Stainless Steel Decoration Chain link Fence for Garden

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

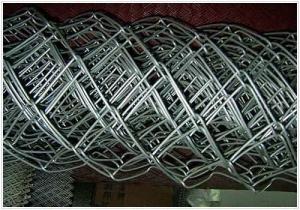

Product Description Stainless Steel Decoration Chain link Fence for Garden:

The perforate metal wind and dustproof wall can keep the clean cenvironment and save the coal for you.nd and dust screen, wind and dust barrier, windproof and dustproof wall, dust suppressiondproof wall

Specification of Stainless Steel Decoration Chain link Fence for Garden

Material: steel plate, galvanized plate, color coated sheet, stainless steel sheet.

Surface treatment: electrostatic powder coating.

Color: red ,blue or as customers' request.

Hole type: round, length, square, scale hole, hexagonal hole, plum blossom and so on.

Anti wind net application Stainless Steel Decoration Chain link Fence for Garden:

1. Power plants, coal mines, coking plants, coal washing plant, and other businesses field for coal saving

2. Ports, wharf and other coal storage yard

3. Open-air storage yard of the steel company, building materials company, cement companies, etc

4. All kinds of coal storage field

5. Temporary dustproof and windproof wall for the building site.

features of Stainless Steel Decoration Chain link Fence for Garden:

1. Can be readily formed

2. Easy installation

3. Can be painted or polished and anodizing

4. The thickness of materials is wide range from 0.3mm-8mm

5. Largest selection of hole size patterns and configurations

6. Uniform sound abatement

7. Attractive appearance

FAQ

1. Payment term: T/T, L/C, Western Union

2. Payment terms: 30% by T/T should be paid in advance, the balance payment paid againest the copy of B/L

3. Delivery time: shipping products within ten days, or negotiate according to total quantity.

4. Min order quantity: 50 pieces, or by negotiate with each other

- Q: Can steel wire mesh be used as a safety barrier?

- Yes, steel wire mesh can be used as a safety barrier. Steel wire mesh is a versatile material that can provide effective protection in various applications. It is commonly used as a safety barrier in construction sites, industrial areas, and public spaces. The strength and durability of steel wire mesh make it an ideal choice for containing and preventing access to hazardous areas. It can effectively prevent unauthorized entry, control traffic, and protect people and property from potential dangers. Additionally, steel wire mesh is resistant to corrosion and can withstand harsh weather conditions, ensuring long-lasting performance as a safety barrier. Overall, steel wire mesh is a reliable and cost-effective solution for creating a secure and safe environment.

- Q: Is steel wire mesh resistant to vandalism?

- Steel wire mesh can be considered resistant to vandalism due to its strong and durable nature. It is commonly used in various applications where security and protection are essential, such as fences, enclosures, and barriers. The robust construction of steel wire mesh makes it difficult for vandals to break or damage it easily. Additionally, the small openings in the mesh design prevent unauthorized access or tampering with the protected area. However, it is important to note that no material is completely immune to vandalism. Determined individuals with the right tools and sufficient time may still be able to cause some damage to steel wire mesh. Therefore, while it offers a high level of resistance, it is always advisable to take additional security measures when vandalism is a concern.

- Q: How does steel wire mesh perform in terms of resistance to saltwater?

- In terms of saltwater resistance, steel wire mesh generally performs admirably. Steel itself is an incredibly durable and corrosion-resistant material, making it suitable for a variety of applications, even those involving exposure to saltwater. Typically, the mesh is manufactured using stainless steel, which further enhances its ability to resist corrosion and rust. Saltwater contains high levels of chloride ions, which can accelerate the corrosion process in certain metals. However, stainless steel boasts a significant chromium content, which creates a protective oxide layer on the surface of the wire mesh. This oxide layer acts as a barrier, effectively preventing chloride ions from reaching the underlying steel and greatly reducing the risk of corrosion. Moreover, the construction of steel wire mesh, with its interconnected and interwoven strands, offers additional protection against corrosion. Even if the oxide layer is compromised in some areas, the mesh's structure ensures that corrosion remains localized and does not spread extensively. Steel wire mesh is commonly utilized in marine environments, such as seawater intake screens, fish cages, and coastal infrastructure. Its resistance to saltwater makes it a dependable choice for these applications, as it can endure prolonged exposure to the harsh conditions of saltwater without significant deterioration. However, it is crucial to note that no material is entirely immune to corrosion in saltwater. Over time, even stainless steel wire mesh may experience some level of corrosion or surface discoloration. Regular maintenance, including cleaning and the application of protective coatings, can help extend the lifespan and performance of steel wire mesh in saltwater environments.

- Q: How is steel wire mesh used in the automotive recycling industry?

- Steel wire mesh is commonly used in the automotive recycling industry for various purposes such as separating different materials, reinforcing structures, and protecting valuable components during the recycling process. It is commonly utilized as a screening material to separate different sizes of shredded materials, ensuring efficient sorting and recovery of recyclable metals. Additionally, steel wire mesh is often used to reinforce concrete structures in automotive recycling facilities, providing enhanced strength and durability. Moreover, it is also utilized as protective barriers or covers to shield valuable components or prevent debris from causing damage during the recycling process.

- Q: Is steel wire mesh suitable for use in window screens?

- Yes, steel wire mesh is suitable for use in window screens. Steel wire mesh is known for its durability and strength, making it an excellent choice for window screens. It is able to withstand harsh weather conditions, resist corrosion, and provide a high level of security. Additionally, steel wire mesh offers good visibility and allows for proper airflow while keeping insects and other pests out. Its sturdiness and longevity make it a reliable option for window screens, ensuring the protection and comfort of a home or building.

- Q: Can steel wire mesh be used for sorting and screening purposes?

- Steel wire mesh is an excellent option for sorting and screening applications. It is a versatile material widely used in various industries. Its strength, durability, and high tensile strength make it suitable for heavy-duty sorting and screening tasks. With steel wire mesh, different materials can be effectively separated and sorted based on their size, shape, or weight. It is capable of filtering and screening solid materials, liquids, and gases, making it perfect for industries like mining, construction, agriculture, and manufacturing. The availability of different mesh sizes ensures precise sorting and screening, allowing only desired materials to pass through while retaining unwanted particles. In conclusion, steel wire mesh is a reliable and efficient choice for sorting and screening due to its robust construction and ability to withstand harsh conditions.

- Q: Can steel wire mesh be used for architectural partitions?

- Yes, steel wire mesh can be used for architectural partitions. It offers a versatile and contemporary design solution, allowing for transparency and light penetration while providing structural integrity and security.

- Q: Can steel wire mesh be used for concrete formwork?

- Certainly, concrete formwork can utilize steel wire mesh. Steel wire mesh is a frequently employed material for reinforcing concrete structures, contributing to enhanced durability and stability. As formwork, the steel wire mesh serves as a framework or support system for the concrete throughout the pouring and curing stages. It effectively maintains the concrete in position and averts any sagging or collapse. Moreover, the steel wire mesh aids in distributing the load and bolstering the structural integrity of the concrete formwork. It is crucial to securely and accurately position the steel wire mesh to comply with the specified requirements and standards of the particular concrete project.

- Q: Can steel wire mesh be used for creating decorative wall panels?

- Certainly, decorative wall panels can indeed be created using steel wire mesh. The utilization of steel wire mesh brings about a one-of-a-kind and contemporary aesthetic that enhances the overall appearance and ambiance of any given space. It presents a robust and enduring solution for the formation of decorative wall panels, rendering it appropriate for both indoor and outdoor applications. The adaptability of steel wire mesh permits a multitude of design possibilities, encompassing diverse patterns, shapes, and sizes, thereby granting designers and homeowners the liberty to fashion personalized and visually captivating wall panels. Furthermore, steel wire mesh can be effortlessly manipulated and molded to suit various architectural designs, thus establishing it as a versatile material for the construction of decorative wall panels. All in all, steel wire mesh is a superb option for individuals seeking to infuse their walls with a contemporary and tasteful essence.

- Q: Is steel wire mesh suitable for use in oil and gas industry applications?

- Yes, steel wire mesh is suitable for use in oil and gas industry applications. Steel wire mesh offers several properties that make it ideal for use in this industry. Firstly, steel wire mesh is highly durable and can withstand harsh conditions, including extreme temperatures and corrosive environments. This is crucial in the oil and gas industry where equipment and infrastructure are exposed to corrosive substances and high-pressure environments. Additionally, steel wire mesh has excellent strength and can provide structural support and reinforcement in various applications such as fencing, filtration, and insulation. It can withstand heavy loads and is resistant to deformation, making it suitable for use in oil and gas pipelines, storage tanks, and processing equipment. Moreover, steel wire mesh can be manufactured to meet specific requirements, including mesh size, wire diameter, and material grade. This allows for customization to suit different applications, such as filtration for oil and gas separation or protection against debris and wildlife. Lastly, steel wire mesh is cost-effective and offers a long lifespan, reducing maintenance and replacement costs. Its availability and ease of installation also make it a practical choice for oil and gas industry applications. Overall, steel wire mesh is a reliable and versatile material that can meet the demanding needs of the oil and gas industry. Its strength, durability, customizability, and cost-effectiveness make it a suitable choice for various applications within this sector.

Send your message to us

Stainless Steel Decoration Chain link Fence for Garden

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords