Stainless Steel Black

Stainless Steel Black Related Searches

Black Stainless Steel Samsung Black Stainless Steel Black Stainless Steel Chain Black Stainless Steel Kitchen Blacken Stainless Steel Blackened Stainless Steel Black Stainless Steel Paint Black Stainless Steel Range Black Stainless Steel Sheet Painting Stainless Steel Black Blackening Stainless Steel Stainless Steel Blackener Black Stainless Steel Toaster Stainless Steel Stainless Dark Stainless Steel Stainless Steel Blackstone Stainless Steel Metals Metal Stainless Steel Black Stainless Steel Gas Range Color Stainless Steel Stainless Steel Hardware Stainless Steel S Stainless Steel Tank White Stainless Steel Stainless Steel Lock Black Stainless Steel Trash Can Stainless Steel Thermo Stainless Steel Strap Stainless Steel Brakes Material Stainless SteelStainless Steel Black Supplier & Manufacturer from China

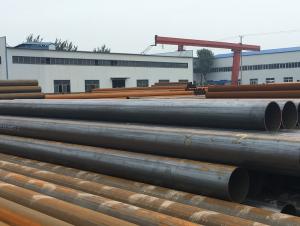

Stainless Steel Black, a popular choice among various industries, encompasses a range of products such as sheets, pipes, bars, and fasteners. These products are known for their durability, corrosion resistance, and sleek appearance, making them ideal for both functional and aesthetic purposes. The application and usage scenarios of Stainless Steel Black are diverse, spanning from construction and automotive to kitchen appliances and medical equipment. Its versatility allows it to be used in environments where strength, hygiene, and a modern look are paramount. As a wholesale supplier, Okorder.com offers a vast inventory of Stainless Steel Black products, catering to the needs of businesses and individuals alike. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Stainless Steel Black products they provide meet the highest industry standards.Hot Products