Hot dipped Galvanized Hexagonal Wire Netting after Weaving for Chicken

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

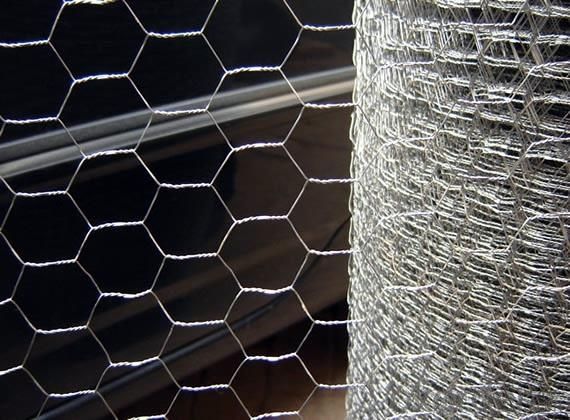

Introduction of Galvanized Hexagonal Wire Mesh after weaving for Chicken

Galvanized Hexagonal Wire Mesh is made of by high quality galvanized wire, Low carton steel wire, stainless steel wire, iron wire, Galvanized steel wire.

Application of Galvanized Hexagonal Wire Mesh for Chicken

Galvanized Hexagonal Wire Mesh is widely used in industrial and agricultural constructions, Rockwool, fence for poultry cage, fishing cage, playground fence and Christmas decorations

Surface treatment of Galvanized Hexagonal Wire Mesh after weaving for Chicken

a. Black (mild steel wire)

b. Electro galvanized, (galvanized before welding, galvanized after welding)

c. Hot dip galvanized, (galvanized before welding, galvanized after welding)

d. Stainless Steel Wire

Advantage of Galvanized Hexagonal Wire Mesh after weaving for Chicken

Our Galvanized Hexagonal Wire Mesh has strong corrosion-resisting and oxidation-resisting, stable shape, clean ends, good packing with good quality and rock bottom price.

Packing of Galvanized Hexagonal Wire Mesh for Chicken

1. Waterproof paper then PVC shrinked

2. PVC shrinked only

3. Black waterproof paper only

4. Waterproof paper then metal/wooden pallet

5. Plastic film then carton

(Also as your request. )

Pictures of Galvanized Hexagonal Wire Mesh for Chicken

Specification of Galvanized Hexagonal Wire Mesh

Mesh Opening | Wire Thickness | Width | |||

inch | mm | bwg | mm | inch | m |

3/8 | 10 | 27; 26; 25; 24; 23 | 0.40-0.63 | 12-48 | 0.3-1.2 |

1/2 | 13 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

5/8 | 16 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-48 | 0.3-1.2 |

3/4 | 19 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1 | 25 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1-1/4 | 30 | 24; 23; 22; 21; 20; 19; 18 | 0.56-1.25 | 12-48 | 0.3-1.2 |

1-1/2 | 40 | 23; 22; 21; 20; 19; 18 | 0.63-1.25 | 12-80 | 0.3-2.0 |

2 | 50 | 23; 22; 21; 20; 19; 18; 17 | 0.63-1.47 | 12-80 | 0.3-2.0 |

3 | 75 | 23; 22; 21; 20; 19; 18; 17; 16; 15 | 0.63-1.83 | 12-80 | 0.3-2.0 |

4 | 100 | 16; 15; 14; 13; 12 | 1.65-2.77 | 20-160 | 0.5-4.0 |

Mesh Opening | Wire Thickness | Width | |||

inch | mm | bwg | mm | inch | m |

1 | 25 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

1-1/4 | 30 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

1-1/2 | 40 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

2 | 50 | 25; 24; 23; 22; 21; 20; 19; 18; 17 | 0.51-1.47 | 12-80 | 0.3-2.0 |

3 | 75 | 23; 22; 21; 20; 19; 18; 17 | 0.63-1.47 | 12-80 | 0.3-2.0 |

FAQ

1. What is the storage condition?

The Galvanized Hexagonal Wire Mesh should be stored at room temperature and kept from wet and heat source.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served

- Q: Is steel wire mesh suitable for use in railway infrastructure?

- Steel wire mesh is well-suited for railway infrastructure due to its strength, durability, and resistance to corrosion. This material is ideal for a variety of applications in railway infrastructure. For instance, it can be used to fence off railway tracks, ensuring safety and preventing unauthorized access. Additionally, steel wire mesh provides stability and support by reinforcing concrete structures like bridges, tunnels, and platforms. It is also effective for controlling erosion and stabilizing slopes in railway embankments. Overall, steel wire mesh offers numerous advantages in terms of strength, longevity, and versatility, making it a fitting option for railway infrastructure.

- Q: How does the diameter of the wire affect the strength of steel wire mesh?

- The diameter of the wire has a direct impact on the strength of steel wire mesh. As the diameter of the wire increases, the strength of the wire mesh also increases. This is because a thicker wire is able to withstand higher tension and resist deformation or breakage more effectively. The strength of steel wire mesh is primarily determined by the tensile strength of the individual wires used to create the mesh. Tensile strength refers to the maximum amount of tensile stress a material can withstand before failure. Thicker wires have a higher tensile strength, which means they can withstand greater forces without breaking. In addition to the tensile strength, the diameter of the wire also affects the rigidity and stability of the mesh. Thicker wires provide more stability and make the mesh less susceptible to sagging or bending under heavy loads. This is particularly important in applications where the wire mesh is used for structural or support purposes. Moreover, the diameter of the wire also impacts the open area or aperture size of the mesh. Thicker wires reduce the size of the openings and increase the density of the mesh. This can be beneficial in applications where a higher level of security, privacy, or protection is required. However, it is important to note that while a thicker wire generally results in a stronger wire mesh, it also increases the weight and cost of the mesh. Therefore, the diameter of the wire should be carefully chosen based on the specific requirements of the application, striking a balance between strength, weight, and cost.

- Q: What are the benefits of using steel wire mesh in the chemical industry?

- Using steel wire mesh in the chemical industry has several advantages: 1. Chemical Resistance: Steel wire mesh displays high resistance to a variety of chemicals and corrosive substances. It can endure exposure to acids, alkalis, solvents, and other aggressive chemicals commonly found in the chemical industry. This resistance guarantees the mesh's longevity and durability, even in harsh chemical environments. 2. Strength and Durability: Steel wire mesh possesses excellent strength and durability properties, making it suitable for heavy-duty applications in the chemical industry. It can withstand high temperatures, extreme pressures, and mechanical stresses, making it ideal for use in chemical reactors, storage tanks, and pipelines. 3. Filtration and Separation: Steel wire mesh can be woven into different mesh sizes and patterns, enabling effective filtration and separation of solids and liquids. It can be used for various filtration processes, such as removing impurities, separating different components, and enhancing the purity of chemicals. The mesh's high porosity ensures efficient flow rates and minimal pressure drops. 4. Safety and Protection: Steel wire mesh provides a protective barrier in the chemical industry, preventing accidental spills, leaks, or emissions of hazardous substances. It can be utilized as safety screens, containment enclosures, or protective covers for equipment and machinery. The mesh's robust nature ensures reliable protection against chemical hazards. 5. Easy Maintenance and Cleaning: Maintaining and cleaning steel wire mesh in the chemical industry is effortless. It can be easily washed, rinsed, or sterilized to eliminate any chemical residues or contaminants. This ease of maintenance guarantees hygienic conditions and prevents cross-contamination between different chemicals or processes. 6. Cost-effectiveness: Steel wire mesh offers a cost-effective solution in the chemical industry. Its long lifespan, low maintenance requirements, and resistance to chemical degradation reduce the need for frequent replacements or repairs. Furthermore, its versatility and adaptability make it a valuable investment for various applications, leading to overall cost savings. In conclusion, the utilization of steel wire mesh in the chemical industry provides numerous benefits, including chemical resistance, strength and durability, filtration and separation capabilities, safety and protection, easy maintenance and cleaning, and cost-effectiveness. These advantages establish steel wire mesh as the preferred choice for various critical processes and applications in the chemical industry.

- Q: Is steel wire mesh suitable for aquaculture applications?

- Indeed, aquaculture applications can find steel wire mesh to be a suitable choice. Renowned for its strength, durability, and resistance to corrosion, steel wire mesh possesses vital qualities in aquaculture settings. It serves as an excellent option for crafting cages, enclosures, or fencing that effectively contain and safeguard fish or other aquatic organisms. By customizing the mesh size, water flow can be regulated while preventing the intrusion of predators or escape of farmed species. Moreover, steel wire mesh can be effortlessly cleaned and maintained, ensuring a sanitary environment for aquaculture operations. Nonetheless, it is crucial to consider the specific requirements of the aquaculture system and the species being farmed to select the most appropriate mesh size and material.

- Q: Can steel wire mesh be used for sunshade?

- Yes, steel wire mesh can be used for sunshade. It is a durable and strong material that can effectively block sunlight and provide shade in various outdoor settings.

- Q: What are the different types of steel wire mesh?

- There are several different types of steel wire mesh available, each with its own unique characteristics and applications. Some of the most common types include: 1. Welded Wire Mesh: This type of steel wire mesh is created by electrically welding the wires at their intersections. It is known for its strength and durability, making it suitable for a wide range of applications such as construction, fencing, and reinforcement in concrete structures. 2. Woven Wire Mesh: This type of steel wire mesh is created by weaving the wires together in a pattern, resulting in a flexible and versatile material. It is commonly used in filtration, screening, and separation applications due to its ability to provide precise and consistent openings. 3. Expanded Metal Mesh: This type of steel wire mesh is created by expanding a sheet of metal and creating diamond-shaped openings. It is known for its rigidity and strength, making it suitable for industrial applications such as walkways, fencing, and security panels. 4. Perforated Metal Mesh: This type of steel wire mesh is created by punching or drilling holes in a sheet of metal. It provides a high level of ventilation, while also offering strength and stability. It is commonly used in architectural and decorative applications, as well as for filtration and screening purposes. 5. Crimped Wire Mesh: This type of steel wire mesh is created by weaving the wires together in a crimped pattern. It offers a high level of structural stability and is commonly used in mining, quarrying, and aggregate processing applications. 6. Knitted Wire Mesh: This type of steel wire mesh is created by interlocking the wires together in a knitted pattern. It is known for its flexibility and ability to conform to irregular shapes, making it suitable for applications such as gaskets, seals, and filtration. Overall, the different types of steel wire mesh offer a wide range of options to suit various applications, providing strength, durability, flexibility, and precision as required.

- Q: Can steel wire mesh be used for creating safety nets?

- Yes, steel wire mesh can be used for creating safety nets. Steel wire mesh is known for its strength and durability, making it an ideal material for safety nets. It is able to withstand heavy loads and provide a secure barrier, making it suitable for applications such as construction sites, sports arenas, and even playgrounds. Steel wire mesh can be customized to meet specific safety requirements, such as mesh size and strength, ensuring that it can effectively protect people from falling or hazardous objects. Additionally, steel wire mesh is resistant to corrosion, which makes it suitable for outdoor use and ensures a long lifespan for the safety nets.

- Q: What are the different gauges available in steel wire mesh?

- The different gauges available in steel wire mesh range from thin to thick, typically measured in terms of wire diameter. Common gauges include 18, 16, 14, 12, and 10, with lower numbers representing thicker wire. The specific gauge chosen depends on the intended use and desired strength of the mesh.

- Q: What are the maintenance requirements for steel wire mesh?

- Steel wire mesh requires minimal maintenance, but it is still crucial to regularly inspect and clean it to ensure it lasts long and functions properly. Here are some essential maintenance guidelines for steel wire mesh: 1. Regularly clean the mesh to remove any accumulated dirt, debris, or contaminants. Use a brush or cloth to wipe away dirt, and for stubborn stains, utilize a mild detergent or non-abrasive cleaner. 2. Prevent rust formation by keeping the mesh dry and avoiding contact with corrosive substances or moisture. Applying a protective coating like paint or a rust-resistant spray can also help prevent rust. 3. Inspect the mesh regularly for damage, such as tears, holes, or loose connections, to maintain its structural integrity. Promptly repair any damages to prevent further deterioration and potential safety hazards. 4. Lubricate moving parts, such as hinges or joints, if present in the steel wire mesh. Use a lubricant specifically designed for metal surfaces to reduce friction and prevent wear and tear. 5. Protect the mesh from extreme weather conditions like heavy rain, snow, or prolonged exposure to direct sunlight. Install a cover or shelter to shield the mesh from these elements. By adhering to these maintenance requirements, steel wire mesh can remain in excellent condition and continue to effectively and safely serve its intended purpose.

- Q: How does steel wire mesh perform in terms of UV resistance?

- Steel wire mesh typically has low resistance to UV radiation. Over time, prolonged exposure to UV rays can cause the steel wire mesh to weaken and deteriorate. This is because the UV rays can break down the protective coatings on the mesh, leading to corrosion and eventually compromising its structural integrity. To prevent or minimize the effects of UV radiation, steel wire mesh can be treated with specialized coatings or paints that provide additional UV resistance. However, it is important to note that even with these protective measures, prolonged exposure to UV rays can still cause some level of degradation to the steel wire mesh. Therefore, if UV resistance is a critical factor, alternative materials such as plastic or fiberglass mesh may be more suitable for the intended application.

Send your message to us

Hot dipped Galvanized Hexagonal Wire Netting after Weaving for Chicken

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords