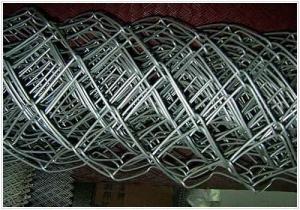

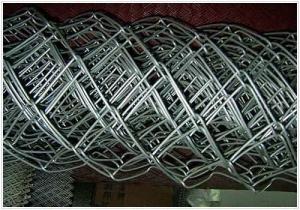

Stainless Steel Fence

Stainless Steel Fence Related Searches

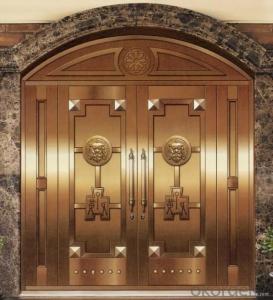

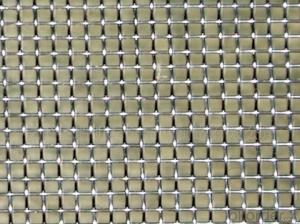

Stainless Steel Wire Fence Stainless Steel Fencing Stainless Steel Gate Stainless Steel Flange Galvanized Steel Fence Cast Iron Fence Stainless Steel Wall Stainless Steel Door Stainless Steel Fan Stainless Steel Siding Stainless Steel Front Door Stainless Steel Roof Stainless Steel Pipe Flange Stainless Steel Screen Stainless Steel Frame Stainless Steel Roofing Stainless Steel Signage Stainless Steel Curb Chain Stainless Steel Stand Stainless Steel Doors Stainless Steel Tank Stainless Steel Rope Chain Stainless Steel Enclosure Stainless Steel Drain Stainless Steel Bench Stainless Steel Staircase Stainless Steel Strap Stainless Steel Fountain Stainless Steel Cone Stainless Steel GunStainless Steel Fence Supplier & Manufacturer from China

Stainless Steel Fence is a durable and visually appealing option for various security and boundary needs. Made from high-quality stainless steel, these fences are designed to withstand harsh weather conditions and provide long-lasting protection. The sleek and modern design of stainless steel fencing makes it an ideal choice for both residential and commercial properties, offering a blend of aesthetics and functionality.Stainless Steel Fence is widely used in a variety of settings, such as gardens, parks, swimming pools, and industrial areas, where it serves as a reliable barrier against unauthorized access. Its corrosion-resistant properties make it suitable for coastal regions and areas with high humidity levels. Additionally, stainless steel fencing is low-maintenance, requiring minimal cleaning and upkeep, which makes it a popular choice among homeowners and businesses alike.

Okorder.com is a leading wholesale supplier of Stainless Steel Fence, boasting a vast inventory that caters to the diverse needs of customers worldwide. With a commitment to quality and customer satisfaction, Okorder.com ensures that each Stainless Steel Fence product meets the highest industry standards. By offering competitive prices and efficient shipping options, Okorder.com has established itself as a reliable source for purchasing Stainless Steel Fence for various applications.

Hot Products