Stainless Steel Security Screen

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 SQM m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Security Screen

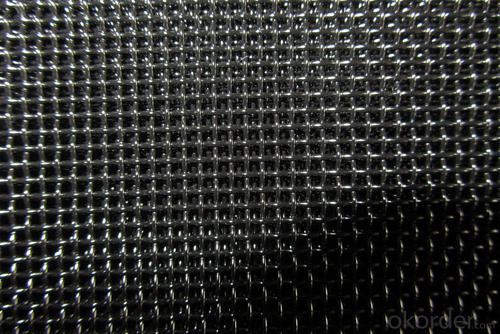

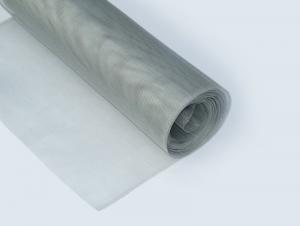

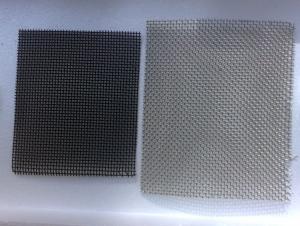

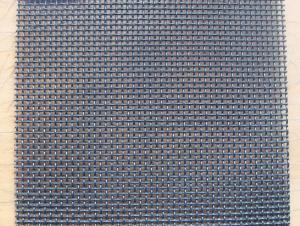

1) SUS316 (marine grade) 0.0315 inch (0.8 mm) wire diameter, high tensile stainlesssteel 10.5 strands per linear inch weft and 11 strands per linear inchwarp. The woven wire cloth according to ISO9044 / ASTM E2016-06standards. The open area space for the mesh is 42.7% (with min. tensilestrength > 800 lbs./linear inch).

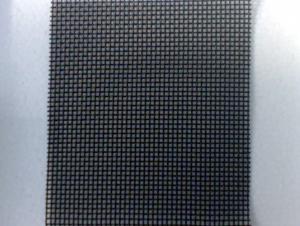

2) Themesh is powder coated to Australian Standard (AS4506-2005 Metal Finishing forthermo set powder coating). These standards set out relevant testprocedures and specify performance requirements for thermo-set powder coatingsapplied to metal substrates. Major applications specify for a stainlesssteel substrate with very high grade of industrial classification.

3) Thepre-treatment system incorporates process for the mesh which include alkalinecleaning, water rinsing, acid cleaning, water rinsing, deionizer, chromate,drying, and coating.

4) Independentsalt-spray testing has exceeded 10,000 hours under laboratory conditionsaccording to ASTM B117-2009.

5) ExtraSecurity Mesh Specification:

10Meshx0.9mm

10Meshx1.2mm

10Meshx0.8mm

12 Meshx0.58mm

12Meshx0.7mm

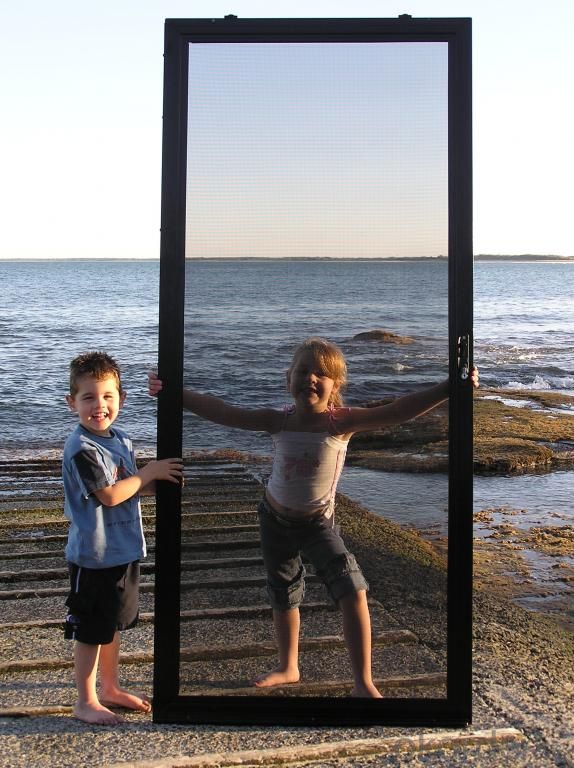

6)Standard Size:

3 ft x 4 ft

8 ft x 4 ft

4 ft x 4 ft

6 ft x 4 ft

3 ft x 3 ft

1 ft 4 " x 3 ft

Standard

All Security Series Stainless Steel Mesh Security Screens& Doors are manufactured and installed to comply with the strictrequirements of the following Australian Standards - Stainless Steel Mesh KnifeShear Test AS4483.2, Dynamic Impact Test AS4483.1, Lock and Hinge Lever TestAS5039 as well as Cyclone Rating AS1170.2

Security Screen Performance

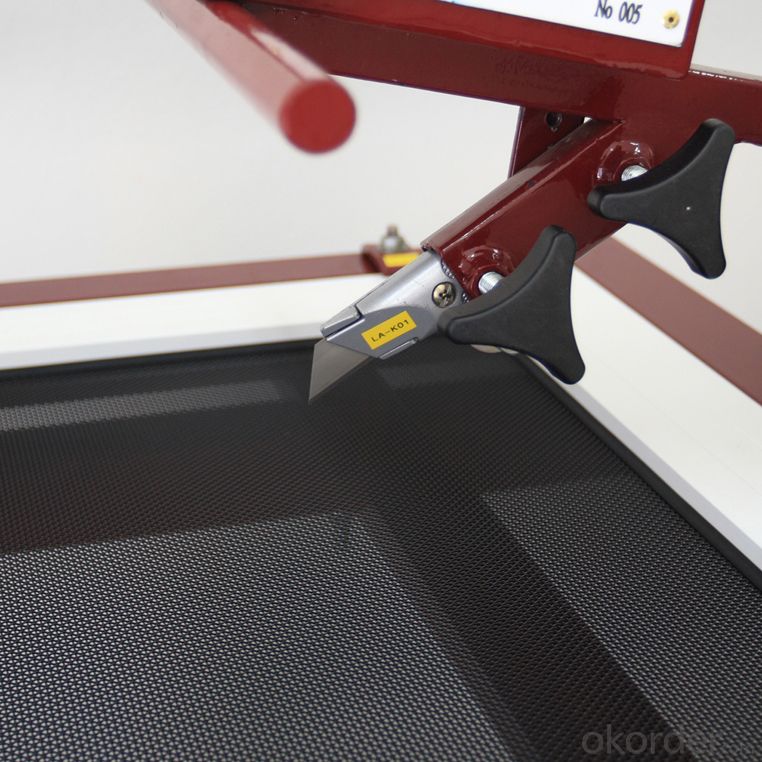

KnifeShear Test AS5039, AS5041

Standardizedcompliance test for security doors and windows. A specifically selected knifeis used to simulate an attack on the mesh, repeated 3 times, in a constantdirectional force.

Vertical force 15kg (150N); horizontal force 35 kg(150N); at avelocity of 6 mm/second.

DynamicImpact Test AS5039, AS5041

Another standardized compliance test appliedto ensure impact resistance to the fixing systemof a sash and panel components. The test comprisesof a heavy bag (36-46 kg) swung to directly impact the mesh, repeated fivetimes, in varying directions. Majestec security meshsuccessfully passes and/or exceeds this test.

Jemmy Test AS5039,AS5041

A strength test designed to simulate attemptedforced-entry by burglars and intruders using an implement to pry open doors andwindows or break locks and hinges by applying leverage forces against thelocking, fastening and hinging points.

SaltSpray Test ASTM B117

Corrosionresistance test for all metallic components. An accelerated climatemachine (10,000 hours equivalency to 10 years) produces acorrosive attack on coated samples, accuratelymeasuring the suitability and resistance of the protective finish to corrosiveagents. Simulates exposure to coastal weather conditions. Majestecsecurity mesh successfully passes and/or exceeds this test.

- Q: This is the inside of the inventor map, I want to draw the entity, the line is round.

- Or directly cut a piece of board, array into a network, a bit rough.You can draw a wavy line first

- Q: Who explained to me the use of metal mesh with the attention?

- When installed to follow the direction of the preparation of the network installation, the network with positive

- Q: I put the data line opened, want to extend the data line charging at the bedside, data line there is a layer of metal mesh, the thick black line is connected with the data line and the data line, I use ordinary enameled wire extension, only extended red and black, can be a normal charge, but the layer of metal mesh is used for what? For the field? I extend the data line feasible? Long-term use will not be on the screen of the mobile phone battery or what impact, please explain the ropes,

- In short, the anti interference, but also more solid. Generally do not have any effect, if you are in the vicinity of a strong magnetic field may be a bit of use, the general data line is the transmission of electrical signals, their ability to resist interference is relatively strong, unlike television antennas, such as. Oh, I understand. You're curious

- Q: I want to die stamping copper metal net recently, the old mouth jumped CR12

- You can increase the thickness of the wall or because you have a knife edge can be left hanging knife cut into the insert or insert into a small alloy can take the alloy knife to cut

- Q: Metal mesh GF2W0.63/0.20 what does it mean?

- The standard name is "industrial wire woven square hole screen"

- Q: Metal mesh structure can shield radiation

- Radiation everywhere, no matter you do not use a mobile phone, China Unicom mobile tower will emit radiation signal to you. The radio will send you radio signals. The next door neighbor wiffi will send you a wiffi signal.

- Q: What are the differences in the use of woven mesh, plain weave and twill weave?For example: from the aspect of stress, the strength of the twill than the plain to be large, etc.Plain woven nets are expensive and are more likely to be filtered or protected in the primary use, while the twill ones are notPlease answer the detailed points, thank you!

- Plain weave is used in screen iron screen window, no stretch

- Q: Urgent need for wire mesh inspection standards and aging box and salt spray test machine is used for what? Are there any technical requirements

- The main purpose of the thermal aging test of plastic electrical insulation and other materials is to test your product at a high temperature for a certain period of time

- Q: Is there a certain relationship between the diameter and the number?At this time the tension is probably how much?

- I've answered another questionGive a simple way to calculate their own

- Q: Headphones are metal mesh sound good?

- Icon9.gif this is really hard to say, you see, ah, there are not a few nails inside the metal mesh surface in addition to the sound of heavy dye (people have become their own characteristics)

Send your message to us

Stainless Steel Security Screen

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 SQM m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords