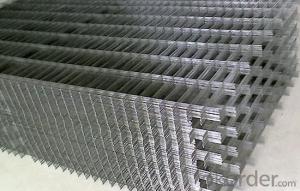

Welded Wire Mesh

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Place of Origin: | Wire diameter bias maximum | Model Number: | |||

| Type: | Application: | Hole Shape: | |||

| Aperture: | Material: | Wire Gauge: | |||

| Surface Treatment: | Weave Type: | Certificates: | |||

| Aperture bias maximum:: | : | |

Packaging & Delivery

| Packaging Detail: | 50-100 pcs into a bundle on a pallet,with plastic film inside |

| Delivery Detail: | 15-25days depend on the final order quantity |

Specifications

1.ISO9001:2008,SGS,BV,CE,etc

2.12 years Factory

3.For fixing heating pipe,reinforcing concrete construction,etc

4,Galvanized

Wire Diameter(mm) | Aperture | Width(mm) | Length | |

Inch | mm | |||

2.0mm-3.2mm | 1" | 25.4 | 1200-2400 | The length does not limit |

2.0mm-4.5mm | 2" | 50.8 |

| |

2.0mm-6.0mm | 3" | 70.2 | 0.914m-2.75m | |

2.0mm-6.0mm | 4" | 101.6 | 0.914m-2.75m | |

2.0mm-6.0mm | 5" | 127 | 0.914m-2.75m | |

2.0mm-6.0mm | 6" | 152.4 | 0.914m-2.75m | |

2.0mm-6.0mm | 7" | 177.8 | 0.914m-2.75m | |

2.0mm-6.0mm | 8" | 203.2 | 0.914m-2.75m | |

- Q: Can steel wire mesh be used for agricultural fencing?

- Agricultural fencing can indeed utilize steel wire mesh. Its durability and strength make it a popular choice. By offering a reliable and secure barrier, it effectively keeps livestock contained while safeguarding crops from wildlife. The tight weave of the mesh design prevents animals from escaping or getting entangled, making it suitable for cattle, horses, and sheep. Moreover, being resistant to corrosion, steel wire mesh can withstand outdoor elements, ensuring the longevity of the fence. In conclusion, steel wire mesh proves to be a practical and efficient solution for agricultural fencing.

- Q: How does steel wire mesh compare to other types of mesh materials?

- Steel wire mesh is highly regarded for its exceptional strength, durability, and versatility, making it superior to many other mesh materials. Unlike materials like plastic or nylon, steel wire mesh offers unmatched resistance to wear and tear, corrosion, and extreme temperatures. Its rigid structure ensures excellent structural integrity, making it suitable for a wide range of applications, including construction, industrial, and agricultural sectors. Additionally, steel wire mesh provides superior security, offering excellent protection against intruders and effectively containing materials or objects. Overall, steel wire mesh stands out as a reliable and long-lasting option that outperforms other mesh materials in terms of strength and functionality.

- Q: Is steel wire mesh resistant to vibration?

- Yes, steel wire mesh is generally resistant to vibration due to its strong and rigid structure.

- Q: What are the different wire mesh thicknesses available in steel wire mesh?

- Steel wire mesh is available in various thicknesses to cater to different applications and requirements. The most common thicknesses for steel wire mesh range from 0.5mm to 10mm. However, it is important to note that the thickness of wire mesh can vary based on the specific type and grade of steel being used. For lighter and more flexible applications, such as insect screens or decorative purposes, wire mesh with a thickness of 0.5mm to 1mm is commonly used. These thinner meshes provide adequate strength and durability while allowing for better visibility and airflow. In industrial and heavy-duty applications, thicker wire mesh is preferred. Wire mesh with a thickness ranging from 2mm to 10mm is commonly used for applications such as security fencing, machine guards, or reinforcement panels. Thicker meshes provide increased strength and resistance to wear, making them suitable for demanding environments. It is worth mentioning that wire mesh thickness is often referred to as the wire gauge, which provides a standardized measurement system. The wire gauge system assigns a number to each thickness, with a higher number indicating a thinner wire. This system can vary regionally, so it is essential to consider the specific gauge system being used when selecting wire mesh thickness. Ultimately, the choice of wire mesh thickness depends on the specific application and the level of strength, visibility, or airflow required. Consulting with a supplier or industry expert can help determine the most suitable thickness for your specific needs.

- Q: What are the electrical conductivity properties of steel wire mesh?

- Due to its high metal content, steel wire mesh possesses excellent electrical conductivity. Typically comprising iron and carbon, with trace amounts of other elements, the steel utilized in wire mesh allows for the unhindered movement of electrons, resulting in its role as a proficient conductor of electricity. The electrical conductivity of steel wire mesh can fluctuate based on several factors, including wire gauge, wire spacing, and overall mesh thickness. Generally, thicker wires which are more closely spaced contribute to enhanced conductivity. In applications necessitating electrical conductivity, steel wire mesh is frequently employed. Examples include electrical enclosures, grounding systems, and electromagnetic shielding. The mesh's conductivity properties facilitate the smooth flow of electric current, thereby minimizing the likelihood of electrical hazards and ensuring dependable electrical connections. Nonetheless, it is important to acknowledge that steel wire mesh may not be suitable for all electrical applications. In scenarios involving high frequencies or low resistance, materials such as copper or aluminum may offer superior conductivity. Furthermore, the presence of rust or corrosion on the wire mesh can detrimentally impact its electrical conductivity. Regular upkeep and proper maintenance are required to uphold optimal conductivity properties of steel wire mesh.

- Q: What are the different types of coatings used for steel wire mesh?

- Steel wire mesh can be coated with various types of coatings, each with its own unique properties and advantages. Some commonly used coatings for steel wire mesh include: 1. Galvanized Coating: Galvanization is a popular coating method for steel wire mesh. It involves applying a layer of zinc to the mesh surface, providing excellent corrosion resistance and durability. Galvanized coatings are available in two forms: hot-dip galvanized, which offers a thicker and more durable coating, and electro-galvanized, which provides a thinner but still effective corrosion protection. 2. PVC Coating: PVC coating is commonly used to provide additional protection against corrosion and abrasion for steel wire mesh. This coating is applied through extrusion, where a layer of melted PVC is bonded to the wire surface. PVC coatings also offer insulation, chemical resistance, and color options. 3. Epoxy Coating: Epoxy coatings are suitable for steel wire mesh that requires high chemical resistance and durability. They can be applied as liquid or powder coatings, forming a strong and protective layer on the mesh surface. Epoxy coatings have excellent adhesion, resistance to chemicals, abrasion, and impact. 4. Polyester Coating: Polyester coatings are known for their durability and resistance to UV radiation, making them ideal for outdoor applications. They are applied using a powder coating process, where a layer of polyester is electrostatically sprayed onto the wire mesh and then cured to form a tough and protective finish. 5. Polyethylene Coating: Polyethylene coatings are often used when the wire mesh needs protection against chemicals, moisture, and UV radiation. These coatings are applied through fusion bonding, where the polyethylene material is melted and adhered to the wire mesh surface. Polyethylene coatings provide excellent corrosion and abrasion protection. These examples demonstrate the variety of coatings available for steel wire mesh. The choice of coating depends on specific requirements such as corrosion resistance, durability, chemical resistance, and environmental factors. It is advisable to consult a knowledgeable supplier or coating specialist to determine the most suitable coating for a particular steel wire mesh application.

- Q: Can steel wire mesh be used for statues?

- Yes, steel wire mesh can definitely be used for statues. Steel wire mesh is a versatile material that can be shaped and manipulated into various forms, making it suitable for creating intricate and detailed sculptures. It offers structural support and stability, allowing sculptors to create larger and more complex statues. Additionally, the open design of the mesh allows for transparency, which can create interesting visual effects when combined with other materials or lighting. Steel wire mesh is also durable and weather-resistant, making it ideal for outdoor statues that need to withstand the elements. Overall, steel wire mesh offers sculptors a wide range of possibilities when it comes to creating statues, making it a popular choice in the art world.

- Q: Can steel wire mesh be used for window grilles?

- Yes, steel wire mesh can be used for window grilles. Steel wire mesh is a durable and strong material that can provide security for windows. It can be used to create a protective barrier that prevents unauthorized access and intrusion. The mesh is typically made from high-quality stainless steel, which makes it resistant to corrosion and weathering. Additionally, steel wire mesh can be customized to fit various window sizes and shapes, making it a versatile choice for window grilles.

- Q: How is steel wire mesh used in the manufacturing industry?

- Steel wire mesh is widely used in the manufacturing industry for a variety of applications. One of the primary uses of steel wire mesh is in the fabrication of screens and filters. These screens and filters are used to separate and sort materials, ensuring that only desired particles or components pass through while undesired ones are filtered out. This is especially important in industries such as mining, construction, and agriculture, where materials need to be sorted based on size or quality. Additionally, steel wire mesh is commonly used in the manufacturing of fencing and enclosures. It provides a strong and durable barrier, making it ideal for securing premises, protecting assets, or establishing boundaries. The versatility of steel wire mesh allows it to be customized to meet specific requirements, such as the size of the openings or the thickness of the wire, depending on the level of security needed. Another application of steel wire mesh in the manufacturing industry is in the reinforcement of concrete structures. The mesh is embedded within the concrete to provide tensile strength and prevent cracking. This reinforcement is particularly important in large-scale construction projects, such as bridges, highways, and buildings, where the concrete needs to withstand heavy loads or external forces. Furthermore, steel wire mesh is utilized in the manufacturing of various types of conveyor belts. These belts are widely used in industries such as food processing, packaging, and automotive manufacturing, where materials or products need to be transported efficiently and smoothly. The steel wire mesh provides the necessary strength, flexibility, and durability to withstand the demanding conditions of conveyor systems. In summary, steel wire mesh plays a crucial role in the manufacturing industry. Its versatility, strength, and durability make it a valuable material for applications such as screens and filters, fencing and enclosures, concrete reinforcement, and conveyor belts. Its wide range of uses highlights its importance in various manufacturing processes and industries.

- Q: What is the tensile strength of steel wire mesh?

- The tensile strength of steel wire mesh is determined by multiple factors, including the steel type, wire diameter, and manufacturing technique. Typically, steel wire mesh exhibits a substantial tensile strength, typically ranging from 50,000 to 150,000 pounds per square inch (PSI). Nevertheless, it is crucial to acknowledge that the precise tensile strength may fluctuate based on the particular type and grade of steel wire mesh employed. In order to obtain accurate specifications regarding the tensile strength of the steel wire mesh you are contemplating, it is advisable to consult the manufacturer or supplier.

Send your message to us

Welded Wire Mesh

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords