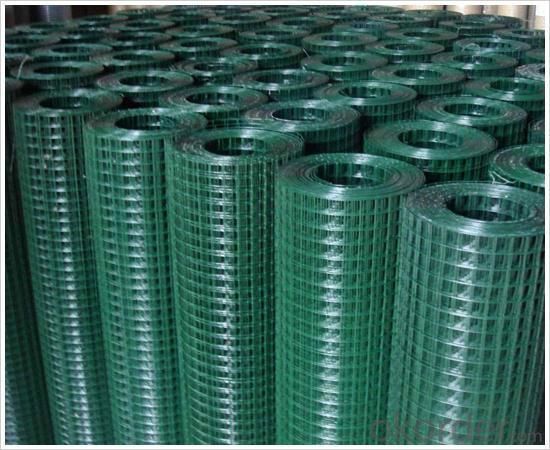

Welded Wire Mesh Panel with PVC Coating

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500rolls roll

- Supply Capability:

- 10000rolls roll/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

| Quick Detailes of PVC Welded Wire Mesh Panel | |

| Brand name | |

| Material | Low carbon steel wire, stainless steel wire |

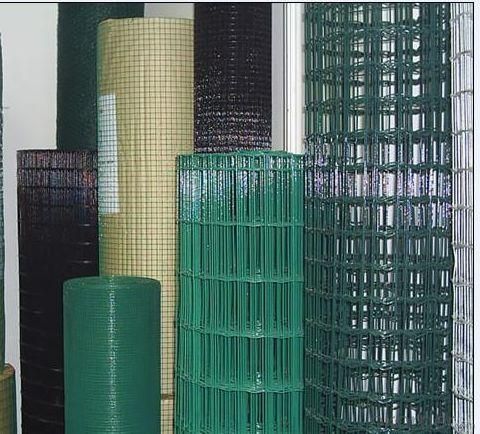

| Color | Green, red, yellow, white and so on. Dark Green is most popular |

| Packing | Wooden or Steel Pallets with PVC Film Covered |

| Origin | China |

| Export Markets | Global |

| Specifications of PVC Welded Wire Mesh Panel | |

| Size | Mesh Size:50× 200mm, 50× 150mm, 75× 150mm Wire Dia.:3.0-6.0mm |

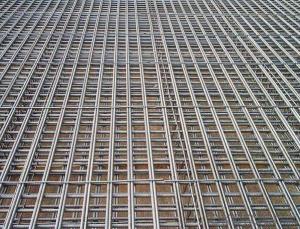

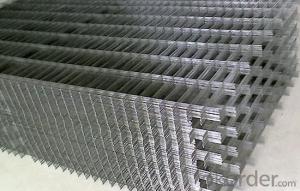

| Process | Welding--making folds---galvanized/hot-dipped---powder coated---packaging |

| Application | 1. It is used in highway, railway, 2. Expressway, airport, dock, port for security and safety; Fences for zoo, 3. Playground, grassland, pasture, garden, fences for protection of machine, 4. Flowers, trees, fences for protection of window, personal property |

| Features | 1. Protecting fence series post design makes it quick and easy installation with Fence, without any fasteners. 2. Any height fence panel can be installed in the post without bolts and nuts. After installed, the fence and post become a unremovale joint unit, to ensure The fence strength and security 3. Fence and post design have clear linellae, novelty apperance, rich of colors And models, perfect blend of the external environment. 4. Double anti-corrosion: Hot DIP galvanized (zinc coating thickness of 70g/ m2 Or more) and a specially designed adhesive layer and polyester coating (thicknessof about 700 μ M). |

Usage/Applications

Packaging & Delivery

- Q: How does steel wire mesh perform in extreme weather conditions?

- Steel wire mesh is known for its durability and strength, making it highly reliable in extreme weather conditions. It can effectively withstand high winds, heavy snow loads, and intense heat without compromising its structural integrity. Additionally, its corrosion-resistant properties help prevent rusting, making it suitable for both indoor and outdoor applications. Overall, steel wire mesh proves to be a resilient and dependable material in adverse weather conditions.

- Q: Is steel wire mesh resistant to rust or oxidation?

- Yes, steel wire mesh is resistant to rust and oxidation.

- Q: What are the common sizes and dimensions of steel wire mesh?

- There is a wide range of sizes and dimensions for steel wire mesh to cater to different applications and requirements. Here are some common specifications: 1. Mesh Size: Steel wire mesh is categorized based on the number of openings per linear inch, known as the mesh size. It is available in various mesh sizes such as 2, 4, 8, 10, 12, 16, 20, 30, 40, 50, 60, 80, 100, 120, 150, 200, and 400. The finer the wire mesh, the higher the mesh number. 2. Wire Diameter: Steel wire mesh has different wire diameters depending on the application. It can range from thin wires with diameters as small as 0.05 mm (0.002 inches) to thicker wires with diameters up to 6 mm (0.24 inches) or more. Wire diameter is often specified in gauge, with common gauges ranging from 6 to 24. 3. Sheet Size: Standard sheet sizes for steel wire mesh are usually 4 feet (1.2 meters) wide and 8 feet (2.4 meters) long. However, custom sizes can be manufactured to meet specific project requirements. 4. Opening Size: The openings in steel wire mesh can vary depending on the mesh size and wire diameter. Smaller openings are commonly used for fine filtration or insect screening, while larger openings are suitable for applications like fencing or construction reinforcement. Opening size can range from as small as 0.05 mm (0.002 inches) to several centimeters. It is important to note that these dimensions are not exhaustive, and variations in size and dimensions are available to fulfill specific needs. Consulting with a supplier or manufacturer is recommended to determine the most suitable steel wire mesh size and dimensions for a particular application.

- Q: What are the benefits of using steel wire mesh in the telecommunications infrastructure?

- There are several benefits of using steel wire mesh in the telecommunications infrastructure: 1. Durability: Steel wire mesh is known for its strength and durability. It can withstand harsh weather conditions, extreme temperatures, and other environmental factors, making it ideal for outdoor telecommunications applications. 2. Security: Steel wire mesh provides a high level of security for telecommunications infrastructure. It acts as a physical barrier, preventing unauthorized access to sensitive equipment and cables. This helps in safeguarding the network against potential threats and malicious activities. 3. Protection against electromagnetic interference (EMI): Steel wire mesh has excellent shielding properties, which help in reducing electromagnetic interference. This is crucial in telecommunications infrastructure, as EMI can disrupt signals and affect the overall performance of the network. 4. Flexibility: Steel wire mesh is highly flexible and can be easily molded to fit various shapes and sizes. This makes it adaptable to different installation requirements and allows for easy customization during the construction of telecommunications infrastructure. 5. Cost-effectiveness: Steel wire mesh is a cost-effective solution for telecommunications infrastructure. Its long lifespan and low maintenance requirements make it a financially viable option in the long run. Additionally, its ease of installation helps in reducing labor costs and overall project expenses. 6. Aesthetics: Steel wire mesh can be designed in various patterns and finishes, enhancing the aesthetics of telecommunications infrastructure. This is particularly important in urban areas, where the infrastructure needs to blend seamlessly with the surrounding environment. Overall, the use of steel wire mesh in telecommunications infrastructure offers numerous benefits, including durability, security, protection against EMI, flexibility, cost-effectiveness, and improved aesthetics.

- Q: Can steel wire mesh be used for insect screening?

- Yes, steel wire mesh can be used for insect screening. Steel wire mesh is known for its durability and strength, making it an effective material for keeping insects out of homes, buildings, and other enclosed spaces. The tight weave of the steel wire mesh prevents insects from entering while still allowing air circulation and visibility. Additionally, steel wire mesh is resistant to rust and corrosion, ensuring its longevity and effectiveness as an insect screen.

- Q: How is steel wire mesh used in reinforcement of water projects?

- Steel wire mesh is commonly used in the reinforcement of water projects to provide structural strength and support. It is used to reinforce concrete structures such as dams, reservoirs, and water treatment plants. The steel wire mesh is embedded within the concrete, creating a strong and durable bond that helps to prevent cracking and improve overall structural integrity. Additionally, the mesh helps to distribute the load evenly, reducing the risk of structural failure and ensuring the longevity of water projects.

- Q: How does steel wire mesh perform in high-pressure environments?

- Steel wire mesh is known for its exceptional strength and durability, making it highly suitable for high-pressure environments. When subjected to high pressure, steel wire mesh demonstrates excellent resistance against deformation and stretching, ensuring its structural integrity remains intact. This resilience is due to the inherent strength and rigidity of steel, which allows the wire mesh to withstand immense pressure without compromising its shape or performance. Additionally, steel wire mesh is highly resistant to corrosion, which further enhances its suitability for high-pressure environments. The steel material used in the wire mesh is often treated or coated to prevent rusting and corrosion, ensuring that it can withstand the harsh conditions associated with high-pressure environments, such as exposure to moisture, chemicals, or extreme temperatures. The interlocking nature of the wire mesh also contributes to its performance in high-pressure environments. The mesh pattern provides stability and prevents any potential weak points, distributing the pressure evenly throughout the entire surface. This distribution of pressure ensures that the wire mesh can withstand high-pressure conditions without experiencing localized stress concentrations that could lead to failure. Moreover, steel wire mesh offers excellent permeability, allowing for the flow of fluids, gases, or substances through its openings. In high-pressure environments, this permeability can be advantageous as it enables efficient filtration, separation, or containment of materials, while still maintaining the required pressure levels. In conclusion, steel wire mesh is a reliable and robust material for high-pressure environments. Its strength, corrosion resistance, interlocking structure, and permeability make it a suitable choice for applications where pressure resistance is crucial, such as in industrial processes, filtration systems, or high-pressure containment areas.

- Q: How does the coating affect the resistance of steel wire mesh to chemicals?

- The coating on steel wire mesh acts as a protective barrier that can significantly enhance its resistance to chemicals. It prevents direct contact between the chemicals and the steel, reducing the risk of corrosion and degradation. The type and quality of the coating can determine its effectiveness against various chemicals, as some coatings are specifically designed to resist certain substances. Overall, a well-applied and durable coating can greatly improve the resistance of steel wire mesh to chemicals, allowing it to withstand harsh environments and prolong its lifespan.

- Q: How does steel wire mesh perform in terms of resistance to weathering?

- Steel wire mesh is renowned for its remarkable ability to resist weathering. It is composed of robust and corrosion-resistant steel, enabling it to endure diverse weather conditions including rain, snow, heat, and UV exposure. Unlike other materials, steel wire mesh remains unaffected by warping, cracking, or degradation when exposed to these elements. To enhance its resistance to weather, the galvanization process is employed. This involves applying a protective layer of zinc to the steel wire mesh, serving as a moisture barrier and preventing rust formation. Consequently, this additional layer fortifies the mesh, augmenting its durability and extending its lifespan. Moreover, steel wire mesh exhibits exceptional performance in terms of withstanding extreme temperatures. It does not become brittle in cold climates nor compromise its structural integrity in high temperatures. Consequently, it proves suitable for a myriad of applications, including outdoor fencing, construction endeavors, and agricultural uses. Additionally, steel wire mesh showcases impressive resistance to wind and impact. Its inherent strength and flexibility allow it to endure strong gusts without bending or breaking. Hence, it serves as an optimal choice for applications where wind loads are a concern, such as coastal areas or high-rise buildings. All in all, steel wire mesh emerges as an outstanding choice for outdoor applications due to its exceptional resistance to weathering. Its capacity to withstand various weather conditions, coupled with its galvanized coating, resistance to extreme temperatures, and wind resistance, render it a dependable and long-lasting option for a diverse array of projects.

- Q: What are the benefits of using steel wire mesh in the transportation industry?

- Using steel wire mesh in the transportation industry offers numerous advantages. To begin with, steel wire mesh is extremely durable and can withstand heavy loads and harsh weather conditions. This makes it perfect for tasks such as cargo containment, securing loads on trucks and trailers, and protecting transportation infrastructure. Additionally, steel wire mesh provides excellent visibility and airflow. Its open design allows for clear sightlines, which are crucial for drivers to observe their surroundings and enhance road safety. Moreover, the open structure promotes airflow, preventing the accumulation of heat and moisture. This is especially beneficial when transporting perishable goods or livestock. Furthermore, steel wire mesh is cost-effective and requires low maintenance. Its long lifespan and resistance to corrosion make it a reliable and economical choice for the transportation industry. Unlike other materials, steel wire mesh does not need frequent repairs or replacements, reducing maintenance costs and downtime. Moreover, steel wire mesh is versatile and customizable. It can be fabricated into different shapes and sizes to suit various transportation needs. Whether it is utilized as a barrier, partition, or reinforcement, steel wire mesh can be tailored to specific requirements, offering flexibility and adaptability in the transportation industry. Lastly, steel wire mesh is environmentally friendly. It is made from recyclable materials and can be reused or repurposed, minimizing waste and promoting sustainability. Additionally, its open structure allows for natural light penetration, reducing the dependence on artificial lighting and saving energy. In conclusion, the usage of steel wire mesh in the transportation industry provides benefits such as durability, visibility, airflow, cost-effectiveness, versatility, and environmental friendliness. These advantages make steel wire mesh an excellent choice for various applications, enhancing safety, efficiency, and sustainability in the transportation sector.

SUNRISE,it is a factory which is specially in welded wire mesh, Euro mesh, welded mesh panels. All our products are backed by our Quality Management system which has been approved and accredited by the CQC to ISO. Welcome to vist us .

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2004 |

| Annual Output Value | Above US$ more than 100,000,000 |

| Main Markets | Mid East; Eastern Europe and America; North America; and other coutries |

| Company Certifications | ISO 9001:2008;CE; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 70% |

| No.of Employees in Trade Department | 60 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 15,000 square meters |

| No. of Production Lines | Above 5 producce line, 120 units machine |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | reasonable; Average; lower |

Send your message to us

Welded Wire Mesh Panel with PVC Coating

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500rolls roll

- Supply Capability:

- 10000rolls roll/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords