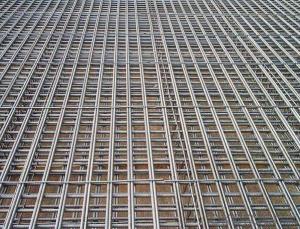

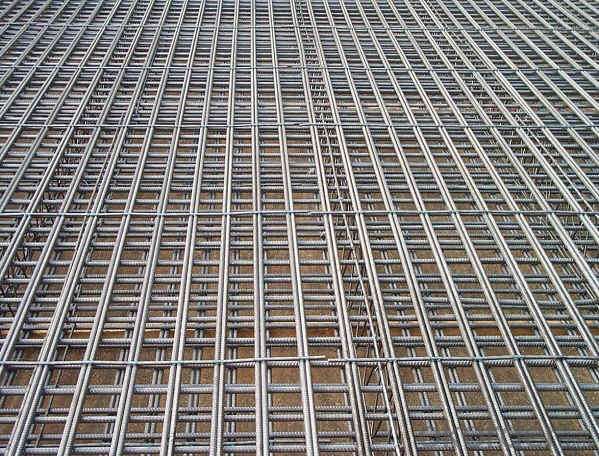

Galvanized Reinforcement Concrete steel wire mesh

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel bar welded wire mesh Introduction:

Steel bar welded wire mesh is also called welded steel fabric, steel welding nets, steel welding nets, steel bar welded mesh, steel mesh and so on. Is the longitudinal reinforcement and transverse reinforcement were arranged in a certain interval and at right angles to each other, all the intersections are welded together.

Steel bar wire mesh Description:

Material: low carbon steel bar, thread steel bar, thread rod

1.Mesh width: 0.5 m - 2.4 m;

2.Wire diameter3.0-10.0 (mm);

3.Apertures: 50x50mm,100x100mm,150x150mm,200x200mm

4.length: below 12m

5.Application: construction,bridge,tunnel

6.Mesh size: 6 x2.4m

Product feature:

1.It has a strong and firm body, can bear the high pressure from the concrete and exterior.

The reinforcing mesh can save much man-haur, reduce the material cost in the process.

2.The reinforcing mesh can design by the project requirement, improve the efficiency and

bond to the concrete can meet the special construct needs.

It is widely use in airport, tunnel, bridge, highway and wharf, also in the construction of building floor, wall, roof and balcony.

Applications:

1. Concrete footpaths

2. Precast Panel construction

3. Construction reinforcement

4. Residential slabs and footings

5. Industrial and commercial ground slabs

Specification:

| WIRE DIAMETER | MESH | |

| Inch | MM | |

| 1.5mm | 1/2" X 1/2" | 12.7mm X 12.7mm |

| 2mm | 1" X 1" | 25.4mm X 25.4mm |

| 3mm | 1" X 1" | 25.4mm X 25.4mm |

| 3mm | 1-1/4" X 1-1/4" | 31.7mm X 31.7mm |

| 4mm | 1-1/2" X 1-1/2" | 38mm X 38mm |

| 4mm | 1-1/2" X 1-1/2" | 38mm X 38mm |

| 4mm | 1-1/2" X 1-1/2" | 38mm X 38mm |

| 2mm | 2" X 2" | 50.8mm X 50.8mm |

| 3mm | 2" X 2" | 50.8mm X 50.8mm |

| 3mm | 2" X 2" | 50.8mm X 50.8mm |

| 4mm | 2" X 2" | 50.8mm X 50.8mm |

| 4mm | 2" X 2" | 50.8mm X 50.8mm |

| 4mm | 2" X 2" | 50.8mm X 50.8mm |

| 4mm | 2" X 2" | 50.8mm X 50.8mm |

| 5mm | 2" X 2" | 50.8mm X 50.8mm |

| 5mm | 2" X 2" | 50.8mm X 50.8mm |

| 6mm | 4" X 2" | 101.6mm X 50.8mm |

| 6mm | 4" X 4" | 101.6mm X 101.6mm |

Delivery Time:

Within one week for one 20' container.

- Q: What are the benefits of using steel wire mesh in the automotive recycling industry?

- There are several benefits of using steel wire mesh in the automotive recycling industry. Firstly, steel wire mesh provides strong and durable containment for various types of materials, ensuring that they are securely transported and stored. It also allows for proper ventilation and drainage, preventing the accumulation of moisture or other potentially damaging elements. Additionally, steel wire mesh is highly resistant to corrosion and wear, making it a long-lasting and cost-effective solution. It can be easily cleaned and maintained, reducing the risk of contamination. Lastly, steel wire mesh is malleable, allowing for customization and flexibility to meet specific industry needs.

- Q: How does the roll size affect the ease of installation of steel wire mesh?

- The roll size of steel wire mesh can affect the ease of installation. Smaller roll sizes are generally easier to handle and maneuver, making them more convenient for installation. They can be easily transported to the desired location and are less likely to get tangled or damaged during the process. On the other hand, larger roll sizes can be more challenging to handle and may require additional manpower or equipment. They may also be more difficult to transport and maneuver into position. Therefore, smaller roll sizes tend to offer greater ease of installation compared to larger ones.

- Q: How does steel wire mesh resist rust and corrosion?

- Steel wire mesh resists rust and corrosion due to its composition and protective coating. The steel used in the mesh is typically made from iron alloyed with carbon and other elements, which gives it inherent resistance to rust. Additionally, the mesh is often coated with materials such as zinc or PVC, which act as a barrier against moisture and corrosive substances. These protective measures effectively prevent the steel wire mesh from rusting and corroding, ensuring its durability and longevity.

- Q: How does steel wire mesh perform in terms of load distribution?

- Steel wire mesh performs very well in terms of load distribution. Due to its interconnected network of steel wires, it effectively transfers and distributes the load evenly across its structure. This characteristic is particularly beneficial in applications where a heavy load needs to be supported, such as in construction, industrial settings, or infrastructure projects. The mesh's grid-like pattern ensures that the load is spread out over a larger surface area, minimizing the concentration of stress points. This helps prevent localized failures or deformation in the mesh and the surrounding structures. Additionally, the high tensile strength of steel wire mesh allows it to withstand substantial loads without losing its structural integrity. Furthermore, steel wire mesh can be customized to meet specific load requirements. By varying the wire diameter, mesh opening size, or the spacing between wires, the load distribution capacity can be tailored to suit the intended application. This versatility makes steel wire mesh an ideal choice for a wide range of load-bearing applications. Overall, steel wire mesh offers excellent load distribution capabilities, ensuring the even distribution of weight and minimizing the risk of structural failures. Its strength, durability, and customizable nature make it a reliable and effective choice for various industries.

- Q: Can steel wire mesh be bent?

- Yes, steel wire mesh can be bent. Steel wire mesh is a flexible material that can easily be manipulated into various shapes and forms. It can be bent using different tools, such as pliers or wire cutters, to achieve the desired shape or curvature. The flexibility of steel wire mesh allows it to be used in a wide range of applications, including construction, landscaping, and industrial purposes. However, the degree to which steel wire mesh can be bent may depend on its thickness and strength. Thicker and stronger wire mesh may require more force or specialized equipment to bend.

- Q: What is the difference between alkali-resistant fiberglass mesh and hot-dip galvanized steel wire mesh?

- Alkali-resistant mesh cloth is only enhanced in the direction of the tensile strength of the direction of the vertical direction of the strength of no significant improvement, after the destruction of the surface are concentrated in the fiberglass mesh surface, whether using single-layer fiberglass mesh or Double-layer fiberglass mesh is not recommended with a tile finish.

- Q: How does steel wire mesh perform in terms of durability and long-term use?

- Steel wire mesh is highly durable and designed for long-term use. It is made from strong and resilient steel wires that are resistant to corrosion, rust, and physical damage. This durability allows the wire mesh to withstand harsh environmental conditions, heavy loads, and frequent use without losing its integrity. Moreover, steel wire mesh maintains its structural stability over time, making it a reliable choice for various applications such as construction, fencing, and industrial purposes.

- Q: Is steel wire mesh suitable for use in wastewater treatment plants?

- Yes, steel wire mesh is suitable for use in wastewater treatment plants. Steel wire mesh is a versatile and durable material that can withstand harsh conditions and provide effective filtration and separation capabilities. It is commonly used in wastewater treatment plants for various applications such as screening, filtering, and dewatering. Steel wire mesh offers excellent strength and stability, making it capable of withstanding high pressures and flow rates commonly found in wastewater treatment processes. It can effectively retain solid particles, debris, and other impurities while allowing the passage of water. This helps in removing contaminants and improving the overall quality of the treated water. Furthermore, steel wire mesh is resistant to corrosion, chemicals, and extreme temperatures, making it suitable for use in the aggressive and demanding environment of wastewater treatment plants. It is also easy to clean and maintain, ensuring a longer lifespan and cost-effectiveness. Overall, steel wire mesh is a reliable and efficient material choice for wastewater treatment plants due to its durability, versatility, and resistance to harsh conditions.

- Q: What are the anti-slip properties of steel wire mesh?

- Steel wire mesh has excellent anti-slip properties due to its textured surface and high coefficient of friction. The interwoven wire strands create a rough and stable surface, providing a secure grip for pedestrians and vehicles, even in wet or slippery conditions.

- Q: How is steel wire mesh used in reinforcement of manufacturing facilities?

- Manufacturing facilities commonly use steel wire mesh for various purposes in their reinforcement. A primary application is in concrete reinforcement, where the steel wire mesh is embedded within the concrete structure. This enhances the structural integrity and load-bearing capacity of the concrete, which is particularly important for facilities using heavy machinery and equipment. The presence of steel wire mesh prevents concrete structures from cracking, sagging, or failing. In addition to concrete reinforcement, steel wire mesh is also utilized for reinforcing walls and partitions within manufacturing facilities. This provides added strength and stability to ensure that these walls can withstand external forces and pressures. This is especially crucial in facilities with high vibrations or potential impacts, such as those caused by heavy machinery or forklift movements. Furthermore, steel wire mesh serves safety purposes in manufacturing facilities. It can be installed as a protective barrier around hazardous areas or machinery to prevent accidents and injuries. Acting as a physical barrier, steel wire mesh allows visibility and ventilation while restricting access to dangerous areas. Moreover, steel wire mesh finds application in the reinforcement of storage racks and shelves within manufacturing facilities. Incorporating wire mesh panels or decking in these storage systems improves their structural integrity, enabling the safe and efficient storage of heavy items and materials. Overall, steel wire mesh is an indispensable component in the reinforcement of manufacturing facilities. Its versatility, durability, and strength make it an ideal choice for enhancing the structural integrity of concrete, walls, partitions, and storage systems, while also providing crucial safety measures. Consequently, steel wire mesh ensures a safe and efficient working environment in manufacturing facilities.

Send your message to us

Galvanized Reinforcement Concrete steel wire mesh

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords