Electric Redrawing Galvanized Hexagonal Wire Netting

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

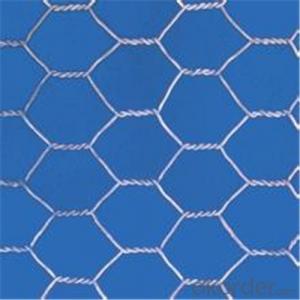

Introduction of Electric Redrawing Galvanized Hexagonal Wire Netting

Galvanized Hexagonal Wire Mesh is made of by high quality galvanized wire, Low carton steel wire, stainless steel wire, iron wire, Galvanized steel wire.

Application of Electric Redrawing Galvanized Hexagonal Wire Netting

Galvanized Hexagonal Wire Mesh is widely used in industrial and agricultural constructions, Rockwool, fence for poultry cage, fishing cage, playground fence and Christmas decorations

Surface treatment of Electric Redrawing Galvanized Hexagonal Wire Netting

a. Black (mild steel wire)

b. Electro galvanized, (galvanized before welding, galvanized after welding)

c. Hot dip galvanized, (galvanized before welding, galvanized after welding)

d. Stainless Steel Wire

Advantage of Electric Redrawing Galvanized Hexagonal Wire Netting

Our Galvanized Hexagonal Wire Mesh has strong corrosion-resisting and oxidation-resisting, stable shape, clean ends, good packing with good quality and rock bottom price.

Packing of Electric Redrawing Galvanized Hexagonal Wire Netting

1. Waterproof paper then PVC shrinked

2. PVC shrinked only

3. Black waterproof paper only

4. Waterproof paper then metal/wooden pallet

5. Plastic film then carton

(Also as your request. )

Pictures of Electric Redrawing Galvanized Hexagonal Wire Netting

Specification of Galvanized Hexagonal Wire Mesh

Mesh Opening | Wire Thickness | Width | |||

inch | mm | bwg | mm | inch | m |

3/8 | 10 | 27; 26; 25; 24; 23 | 0.40-0.63 | 12-48 | 0.3-1.2 |

1/2 | 13 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

5/8 | 16 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-48 | 0.3-1.2 |

3/4 | 19 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1 | 25 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1-1/4 | 30 | 24; 23; 22; 21; 20; 19; 18 | 0.56-1.25 | 12-48 | 0.3-1.2 |

1-1/2 | 40 | 23; 22; 21; 20; 19; 18 | 0.63-1.25 | 12-80 | 0.3-2.0 |

2 | 50 | 23; 22; 21; 20; 19; 18; 17 | 0.63-1.47 | 12-80 | 0.3-2.0 |

3 | 75 | 23; 22; 21; 20; 19; 18; 17; 16; 15 | 0.63-1.83 | 12-80 | 0.3-2.0 |

4 | 100 | 16; 15; 14; 13; 12 | 1.65-2.77 | 20-160 | 0.5-4.0 |

Mesh Opening | Wire Thickness | Width | |||

inch | mm | bwg | mm | inch | m |

1 | 25 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

1-1/4 | 30 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

1-1/2 | 40 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

2 | 50 | 25; 24; 23; 22; 21; 20; 19; 18; 17 | 0.51-1.47 | 12-80 | 0.3-2.0 |

3 | 75 | 23; 22; 21; 20; 19; 18; 17 | 0.63-1.47 | 12-80 | 0.3-2.0 |

FAQ

1. What is the storage condition?

The Galvanized Hexagonal Wire Mesh should be stored at room temperature and kept from wet and heat source.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Can steel wire mesh be used as a decorative element?

- Certainly, steel wire mesh serves as an excellent decorative component. With its versatility, steel wire mesh can be manipulated and shaped into various designs and patterns, offering endless possibilities. Whether it be for interior or exterior spaces, this material can be utilized to create unique and visually appealing features. For instance, it can be used as decorative panels, screens, or partitions, bringing a modern and industrial touch to any given area. Moreover, it can be employed as a backdrop for lighting fixtures or as a support for climbing plants, providing a natural and organic element to the overall decor. Furthermore, steel wire mesh can be coated or painted in different colors, allowing it to effortlessly complement any desired style or theme. Its strength and durability make it an ideal choice for both functional and decorative purposes, thus making it a popular option among architects, designers, and homeowners.

- Q: Is steel wire mesh suitable for use in solar panel installations?

- Yes, steel wire mesh is suitable for use in solar panel installations. It provides a durable and reliable support structure that can withstand various weather conditions and protect the solar panels from potential damage. Additionally, steel wire mesh offers sufficient ventilation, allowing for proper airflow and minimizing the risk of overheating.

- Q: Can steel wire mesh be customized in terms of wire thickness?

- Yes, steel wire mesh can be customized in terms of wire thickness. The wire thickness can be adjusted according to specific requirements and applications.

- Q: Can steel wire mesh be electroplated?

- Certainly! Electroplating is a method by which a thin layer of metal can be applied onto an object's surface through an electrochemical reaction. Steel wire mesh, for instance, has the capability to undergo this electroplating process. To achieve this, the steel wire mesh is submerged in an electrolyte solution that contains metal ions of the desired plating material, such as chromium or nickel. By passing an electric current through the solution, the metal ions are attracted to the steel wire mesh and form a metallic coating on its surface. Through this electroplating process, the steel wire mesh gains several advantages, including improved aesthetics, enhanced resistance to corrosion, and increased durability.

- Q: How is steel wire mesh used in fencing?

- Steel wire mesh is commonly used in fencing due to its durability and strength. It is made by weaving thin steel wires together to form a grid pattern. This type of fencing offers numerous benefits and is preferred in various applications. Firstly, steel wire mesh fencing provides security. The tightly woven pattern prevents intruders from easily accessing the protected area. The strength of the steel wires makes it difficult for anyone to break through the fence, ensuring the safety of the property and its occupants. Secondly, steel wire mesh fencing is widely used in agricultural settings. It is often used to enclose livestock, creating a safe and secure area for animals to graze or be contained. The small grid size of the mesh prevents smaller animals from entering or leaving the enclosed area, while still allowing for proper air circulation and visibility. Additionally, steel wire mesh fencing is frequently used in construction sites and industrial areas. It acts as a barrier to prevent unauthorized access and protects workers and equipment from potential hazards. The strength and durability of steel wire mesh make it resistant to damage from external forces, such as impacts or vandalism, which is crucial in these high-risk environments. Moreover, steel wire mesh fencing is aesthetically pleasing. It can be coated with various materials, such as PVC or galvanized coatings, to enhance its appearance and provide protection against corrosion. This allows the fence to blend seamlessly with its surroundings while maintaining its functionality. Lastly, steel wire mesh fencing is versatile and can be customized to meet specific requirements. It can be easily installed on different types of terrain and can be adjusted to different heights and lengths, depending on the needs of the project. Additionally, it can be combined with other fencing materials, such as barbed wire or electric fencing, to further enhance security. In conclusion, steel wire mesh is used in fencing due to its durability, strength, security, versatility, and aesthetic appeal. It is a popular choice in various applications, including residential, agricultural, industrial, and commercial settings, where safety and protection are of utmost importance.

- Q: How does steel wire mesh perform in high-impact applications?

- Due to its inherent strength and durability, steel wire mesh is highly effective in high-impact applications. The solid and rigid framework created by the interlocking nature of the mesh structure enables it to withstand significant force and impact. By evenly distributing the force across its surface area, the steel wire mesh prevents localized stress concentrations and potential damage. This capability allows the mesh to absorb and dissipate the energy generated during impact, thus minimizing the risk of deformation, breakage, or failure. Furthermore, steel wire mesh possesses excellent ductility, meaning it can deform under extreme loads while maintaining its structural integrity. This ability to effectively absorb and distribute impact energy makes steel wire mesh a perfect material for fencing, protective barriers, reinforcing concrete structures, and guarding industrial machinery.

- Q: How is steel wire mesh manufactured?

- Steel wire mesh is manufactured through a series of processes that involve transforming high-quality steel wire into a woven or welded mesh structure. The manufacturing process can vary depending on the desired specifications and application of the wire mesh. The first step in the manufacturing process is the selection of the appropriate type and grade of steel wire. This typically involves choosing a steel alloy that possesses the desired mechanical properties such as strength, ductility, and corrosion resistance. The selected steel wire is then drawn or rolled to reduce its thickness and increase its length, resulting in a long continuous wire. For woven wire mesh, the next step involves setting up a loom, which is a machine that interlaces the wires together to form a mesh. The wire is fed through a series of spools and guided through the loom, where it is interwoven with perpendicular wires. This process creates a mesh pattern with uniform openings. The mesh size and wire diameter can be adjusted by changing the spacing and tension of the wires during the weaving process. In the case of welded wire mesh, the steel wire is fed through a machine that straightens and cuts it into the desired length. The cut wire is then fed into a welding machine, where it is fused together at the intersection points to form a grid-like pattern. The welding process can be done using various techniques such as resistance welding, fusion welding, or spot welding. The resulting welded wire mesh has a strong and durable structure. After the weaving or welding process, the wire mesh is typically subjected to post-treatment processes to enhance its properties. This can include processes such as galvanization, where the mesh is coated with a layer of zinc to improve corrosion resistance, or PVC coating, where a layer of PVC is applied to provide additional protection and aesthetics. Finally, the finished steel wire mesh is inspected for quality control to ensure that it meets the required specifications and standards. This can involve checking the dimensions, mesh size, wire diameter, and overall integrity of the mesh. The mesh is then rolled or cut into the desired lengths or sizes and packaged for shipment to customers. Overall, the manufacturing of steel wire mesh involves a combination of precision and mechanical processes to transform steel wire into a versatile and functional mesh product that finds applications in various industries such as construction, filtration, reinforcement, and security.

- Q: What are the different surface textures available for steel wire mesh?

- There are various surface textures available for steel wire mesh, including plain, galvanized, PVC coated, epoxy coated, and stainless steel.

- Q: Can steel wire mesh be used for safety barriers?

- Yes, steel wire mesh can be used for safety barriers. Steel wire mesh is a durable and sturdy material that can effectively provide protection and enhance safety in various applications such as construction sites, highways, and industrial areas. It can be easily installed and offers visibility while preventing unauthorized access or potential hazards.

- Q: Can steel wire mesh be used for HVAC systems?

- Yes, steel wire mesh can be used for HVAC systems. Steel wire mesh is commonly used in HVAC systems for various purposes such as air filtration, protection of equipment, and structural support. One of the most common applications of steel wire mesh in HVAC systems is as an air filter. Steel wire mesh filters are highly effective in trapping particles and contaminants in the air, improving indoor air quality and preventing them from entering the HVAC equipment. The mesh structure allows for proper airflow while still capturing particles, ensuring efficient filtration. Steel wire mesh is also used for protecting HVAC equipment and components. It can be used as a protective covering for condenser coils, fan guards, and other vulnerable parts of the system. The mesh provides a physical barrier against debris, insects, and other potential damage-causing factors, thus extending the lifespan of the equipment and preventing costly repairs. Furthermore, steel wire mesh is used for structural support in HVAC systems. It can be used as a reinforcement material for ductwork, providing strength and stability to the system. The mesh is often used in flexible ducts to maintain their shape and prevent collapse, ensuring proper airflow throughout the system. Overall, steel wire mesh is a versatile material that can be effectively used in HVAC systems. Its ability to provide air filtration, equipment protection, and structural support makes it a valuable component in maintaining the functionality and efficiency of HVAC systems.

Send your message to us

Electric Redrawing Galvanized Hexagonal Wire Netting

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords