Electric Galvanized Hexagonal Wire Netting for Rockwool

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Galvanized Hexagonal Wire Mesh for Rockwool

Galvanized Hexagonal Wire Mesh is made of by high quality galvanized wire, Low carton steel wire, stainless steel wire, iron wire, Galvanized steel wire.

Application of Galvanized Hexagonal Wire Mesh for Rockwool

Galvanized Hexagonal Wire Mesh is widely used in industrial and agricultural constructions, Rockwool, fence for poultry cage, fishing cage, playground fence and Christmas decorations

Surface treatment of Galvanized Hexagonal Wire Mesh for Rockwool

a. Black (mild steel wire)

b. Electro galvanized, (galvanized before welding, galvanized after welding)

c. Hot dip galvanized, (galvanized before welding, galvanized after welding)

d. Stainless Steel Wire

Advantage of Galvanized Hexagonal Wire Mesh for Rockwool

Our Galvanized Hexagonal Wire Mesh has strong corrosion-resisting and oxidation-resisting, stable shape, clean ends, good packing with good quality and rock bottom price.

Packing of Galvanized Hexagonal Wire Mesh for Rockwool

1. Waterproof paper then PVC shrinked

2. PVC shrinked only

3. Black waterproof paper only

4. Waterproof paper then metal/wooden pallet

5. Plastic film then carton

(Also as your request. )

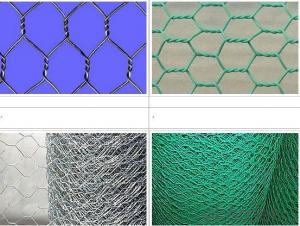

Pictures of Galvanized Hexagonal Wire Mesh for Rockwool

Specification of Galvanized Hexagonal Wire Mesh for Rockwool

Mesh Opening | Wire Thickness | Width | |||

inch | mm | bwg | mm | inch | m |

3/8 | 10 | 27; 26; 25; 24; 23 | 0.40-0.63 | 12-48 | 0.3-1.2 |

1/2 | 13 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

5/8 | 16 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-48 | 0.3-1.2 |

3/4 | 19 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1 | 25 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1-1/4 | 30 | 24; 23; 22; 21; 20; 19; 18 | 0.56-1.25 | 12-48 | 0.3-1.2 |

1-1/2 | 40 | 23; 22; 21; 20; 19; 18 | 0.63-1.25 | 12-80 | 0.3-2.0 |

2 | 50 | 23; 22; 21; 20; 19; 18; 17 | 0.63-1.47 | 12-80 | 0.3-2.0 |

3 | 75 | 23; 22; 21; 20; 19; 18; 17; 16; 15 | 0.63-1.83 | 12-80 | 0.3-2.0 |

4 | 100 | 16; 15; 14; 13; 12 | 1.65-2.77 | 20-160 | 0.5-4.0 |

Mesh Opening | Wire Thickness | Width | |||

inch | mm | bwg | mm | inch | m |

1 | 25 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

1-1/4 | 30 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

1-1/2 | 40 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

2 | 50 | 25; 24; 23; 22; 21; 20; 19; 18; 17 | 0.51-1.47 | 12-80 | 0.3-2.0 |

3 | 75 | 23; 22; 21; 20; 19; 18; 17 | 0.63-1.47 | 12-80 | 0.3-2.0 |

FAQ

1. What is the storage condition?

The Galvanized Hexagonal Wire Mesh should be stored at room temperature and kept from wet and heat source.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Can steel wire mesh be used for reinforcement of concrete?

- Concrete can be reinforced by using steel wire mesh. This type of mesh, also known as welded wire fabric or reinforcement mesh, is often utilized in concrete construction to improve the strength and longevity of concrete structures. It is made by welding steel wires together at their intersections, resulting in a grid-like pattern. Once created, this mesh is inserted into the concrete formwork before pouring the concrete. The steel wire mesh functions as reinforcement by distributing the tensile forces within the concrete, which is prone to cracking due to its low tensile strength. When concrete is subjected to external loads or temperature changes, it can experience tensile stress, leading to cracks. However, the steel wire mesh effectively holds the concrete together, reducing the likelihood of cracking and enhancing its overall strength. Furthermore, the use of steel wire mesh helps to control the size and propagation of any cracks that may occur. Acting as a barrier, the mesh prevents cracks from widening and spreading throughout the concrete structure. This not only improves the durability of the concrete but also enhances its resistance to deterioration, such as corrosion caused by moisture or chemicals. Moreover, steel wire mesh is relatively easy to handle and install, making it a convenient choice for reinforcement. It comes in various sizes and configurations, allowing for customization to meet specific project requirements. The mesh can be easily cut or bent to fit different shapes and sizes, making it adaptable for a wide range of concrete applications. In conclusion, steel wire mesh is a suitable and effective option for reinforcing concrete. Its ability to increase tensile strength, control crack propagation, and enhance durability makes it a commonly used material in concrete construction.

- Q: Is steel wire mesh suitable for marine applications?

- Steel wire mesh proves to be an excellent option for marine applications. With its exceptional strength and durability, it is well-suited for marine environments that expose it to harsh elements like saltwater, waves, and corrosive substances. Moreover, its resistance to rust and corrosion ensures a lengthy lifespan even in marine settings. Furthermore, steel wire mesh offers a high level of security and protection, making it appropriate for marine applications such as fencing, enclosures, and barriers. Its versatility allows for various uses in marine structures, including filtration, reinforcement, and containment. In summary, steel wire mesh is a dependable and efficient choice for marine applications due to its strength, durability, corrosion resistance, and ability to provide security and protection.

- Q: Can steel wire mesh be used for fireplace screens?

- Yes, steel wire mesh can be used for fireplace screens. Steel wire mesh is a durable and heat-resistant material, making it suitable for use as a fireplace screen. It can effectively prevent sparks and embers from escaping the fireplace and causing damage to the surrounding area. Additionally, steel wire mesh can provide a clear view of the fire while still ensuring safety. It is important to choose a steel wire mesh with appropriate gauge and spacing to ensure it can withstand the heat and effectively serve its purpose as a fireplace screen.

- Q: Can steel wire mesh be used for wire rope manufacturing?

- No, steel wire mesh cannot be used for wire rope manufacturing. Wire ropes are made by twisting multiple strands of steel wires together in a helical pattern, creating a strong and flexible rope. Steel wire mesh, on the other hand, is a grid-like structure made by weaving or welding steel wires together to create a mesh pattern. While both steel wire mesh and wire ropes are made of steel wires, they have different structures and properties. Therefore, steel wire mesh is not suitable for wire rope manufacturing.

- Q: How does steel wire mesh perform in sound absorption?

- When it comes to sound absorption, steel wire mesh falls short. The reason lies in steel's highly reflective nature, which hinders its ability to effectively absorb sound waves. Instead, steel wire mesh tends to bounce back and pass on sound waves, leading to minimal sound absorption capabilities. If your main concern is sound absorption, it is recommended to explore alternative materials like acoustic foam or fiberglass panels that are specifically engineered for this purpose.

- Q: Can steel wire mesh be used for gabion baskets?

- Yes, steel wire mesh can be used for gabion baskets. Gabion baskets are typically made from galvanized steel wire mesh, which provides strength, durability, and resistance to corrosion. The wire mesh is woven into a mesh pattern to create a flexible yet sturdy structure for retaining walls, erosion control, and other civil engineering applications.

- Q: What are the different flexibility options available for steel wire mesh?

- Some of the different flexibility options available for steel wire mesh include varying the wire gauge or thickness, altering the spacing or pattern of the mesh openings, using different weaving techniques such as plain or twill weave, and incorporating additional features like crimps or bends in the wire. These options allow for customization of the mesh to achieve desired levels of flexibility, rigidity, and structural integrity for specific applications.

- Q: What are the different wire mesh opening shapes available for steel wire mesh?

- Steel wire mesh offers a variety of wire mesh opening shapes, each with its own unique characteristics and applications. The first shape is the square opening, which is the most common and basic shape. It consists of evenly spaced wires intersecting at right angles, creating square openings. This versatile wire mesh is widely used in construction, filtration, and mining industries. Similar to the square shape, the rectangular opening has longer sides and is used when a higher aspect ratio is needed. It is commonly used for applications requiring a greater amount of material filtration or screening. The hexagonal opening, also known as hex wire mesh, features interlocking wires forming hexagonal openings. This flexible and strong mesh is commonly used for lightweight fencing, poultry enclosures, and gabion walls. Diamond-shaped openings are created by intersecting wires at acute angles. This shape provides excellent strength and is commonly used for security fencing, machine guards, and architectural applications. Round wire mesh features circular openings and is typically used for filtration applications, separating solids from liquids or gases. It is also popular for decorative purposes due to its pleasing appearance. Lastly, slotted wire mesh has elongated rectangular or oblong openings. It is commonly used for architectural purposes, such as building facades or decorative panels, as well as for sorting or sifting materials. These are just a few examples of the available wire mesh opening shapes for steel wire mesh. The choice of shape depends on specific application requirements, including desired strength, filtration capabilities, and aesthetics.

- Q: Can steel wire mesh be used for reinforcement in composite materials?

- Yes, steel wire mesh can be used for reinforcement in composite materials. Steel wire mesh is a versatile material that is commonly used to enhance the strength and durability of various construction materials, including composite materials. The mesh is typically made from high-strength steel wires that are woven or welded together to form a grid-like pattern. When incorporated into composite materials, the steel wire mesh acts as a reinforcement, providing additional structural integrity and improving the overall mechanical properties of the composite material. The steel wire mesh can be embedded within the composite material matrix, such as in a polymer resin, to distribute and absorb loads, enhance tensile strength, and increase resistance to cracking and deformation. The mesh effectively provides a framework that helps to prevent the propagation of cracks and improves the overall durability of the composite material. Furthermore, steel wire mesh can also be used as a surface layer reinforcement in composite materials. When applied as a surface layer, the mesh can prevent delamination and provide additional impact resistance. This is particularly useful in applications where the composite material is subjected to dynamic loads or impact forces. In conclusion, steel wire mesh is a suitable option for reinforcement in composite materials. Its high strength, durability, and versatility make it an effective solution for improving the mechanical properties and overall performance of composite materials.

- Q: Is steel wire mesh suitable for agricultural fencing?

- Yes, steel wire mesh is suitable for agricultural fencing. Steel wire mesh is a durable and strong material that provides excellent security and protection for agricultural areas. It is resistant to corrosion and can withstand harsh weather conditions, making it a long-lasting fencing option. The small gaps in the mesh allow for visibility and airflow, ensuring that crops and livestock can be monitored and kept safe. Additionally, steel wire mesh can be easily tailored to fit various sizes and shapes, making it versatile for different agricultural fencing needs. Overall, steel wire mesh is a reliable and effective choice for agricultural fencing.

Send your message to us

Electric Galvanized Hexagonal Wire Netting for Rockwool

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords