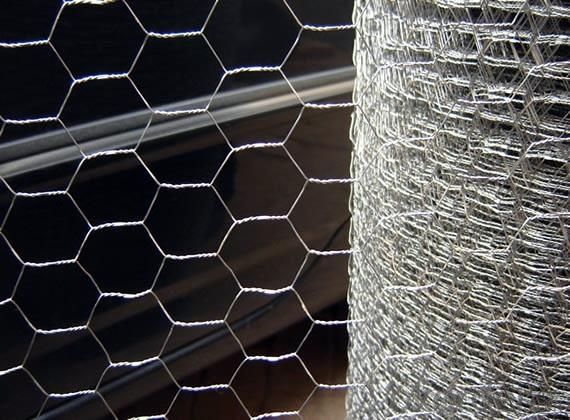

Hexagonal Galvanized Wire Netting After Weaving

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Galvanized Hexagonal Wire Mesh

Galvanized Hexagonal Wire Mesh is made of by high quality galvanized wire, Low carton steel wire, stainless steel wire, iron wire, Galvanized steel wire.

Application of Galvanized Hexagonal Wire Mesh

Galvanized Hexagonal Wire Mesh is widely used in industrial and agricultural constructions, Rockwool, fence for poultry cage, fishing cage, playground fence and Christmas decorations

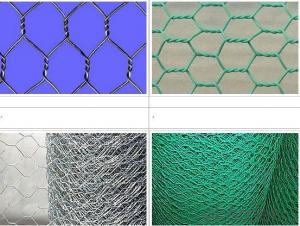

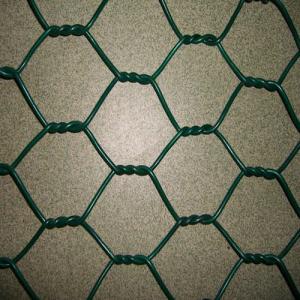

Surface treatment of Galvanized Hexagonal Wire Mesh

a. Black (mild steel wire)

b. Electro galvanized, (galvanized before welding, galvanized after welding)

c. Hot dip galvanized, (galvanized before welding, galvanized after welding)

d. Stainless Steel Wire

Advantage of Galvanized Hexagonal Wire Mesh

Our Galvanized Hexagonal Wire Mesh has strong corrosion-resisting and oxidation-resisting, stable shape, clean ends, good packing with good quality and rock bottom price.

Packing of Galvanized Hexagonal Wire Mesh

1. Waterproof paper then PVC shrinked

2. PVC shrinked only

3. Black waterproof paper only

4. Waterproof paper then metal/wooden pallet

5. Plastic film then carton

(Also as your request. )

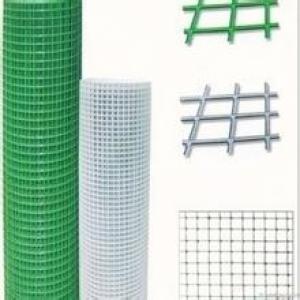

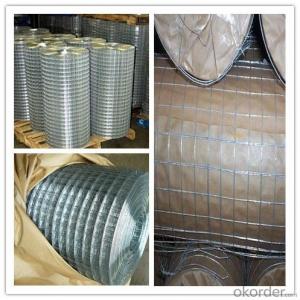

Pictures of Galvanized Hexagonal Wire Mesh

Specification of Galvanized Hexagonal Wire Mesh

Mesh Opening | Wire Thickness | Width | |||

inch | mm | bwg | mm | inch | m |

3/8 | 10 | 27; 26; 25; 24; 23 | 0.40-0.63 | 12-48 | 0.3-1.2 |

1/2 | 13 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

5/8 | 16 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-48 | 0.3-1.2 |

3/4 | 19 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1 | 25 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1-1/4 | 30 | 24; 23; 22; 21; 20; 19; 18 | 0.56-1.25 | 12-48 | 0.3-1.2 |

1-1/2 | 40 | 23; 22; 21; 20; 19; 18 | 0.63-1.25 | 12-80 | 0.3-2.0 |

2 | 50 | 23; 22; 21; 20; 19; 18; 17 | 0.63-1.47 | 12-80 | 0.3-2.0 |

3 | 75 | 23; 22; 21; 20; 19; 18; 17; 16; 15 | 0.63-1.83 | 12-80 | 0.3-2.0 |

4 | 100 | 16; 15; 14; 13; 12 | 1.65-2.77 | 20-160 | 0.5-4.0 |

Mesh Opening | Wire Thickness | Width | |||

inch | mm | bwg | mm | inch | m |

1 | 25 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

1-1/4 | 30 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

1-1/2 | 40 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

2 | 50 | 25; 24; 23; 22; 21; 20; 19; 18; 17 | 0.51-1.47 | 12-80 | 0.3-2.0 |

3 | 75 | 23; 22; 21; 20; 19; 18; 17 | 0.63-1.47 | 12-80 | 0.3-2.0 |

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. What is the storage condition?

The Galvanized Hexagonal Wire Mesh should be stored at room temperature and kept from wet and heat source.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Is steel wire mesh resistant to pests and rodents?

- Steel wire mesh boasts exceptional resistance against pests and rodents due to its robust and enduring composition. The formidable strength of steel wire renders the mesh impervious to chewing or fragmentation by pests. Unlike plastic or wood, steel wire mesh is not susceptible to infiltration, thus serving as a highly efficient deterrent. Moreover, the minute gaps between the wires effectively prevent rodents from squeezing through. Consequently, steel wire mesh finds widespread utilization in diverse applications, including fencing, screens, and cages, to effectively safeguard against pests and rodents.

- Q: How is steel wire mesh used in reinforcement of civil engineering projects?

- Steel wire mesh is commonly used in the reinforcement of civil engineering projects due to its strength and durability. It is typically employed in various applications such as concrete slabs, walls, columns, and beams to enhance their structural integrity and prevent cracks or failure. In concrete construction, steel wire mesh acts as a reinforcing material that provides tensile strength to the structure. It helps distribute the load evenly, reducing the risk of cracks caused by excessive stress or shrinkage. The mesh is typically placed in the middle of the concrete slab or wall during the pouring process, ensuring that it remains embedded within the concrete. This reinforcement significantly improves the structural stability and longevity of the project. The use of steel wire mesh also facilitates the construction of thinner concrete elements. By adding an additional layer of reinforcement, engineers can reduce the thickness of the concrete while maintaining its strength and load-bearing capacity. This not only saves on material costs but also makes the project more efficient and aesthetically pleasing. Moreover, steel wire mesh can be shaped or bent to fit specific areas, making it suitable for irregular or complex structures. It is also commonly used in seismic-prone areas, as it helps absorb and dissipate the energy generated during earthquakes, reducing the potential damage to the structure. Overall, steel wire mesh plays a crucial role in reinforcing civil engineering projects by providing strength, flexibility, and stability. Its use ensures the structural integrity and durability of concrete elements, making it an essential component in various construction applications.

- Q: Can steel wire mesh be used for creating sports field fences or cages?

- Certainly, sports field fences or cages can indeed be created using steel wire mesh. This versatile material presents numerous advantages for this purpose. With its strength and durability, steel wire mesh is capable of withstanding the heavy impact of sports activities, making it an ideal choice for enclosing sports fields. Furthermore, it allows for excellent visibility, ensuring that spectators can view the game unobstructed. In addition to this, steel wire mesh provides security by effectively preventing unauthorized access to the field or cage. Moreover, it can be tailored to specific size and design requirements, making it suitable for a wide range of sports fields or cages. All in all, steel wire mesh proves to be a reliable and practical material for the construction of sports field fences or cages.

- Q: How is steel wire mesh used in reinforcement of slabs?

- To enhance the structural integrity and durability of slabs, steel wire mesh is commonly employed for reinforcement. This mesh consists of interconnected steel wires arranged in a grid pattern, which adds strength to the concrete slab. When utilizing steel wire mesh for slab reinforcement, it is typically positioned in the middle of the concrete slab, slightly above the bottom layer. The mesh is carefully placed to ensure uniform coverage throughout the slab's area and is secured in place using support chairs or steel rebar. The primary objective of steel wire mesh reinforcement is to manage cracking and provide tensile strength to the concrete slab. Since concrete is strong when compressed but weak when subjected to tension, the mesh aids in evenly distributing tensile forces across the slab's surface, preventing the formation and propagation of cracks. Additionally, this reinforcement enhances the slab's resistance to bending and shear forces, thereby reducing the risk of structural failure. Apart from augmenting the slab's strength, steel wire mesh reinforcement offers other advantages as well. It enhances the overall durability of the slab by mitigating the impact of temperature and shrinkage-related stresses. Furthermore, it helps minimize the effects of ground settling or shifting beneath the slab. Moreover, steel wire mesh reinforcement can be employed to reinforce thinner slabs, reducing the amount of concrete required and resulting in cost savings during construction. Its ease of installation also makes it a practical choice for various construction projects. In conclusion, steel wire mesh is an indispensable element in slab reinforcement as it significantly enhances strength, durability, and resistance to cracking. Whether utilized in residential, commercial, or industrial applications, this reinforcement method ensures that the concrete slab can withstand the loads and forces it will encounter throughout its lifespan.

- Q: Can steel wire mesh be used for signage or advertising displays?

- Yes, steel wire mesh can be used for signage or advertising displays. Steel wire mesh is a versatile and durable material that can be easily shaped and manipulated to create various forms of signage and advertising displays. It provides a unique and modern aesthetic, making it an attractive choice for businesses looking to stand out. Steel wire mesh can be used to create large-scale outdoor signs, as well as smaller indoor displays. It can be custom-made to fit specific dimensions and designs, allowing for a high level of creativity and customization. The open structure of the wire mesh also allows for airflow and visibility, making it suitable for outdoor settings where wind resistance is important. Furthermore, steel wire mesh can be combined with other materials, such as LED lights, to create eye-catching and illuminated signage. It can also be coated or painted in various colors to match a company's branding or desired aesthetic. Overall, steel wire mesh is a versatile and durable material that can be effectively utilized for signage and advertising displays. Its unique appearance and customization options make it a popular choice for businesses looking to create impactful and visually appealing advertising.

- Q: What are the different mesh shape options available for steel wire mesh?

- The different mesh shape options available for steel wire mesh include square, rectangular, hexagonal, diamond, and woven wire mesh.

- Q: How is steel wire mesh used in the automotive manufacturing industry?

- Steel wire mesh is commonly used in the automotive manufacturing industry for various purposes. It is primarily used for reinforcing and strengthening car parts, such as doors, hoods, and trunks, to enhance structural integrity and improve safety. Additionally, steel wire mesh is utilized in the fabrication of air filters, radiator grills, and speaker covers, providing protection against debris and ensuring efficient functioning of these components. Its versatility and durability make steel wire mesh an essential material in the automotive industry.

- Q: What are the different fastening methods for steel wire mesh?

- Steel wire mesh can be secured in various applications using different fastening methods. Some commonly used methods include: 1. Industrial settings often utilize welding as a popular fastening method for steel wire mesh. By melting the wire mesh and adjoining material, a strong bond is created. This method is ideal for permanent installations that require strength and durability. 2. Quick and easy, zip ties (also known as cable ties or wire ties) are a popular choice for fastening steel wire mesh. These plastic ties are threaded through the mesh and tightened to secure it. Zip ties are commonly used in temporary installations or situations where frequent adjustments are necessary. 3. When securing steel wire mesh panels together, clips and clamps are commonly employed. These accessories, made of metal or plastic, grip the edges of the mesh to hold it in place. Clips and clamps provide a secure and reliable fastening method while allowing for easy disassembly and reassembly if needed. 4. Screws or nails can also be used to fasten steel wire mesh, especially in construction and woodworking projects. This method is suitable when the mesh needs to be attached to a solid substrate like wood or metal. Screws and nails offer a sturdy and permanent fastening solution. 5. Cable lacing, also known as lacing cord or lacing wire, is a traditional method of fastening steel wire mesh. It involves threading a thin wire or cord through the mesh and securely tying it. Cable lacing is often used in applications that require flexibility and adjustability. 6. Adhesives can be an option for fastening steel wire mesh to surfaces. Specialized adhesives designed for bonding metal can be applied to the mesh and substrate, creating a strong and permanent bond. However, this method should be carefully considered based on specific requirements and conditions. Overall, the choice of fastening method for steel wire mesh depends on factors such as the application, installation requirements, and desired permanence. Strength, durability, and ease of installation should all be considered when selecting the appropriate method for a specific project.

- Q: What are the different grades of steel used for wire mesh?

- Wire mesh can be made from various grades of steel, including low carbon steel, medium carbon steel, high carbon steel, and stainless steel. The choice of grade depends on the intended application and the desired strength, corrosion resistance, and durability of the wire mesh.

- Q: What are the different wire mesh coatings available for steel wire mesh?

- There are several different wire mesh coatings available for steel wire mesh, each offering specific benefits and properties. 1. Galvanized Coating: This is one of the most common and traditional coatings for steel wire mesh. It involves applying a layer of zinc to the surface of the mesh to protect it from corrosion and rust. Galvanized coatings are highly durable and provide excellent resistance to moisture and outdoor elements. 2. PVC Coating: PVC (Polyvinyl Chloride) coating is applied to steel wire mesh to enhance its resistance to corrosion, chemicals, and abrasion. This coating also adds an extra layer of insulation and provides a smooth and attractive finish to the mesh. PVC coated wire mesh is commonly used in applications where aesthetics and protection against harsh environments are important. 3. Epoxy Coating: Epoxy coatings offer superior adhesion and chemical resistance compared to other coatings. They are highly durable and provide excellent protection against corrosion, impact, and abrasion. Epoxy coated wire mesh is commonly used in industrial settings where exposure to chemicals, moisture, and harsh conditions is expected. 4. Polyester Coating: Polyester coatings are known for their excellent resistance to UV radiation, chemicals, and weathering. They provide a smooth and colorful finish to the wire mesh and are often used in architectural applications where aesthetics and durability are essential. 5. Polyethylene Coating: Polyethylene coatings are applied to steel wire mesh to provide protection against corrosion, chemicals, and abrasion. They offer excellent resistance to UV radiation and are commonly used in outdoor applications like fences, enclosures, and animal cages. 6. Stainless Steel Coating: Stainless steel wire mesh does not require any additional coating as it is already highly resistant to corrosion and rust. Stainless steel provides excellent strength and durability, making it suitable for applications that require high strength and hygiene, such as food processing and pharmaceutical industries. It is important to choose the appropriate wire mesh coating based on the specific requirements of the application, such as environmental conditions, desired durability, and aesthetics. Consulting with a wire mesh supplier or expert can help determine the most suitable coating for a particular use.

Send your message to us

Hexagonal Galvanized Wire Netting After Weaving

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords