New Green PVC Coated Wire Mesh Fence with Multi-Purpose

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

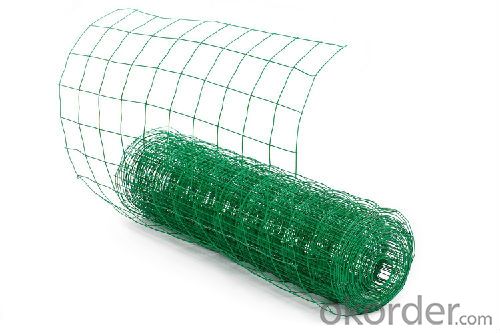

New Green PVC Coated Wire Mesh Fence with Multi-Purpose

1. Structure of PVC Coated Wire Mesh Fence Description:

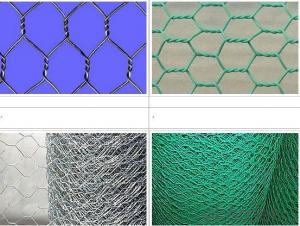

Hexagonal wire mesh is also called chicken wire, poultry netting ,rabbit netting. It is common used to fence chicken, poultry, rabbit and other animals.

The hexagonal wire mesh is made of black iron wire, galvanized iron wire, brass wire or stainless steel wire with hexagonal gaps, available in3/8 inch to 4inch ( 10mm to 100mm),wire gauge from BWG14 to BWG27 (2.1mm to 0.4mm).

Hexagonal wire mesh is extensively used in industrial and agricultural construction, building works, and all such made for the purpose of reinforcing and fencing as protective cage, guards for window and machinery safety isolation, floor screen reinforcement and poultry cage, fishing, garden and children's play-ground.

2. Main Features of PVC Coated Wire Mesh Fence :

• Firm structure,

• Flat surface

• Beautiful shape

• Oxidation –resistant

• Nice vision

• Good anti-corrosion

• Anti-oxidation

3. PVC Coated Wire Mesh Fence Images

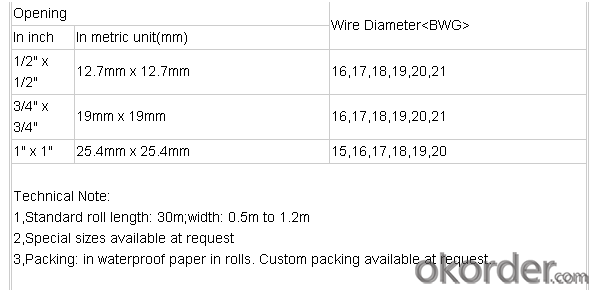

4. PVC Coated wire mesh Specification

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your PVC Coated wire mesh?

Our company is the professional manufacture of PVC Coated wire mesh and any other wire mesh. We have more than 15years experience in producing welded wire mesh. Based on our experience, with our reasonable price, high quality and considerate service, our products enjoy high reputation in our market. Our main products like PVC Coated wire mesh, hot rolled steel plate/coil, cold rolled steel coil, gi steel coil, pp gi coil, corrugated sheet, wire rod and so on. We have established business relationships with clients in the Southeast Asia,South Asia, North America, and many other countries and regions.

② The reason why you choose us

· Diversification of products

. Professional sales team

· Industry experience over 15 years

· Shipment of goods -More than 50 countries worldwide

· We have the most convenient transport and prompt delivery

· We offer competitive price with best service

· We have win high reputation based on best quality products

③ How long can we receive the product after purchase?

In the purchase of PVC Coated wire mesh within three working days, we will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served.

- Q: How does steel wire mesh perform in load-bearing capacity?

- Steel wire mesh is known for its exceptional load-bearing capacity. The interlocking nature of the wires creates a strong and rigid structure that can withstand heavy loads. The mesh is designed with high tensile strength, enabling it to resist stretching and deformation under pressure. This makes it suitable for a wide range of applications, including construction, fencing, and reinforcement in concrete structures. Additionally, steel wire mesh maintains its load-bearing capacity even in extreme conditions such as high temperatures or corrosive environments. Overall, steel wire mesh is a reliable and durable material that can effectively support heavy loads without compromising its structural integrity.

- Q: What are the different panel sizes available for steel wire mesh?

- The different panel sizes available for steel wire mesh can vary depending on the specific needs and requirements of the project. However, there are some standard panel sizes that are commonly available in the market. These typically range from 4 feet by 8 feet (122 cm by 244 cm) to 5 feet by 10 feet (152 cm by 305 cm). In addition to these standard sizes, custom panel sizes can also be manufactured to fulfill specific project requirements. This allows for flexibility in design and application, ensuring that the steel wire mesh can be tailored to fit the dimensions of the intended space. It is important to note that the availability of different panel sizes may vary depending on the supplier or manufacturer. Therefore, it is advisable to consult with the supplier or manufacturer to determine the exact panel sizes available for a specific steel wire mesh product.

- Q: How does steel wire mesh resist rust and corrosion?

- Steel wire mesh resists rust and corrosion due to its composition and protective coating. Steel wire mesh is typically made from stainless steel, which is an alloy that contains chromium. Chromium is known to have excellent corrosion resistance properties. It forms a passive oxide layer on the surface of the steel, which acts as a protective barrier against rust and corrosion. Additionally, steel wire mesh is often coated with a layer of zinc through a process called galvanization. Galvanization involves immersing the steel mesh in a bath of molten zinc. This creates a zinc-iron alloy on the surface, providing an extra layer of protection against rust and corrosion. The combination of stainless steel and galvanization makes steel wire mesh highly resistant to rust and corrosion. This makes it suitable for various applications, both indoors and outdoors, where exposure to moisture, humidity, and other corrosive elements is likely. Whether used in construction, fencing, or industrial applications, steel wire mesh offers durability and long-lasting performance in challenging environments.

- Q: Is steel wire mesh suitable for anti-theft applications?

- Yes, steel wire mesh is suitable for anti-theft applications. It is a strong and durable material that can provide an effective barrier against unauthorized entry or theft. The tight weave and high tensile strength of the steel wires make it difficult for intruders to cut through or break the mesh, making it an excellent choice for securing windows, doors, fences, or other vulnerable areas.

- Q: How does steel wire mesh perform in terms of light transmission?

- Steel wire mesh does not allow for light transmission as it is a dense and solid material that blocks the passage of light.

- Q: Is steel wire mesh suitable for landscape design?

- Steel wire mesh proves to be an ideal choice for landscape design. Its versatility allows for a multitude of applications that not only enhance the aesthetics but also the functionality of outdoor spaces. Whether it's for fencing, trellises, or screens, this material offers both boundaries and privacy while introducing a contemporary and industrial vibe to the landscape. Moreover, the construction of raised beds becomes effortless with steel wire mesh, offering flexibility and creativity in gardening options. Furthermore, it serves as a sturdy support structure for climbing plants, enabling the creation of stunning vertical gardens. Its enduring durability and strength guarantee a long-lasting option that withstands harsh weather conditions and resists corrosion. By seamlessly blending with different materials and styles, steel wire mesh unlocks limitless possibilities for landscape design.

- Q: Can steel wire mesh be used for creating cages or enclosures?

- Yes, steel wire mesh can be used for creating cages or enclosures. It is a strong and durable material that provides a secure barrier while allowing visibility and ventilation. Steel wire mesh is commonly used for constructing cages for animals, enclosures for gardens or farms, and various industrial applications requiring containment or protection.

- Q: Can steel wire mesh be used for waste management?

- Yes, steel wire mesh can be used for waste management. Steel wire mesh is a versatile and durable material that can be effectively utilized in various waste management processes. It can be used to create waste bins, containers, and enclosures, providing a secure and sturdy structure for managing waste. Steel wire mesh is known for its strength and resistance to corrosion, making it suitable for outdoor waste management applications. It can also be used as a filtering medium to separate solid waste from liquids or to create barriers to prevent waste from spreading or contaminating surrounding areas. Additionally, steel wire mesh can be used for composting systems, allowing airflow and proper drainage while keeping pests out. Overall, steel wire mesh is an excellent choice for waste management due to its strength, durability, and versatility in various waste management applications.

- Q: Can steel wire mesh be used for indoor applications?

- Indoor applications can indeed make use of steel wire mesh. This flexible material offers versatility and can be employed in a multitude of ways indoors, including partition walls, ceiling panels, decorative elements, and even furniture. With its strength, durability, and stability, steel wire mesh proves fitting for both aesthetic and functional purposes indoors. Moreover, the customization options for steel wire mesh are vast, encompassing size, shape, and pattern, thereby enabling a myriad of design possibilities.

- Q: How does steel wire mesh perform in high-temperature environments?

- Steel wire mesh performs well in high-temperature environments due to its excellent heat resistance properties. Steel is known for its high melting point and strength, allowing the wire mesh to retain its structural integrity even at elevated temperatures. It can withstand temperatures up to 1000 degrees Celsius without significant deformation or damage. Moreover, steel wire mesh has good thermal conductivity, which means it can efficiently distribute heat and prevent localized hotspots. This quality is crucial in high-temperature environments as it helps to prevent the wire mesh from overheating and maintains a more uniform temperature distribution. In addition to heat resistance, steel wire mesh also offers other benefits in high-temperature environments. It has high tensile strength, making it suitable for applications that require load-bearing capabilities. The inherent durability of steel ensures that the wire mesh can withstand harsh conditions without losing its functionality or structural integrity. Furthermore, steel wire mesh is corrosion-resistant, which is essential in high-temperature environments where oxidation and chemical reactions are common. It can resist the corrosive effects of hot gases and liquids, thereby prolonging its lifespan and minimizing maintenance requirements. Overall, steel wire mesh is a reliable and effective choice for use in high-temperature environments. Its heat resistance, thermal conductivity, strength, and corrosion resistance make it a versatile material capable of withstanding extreme temperatures while maintaining its structural integrity and performance.

Send your message to us

New Green PVC Coated Wire Mesh Fence with Multi-Purpose

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords