it comes into contact with food and medical equipment. Commonly employed in food processing equipment, storage tanks, countertops, and surgical instruments, stainless steel sheets conform to the strict hygiene standards mandated in the food and medical sectors, thus establishing themselves as a dependable and fitting material for these applications.

- Q: Are stainless steel sheets suitable for storage tanks?

- Yes, stainless steel sheets are suitable for storage tanks. Stainless steel is a highly durable and corrosion-resistant material, making it an ideal choice for storing various substances. It offers excellent resistance to rust and corrosion, ensuring that the tank remains intact and free from leaks. Stainless steel also has a high strength-to-weight ratio, allowing for the construction of large storage tanks without sacrificing structural integrity. Additionally, stainless steel is easy to clean and maintain, making it a hygienic choice for storing food-grade or pharmaceutical substances. Overall, stainless steel sheets are a reliable and long-lasting option for storage tanks in various industries.

- Q: Are stainless steel sheets suitable for chemical storage tanks?

- Yes, stainless steel sheets are highly suitable for chemical storage tanks. Stainless steel is corrosion-resistant, durable, and can withstand high temperatures and pressures. It provides excellent resistance against a wide range of chemicals, making it ideal for storing various types of chemicals safely and securely.

- Q: What is the thickness tolerance for stainless steel sheets?

- The thickness tolerance for stainless steel sheets can vary depending on the specific grade and manufacturing process. Generally, the industry standard thickness tolerance for stainless steel sheets ranges from +/- 0.005 inches to +/- 0.010 inches. However, it is important to note that different manufacturers and suppliers may have their own specific tolerances, so it is always advisable to refer to the specifications provided by the manufacturer or supplier for accurate information. Additionally, certain applications or industries may have more stringent thickness tolerances, and in such cases, it is crucial to adhere to the specific requirements outlined by the customer or industry standards.

- Q: How do you join stainless steel sheets together?

- There are various methods to join stainless steel sheets together, depending on the specific application and desired outcome. Here are a few common techniques: 1. Welding: Stainless steel can be welded using various methods such as TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), or spot welding. Welding creates a strong and durable bond between the sheets, ensuring a secure connection. 2. Mechanical Fasteners: Using mechanical fasteners like screws, bolts, or rivets can be an effective way to join stainless steel sheets. This method is often used when disassembly or reassembly is required, as it allows for easy removal and reinstallation. 3. Adhesive Bonding: Specialized adhesives designed for stainless steel can be used to join sheets together. These adhesives create a strong bond while maintaining the aesthetics of the stainless steel surface. However, adhesive bonding may not be suitable for high-stress or high-temperature applications. 4. Clinching: Clinching involves using a special tool to press the stainless steel sheets together, creating a mechanical interlock. This method is commonly used for joining thin sheets and offers a cost-effective and fast solution. It is important to choose the appropriate method based on the specific requirements of the project, including factors such as load-bearing capacity, temperature, corrosion resistance, and aesthetics. Consulting with a professional or conducting thorough research can help ensure the chosen joining technique is suitable for the intended application.

- Q: How are stainless steel sheets made?

- Stainless steel sheets undergo a process called hot rolling to be produced. This starts by melting iron, nickel, chromium, and other elements in an electric arc furnace. The resulting mixture is then cast into large rectangular blocks known as slabs. The slabs are subjected to high temperatures and passed through a series of hot rolling mills. These mills consist of large rollers that gradually decrease the slab's thickness while increasing its length and width. As the slab goes through each rolling mill, it is constantly squeezed by the rollers, resulting in a thinner and longer sheet. Following the hot rolling process, the stainless steel sheet goes through annealing. This involves heating the sheet to a specific temperature and then allowing it to cool slowly. This process helps release internal stresses and enhance the material's mechanical properties. Next comes pickling, where the sheet is submerged in an acid solution to eliminate any surface impurities and oxides. This improves the appearance and corrosion resistance of the stainless steel. Once the pickling process is done, the sheet undergoes cold rolling. Cold rolling further decreases the sheet's thickness and improves its surface finish. This is done at room temperature, increasing the hardness and strength of the stainless steel. Lastly, the stainless steel sheet undergoes various finishing processes. These may include cutting to size, leveling, surface polishing, and coating to enhance appearance or protect against corrosion. In conclusion, the manufacturing process of stainless steel sheets involves a combination of melting, casting, hot rolling, annealing, pickling, cold rolling, and finishing processes. This ensures that the final product meets the desired specifications in terms of thickness, strength, and surface finish.

- Q: Are stainless steel sheets suitable for architectural handrails or guardrails?

- Yes, stainless steel sheets are highly suitable for architectural handrails or guardrails. Stainless steel is known for its durability, corrosion resistance, and aesthetic appeal, making it an ideal material for such applications. Its strength and long-lasting properties ensure the handrails or guardrails can withstand heavy usage and harsh weather conditions while maintaining a sleek and modern appearance.

- Q: What is the maximum width available for stainless steel sheets?

- The maximum width available for stainless steel sheets can vary depending on the manufacturer and supplier. However, in general, stainless steel sheets are commonly available in widths ranging from 36 inches (0.91 meters) to 72 inches (1.83 meters). Some manufacturers may offer even wider options for specialized applications. It is always advisable to check with the specific supplier or manufacturer for the maximum width available, as it may vary based on their production capabilities and product offerings.

- Q: How do I determine the flatness of stainless steel sheets?

- To determine the flatness of stainless steel sheets, you can follow these steps: 1. Visual Inspection: Start by visually inspecting the sheet for any visible signs of warping, bending, or unevenness. Look for any noticeable waves, ripples, or twists in the surface. While this method may not be the most accurate, it can give you an initial idea of the sheet's overall flatness. 2. Measuring with a Straight Edge: Place a straight edge, such as a ruler or a long level, on the surface of the stainless steel sheet. Move the straight edge across different areas of the sheet, focusing on both the center and the edges. Observe if there are any gaps or spaces between the straight edge and the sheet. If the straight edge remains in full contact with the sheet throughout, it indicates a good level of flatness. 3. Using a Feeler Gauge: A feeler gauge is a precision measurement tool consisting of a set of thin metal blades of varying thicknesses. It can be used to measure the gap between the straight edge and the stainless steel sheet more accurately. Slide the feeler gauge into any gaps between the sheet and the straight edge, noting the blade thickness that fits snugly. This will help determine the extent of any unevenness or bowing present. 4. Laser Measurement: For more precise measurements, you can use a laser measuring device. Place the laser device on one end of the sheet and measure the distance from the laser to the surface at various points along the length of the sheet. Repeat this process on the opposite end of the sheet. Comparing these measurements will give you an indication of any differences in flatness. 5. Professional Testing: If the stainless steel sheets are intended for critical applications or if precise flatness is crucial, it may be wise to consult with a professional testing service. They can utilize advanced techniques such as optical profilometry or coordinate measuring machines to accurately measure the flatness of the sheet. It is important to note that due to the inherent characteristics of stainless steel, some slight deviations from perfect flatness may be acceptable within industry standards. The level of flatness required will depend on the specific application and the tolerance standards set by the manufacturer or customer.

Send your message to us

Prime Quality Stainless Steel 201 Grade Stainless Steel Sheets For Construction Building Metals

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords