Galvanized Hexagonal Wire Netting Before Weaving

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Galvanized Hexagonal Wire Mesh Galvanized Hexagonal Wire Netting Before Weaving

Galvanized Hexagonal Wire Mesh is made of by high quality galvanized wire, Low carton steel wire, stainless steel wire, iron wire, Galvanized steel wire.

Application of Galvanized Hexagonal Wire Mesh Galvanized Hexagonal Wire Netting Before Weaving

Galvanized Hexagonal Wire Mesh is widely used in industrial and agricultural constructions, Rockwool, fence for poultry cage, fishing cage, playground fence and Christmas decorations

Surface treatment of Galvanized Hexagonal Wire Mesh Galvanized Hexagonal Wire Netting Before Weaving

a. Black (mild steel wire)

b. Electro galvanized, (galvanized before welding, galvanized after welding)

c. Hot dip galvanized, (galvanized before welding, galvanized after welding)

d. Stainless Steel Wire

Advantage of Galvanized Hexagonal Wire Mesh Galvanized Hexagonal Wire Netting Before Weaving

Our Galvanized Hexagonal Wire Mesh has strong corrosion-resisting and oxidation-resisting, stable shape, clean ends, good packing with good quality and rock bottom price.

Packing of Galvanized Hexagonal Wire Mesh Galvanized Hexagonal Wire Netting Before Weaving

1. Waterproof paper then PVC shrinked

2. PVC shrinked only

3. Black waterproof paper only

4. Waterproof paper then metal/wooden pallet

5. Plastic film then carton

(Also as your request. )

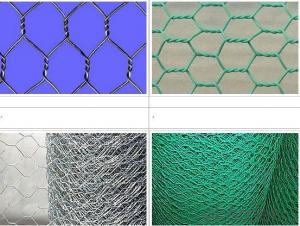

Pictures of Galvanized Hexagonal Wire Mesh Galvanized Hexagonal Wire Netting Before Weaving

Specification of Galvanized Hexagonal Wire Mesh

Mesh Opening | Wire Thickness | Width | |||

inch | mm | bwg | mm | inch | m |

3/8 | 10 | 27; 26; 25; 24; 23 | 0.40-0.63 | 12-48 | 0.3-1.2 |

1/2 | 13 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

5/8 | 16 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-48 | 0.3-1.2 |

3/4 | 19 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1 | 25 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1-1/4 | 30 | 24; 23; 22; 21; 20; 19; 18 | 0.56-1.25 | 12-48 | 0.3-1.2 |

1-1/2 | 40 | 23; 22; 21; 20; 19; 18 | 0.63-1.25 | 12-80 | 0.3-2.0 |

2 | 50 | 23; 22; 21; 20; 19; 18; 17 | 0.63-1.47 | 12-80 | 0.3-2.0 |

3 | 75 | 23; 22; 21; 20; 19; 18; 17; 16; 15 | 0.63-1.83 | 12-80 | 0.3-2.0 |

4 | 100 | 16; 15; 14; 13; 12 | 1.65-2.77 | 20-160 | 0.5-4.0 |

Mesh Opening | Wire Thickness | Width | |||

inch | mm | bwg | mm | inch | m |

1 | 25 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

1-1/4 | 30 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

1-1/2 | 40 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

2 | 50 | 25; 24; 23; 22; 21; 20; 19; 18; 17 | 0.51-1.47 | 12-80 | 0.3-2.0 |

3 | 75 | 23; 22; 21; 20; 19; 18; 17 | 0.63-1.47 | 12-80 | 0.3-2.0 |

FAQ

1. What is the storage condition?

The Galvanized Hexagonal Wire Mesh should be stored at room temperature and kept from wet and heat source.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Hot galvanized steel wire mesh and galvanized steel mesh how to identify?

- Hot galvanized and cold galvanized surface color is basically no difference but can be seen carefully the surface of the galvanized,

- Q: Can steel wire mesh be used for fire protection?

- Yes, steel wire mesh can be used for fire protection. Steel wire mesh is often used as a reinforcement material in concrete structures, including walls, floors, and roofs, to enhance their fire resistance properties. The mesh acts as a barrier that helps to prevent the spread of fire by providing additional strength and stability to the structure. Additionally, steel wire mesh can also be used as a protective covering for combustible materials, such as insulation or flammable cables, to minimize the risk of fire spreading. However, it is important to note that the effectiveness of steel wire mesh as a fire protection measure may vary depending on the specific application and fire safety requirements. It is recommended to consult with fire protection experts or refer to relevant building codes and regulations to ensure proper use and installation of steel wire mesh for fire protection purposes.

- Q: Can steel wire mesh be powder coated?

- Yes, steel wire mesh can be powder coated. Powder coating is a method of applying a dry powder paint onto a surface. The steel wire mesh is first cleaned and pre-treated to ensure proper adhesion of the powder coating. Then, the mesh is electrostatically charged and the powder is applied evenly to the surface. The coated mesh is then heated, causing the powder to melt and form a durable, protective finish. Powder coating is a popular choice for steel wire mesh as it provides excellent corrosion resistance, durability, and a wide range of color options.

- Q: What are the different edge treatments available for steel wire mesh?

- Steel wire mesh offers various edge treatments, each with a distinct purpose and unique advantages. One prevalent edge treatment is the selvage edge, which forms by looping the wire strands back into the mesh. This reinforcement prevents the mesh from unraveling or fraying, making it ideal for high tension or stress applications like fencing or industrial use. Another option is the knuckled edge, where wire strands are gently bent back in a curve. This type of edge is commonly found in chain link fencing, offering a safe and smooth edge that reduces the risk of injury and minimizes snagging or tearing of clothing and other materials. For applications requiring a sturdy and secure edge, a barbed or twisted edge can be employed. This involves bending the wire strands at the edge into sharp barbs or twists, ensuring extra security and preventing unauthorized access or tampering. Barbed or twisted edges are often utilized in high-security fencing or perimeter protection systems. In certain cases, a reinforced edge treatment may be necessary to enhance the mesh's strength and durability. This can be achieved by adding an extra layer of wire or a metal strip along the edge, promoting stability and preventing deformation or sagging. Ultimately, the choice of edge treatment for steel wire mesh depends on the specific application and requirements. Factors such as strength, safety, durability, and aesthetics should be considered when selecting the appropriate edge treatment. Seeking guidance from a knowledgeable supplier or manufacturer can help determine the most suitable edge treatment for a particular project.

- Q: Can steel wire mesh be used for conveyor belts?

- Certainly! Conveyor belts can indeed utilize steel wire mesh. Steel wire mesh proves to be a resilient and robust substance capable of enduring substantial weights and extreme temperatures, thus rendering it highly appropriate for conveyor belt purposes. Its exceptional strength and flexibility facilitate the seamless and efficient transportation of materials throughout the conveyor system. Moreover, the perforated structure of steel wire mesh permits effortless sanitation and drainage, making it particularly well-suited for sectors like food processing and agriculture. All in all, steel wire mesh represents a dependable and adaptable choice for conveyor belts.

- Q: Galvanized welded wire mesh and hot galvanized steel wire mesh What is the difference

- And insulation materials formed with the insulation layer together to form the external wall insulation system to effectively protect the residential envelope structure, so that the outside temperature changes, rain erosion on the building damage greatly reduced, thus solving the roof seepage, wall cracking and other chronic diseases

- Q: How does the coating affect the performance of steel wire mesh?

- The coating on steel wire mesh can have a significant impact on its performance. Firstly, the coating helps to protect the steel wire from corrosion and rust, which can greatly extend the lifespan of the mesh. This is particularly important when the wire mesh is exposed to harsh environments or moisture. Additionally, the coating can provide added strength and durability to the wire mesh. It can help to prevent deformation or breakage of the wires, especially when the mesh is subjected to heavy loads or tension. This is particularly crucial in applications where the wire mesh is used to support or reinforce structures. Furthermore, the coating on steel wire mesh can also enhance its appearance and improve its aesthetic appeal. It can provide a smooth and even surface, making the mesh more visually appealing and suitable for various architectural or decorative uses. Lastly, the coating can also influence the functionality of the steel wire mesh. Depending on the type of coating used, it can provide additional properties such as heat resistance, electrical conductivity, or resistance to chemicals. These properties can make the wire mesh suitable for a wide range of applications, including filtration, screening, fencing, and industrial uses. In summary, the coating plays a crucial role in enhancing the performance of steel wire mesh by protecting it from corrosion, providing strength and durability, improving aesthetics, and adding functional properties.

- Q: Can steel wire mesh be used for creating decorative wall panels?

- Certainly, decorative wall panels can indeed be created using steel wire mesh. The utilization of steel wire mesh brings about a one-of-a-kind and contemporary aesthetic that enhances the overall appearance and ambiance of any given space. It presents a robust and enduring solution for the formation of decorative wall panels, rendering it appropriate for both indoor and outdoor applications. The adaptability of steel wire mesh permits a multitude of design possibilities, encompassing diverse patterns, shapes, and sizes, thereby granting designers and homeowners the liberty to fashion personalized and visually captivating wall panels. Furthermore, steel wire mesh can be effortlessly manipulated and molded to suit various architectural designs, thus establishing it as a versatile material for the construction of decorative wall panels. All in all, steel wire mesh is a superb option for individuals seeking to infuse their walls with a contemporary and tasteful essence.

- Q: What are the weight and strength properties of steel wire mesh?

- Renowned for its exceptional strength and durability, steel wire mesh possesses certain weight and strength characteristics that depend on several factors, including the gauge of the wire, size of the mesh openings, and type of steel utilized. Regarding weight, steel wire mesh is relatively lightweight compared to solid steel materials of equivalent size and strength. This attribute facilitates easier handling and installation, particularly in large-scale applications like construction, fencing, and industrial environments. The weight of steel wire mesh can vary according to project-specific requirements, but it generally falls within a manageable range. Strength is a crucial attribute of steel wire mesh. Its tensile strength refers to its ability to endure stretching or pulling without breaking or deforming. Steel wire mesh displays high resilience and tensile strength, making it suitable for applications necessitating structural integrity and load-bearing capacities. The strength of steel wire mesh is determined by the thickness and quality of the wire employed. Thicker wires generally provide greater strength, while high-quality steel alloys enhance overall resilience and durability. This strength enables steel wire mesh to withstand heavy loads, resist impacts, and maintain its shape in diverse environmental conditions. Due to its excellent weight and strength properties, steel wire mesh is widely used in the construction, industrial, and agricultural sectors. It serves as a dependable material for reinforcing concrete structures, ensuring security and protection in fencing applications, and facilitating filtration and separation processes in industrial settings. In conclusion, steel wire mesh offers a balanced combination of weight and strength, making it a versatile and effective material in various applications. Its lightweight nature and exceptional strength make it a popular choice in industries where durability and reliability are of utmost importance.

- Q: What are the environmental benefits of using steel wire mesh?

- The environmental benefits of using steel wire mesh include its durability, recyclability, and low maintenance requirements. Steel wire mesh is resistant to harsh weather conditions and does not deteriorate easily, reducing the need for frequent replacements. Additionally, steel is a highly recyclable material, meaning that steel wire mesh can be repurposed or melted down for future use, reducing waste and conserving resources. Lastly, steel wire mesh generally requires low maintenance, resulting in less energy, water, and chemical usage compared to other materials.

Send your message to us

Galvanized Hexagonal Wire Netting Before Weaving

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords