Concrete Reinforcing Welded Wire Mesh / Trench mesh / steel concrete mesh

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

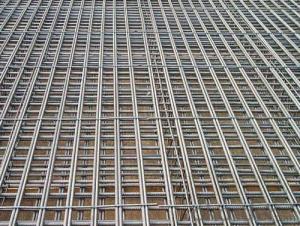

Reinforcing wire mesh is a welded wire fabric, prefabricated steel reinforcement material.

The fabric is used to provide tensile strength and crack control to structural concrete elements.

Specifications

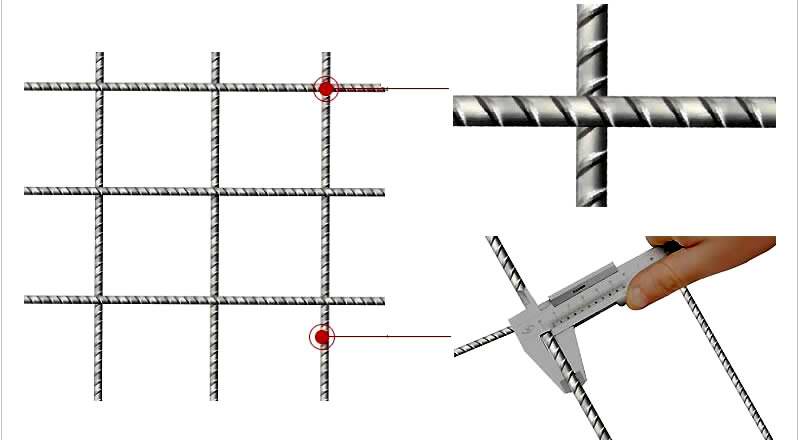

Wire diameter: 3mm to 12mm

Line wire spacing: min100 mm. larger line wire spacing in steps of 50 mm

Cross wire spacing: min 25mm. above programmable in increments of 0.1 mm

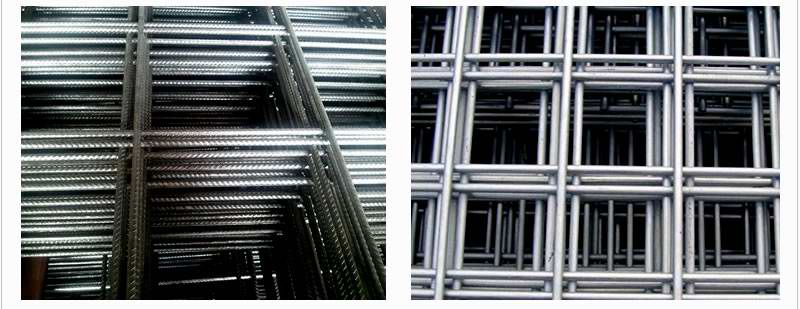

Wire mesh length: 500- 12000 mm

Wire mesh width: 500- 3300 mm

It's made of Deformed Steel Bars or Steel Rod.

Specification of Reinforcing Mesh

DIN488 GERMAN STANDARD (SIZE:2150MMX5000MM)

| Ref No. | Std Unit | Longitudinal Wires mm | Cross Wires mm | Pitch of wire | Mass Kg | Mass Kg/m2 |

| Q131 | Sheet | 5 | 5 | 150 @ 150 | 22.476 | 2.091 |

| Q188 | Sheet | 6 | 6 | 150 @ 150 | 32.401 | 3.014 |

| Q221 | Sheet | 6.5/5.0 | 6.5 | 150 @ 150 | 33.707 | 3.136 |

| Q295 | Sheet | 7.5/5.5 | 7.5 | 150 @ 150 | 44.245 | 4.116 |

| Q378 | Sheet | 8.5/6 | 8.5 | 150 @ 150 | 66.659 | 5.157 |

AS/NZS 4671:2001 Australia/New Zealand Standard (SIZE:6000X2400mm)

| Ref No. | Std Unit | Longitudinal Wires mm | Edge Wires mm | Cross Wires mm | Mass Kg |

| SL81 (F81) | Sheet | 7.6 @ 100 | 7.60 @ 100 | 7.60 @ 100 | 105 |

| SL102 (F102) | Sheet | 9.5 @ 200 | 6.75 @ 100 | 9.50 @ 200 | 80 |

| SL92 (F92) | Sheet | 8.6 @ 200 | 6 @ 100 | 8.60 @ 200 | 66 |

| SL82 (F82) | Sheet | 7.6 @ 200 | 5.37 @ 100 | 7.60 @ 200 | 52 |

| SL72 (F72) | Sheet | 6.75 @ 200 | 4.77 @ 100 | 6.75 @ 200 | 41 |

| SL62 (F62) | Sheet | 6 @ 200 | 4.77 @ 100 | 6 @ 200 | 33 |

| SL52 (F52) | Sheet | 4.77 @ 200 | 4.77 @ 100 | 4.77 @ 200 | 21 |

BS4483 BRITISH STANDARD

| Ref No. | Std Unit | Longitudinal Wires mm | Cross Wires mm | Pitch of wire | No. of sheet per ton | Mass Kg/m2 |

| A393 | Sheet | 10 | 10 | 200 @ 200 | 15 | 6.16 |

| A252 | Sheet | 8 | 8 | 200 @ 200 | 22 | 3.95 |

| A193 | Sheet | 7 | 7 | 200 @ 200 | 29 | 3.02 |

| A142 | Sheet | 6 | 6 | 200 @ 200 | 40 | 2.22 |

| A98 | Sheet | 5 | 5 | 200 @ 200 | 57 | 1.54 |

Application

1. surface beds (concrete floor slabs on fill) and concrete roads

2. suspended floor slabs, concrete walls, culverts / drains and composite brick / concrete retaining walls

Packaging & Delivery

| Packaging Details: | 1. Around with Angle steel welded into a bundle 2. Use steel bar tied into a bundle 3. 50-100pcs into a bundle |

| Delivery Detail: | 7-15days after received the deposit. |

- Q: How does steel wire mesh perform in load-bearing capacity?

- Steel wire mesh is known for its exceptional load-bearing capacity. The interlocking nature of the wires creates a strong and rigid structure that can withstand heavy loads. The mesh is designed with high tensile strength, enabling it to resist stretching and deformation under pressure. This makes it suitable for a wide range of applications, including construction, fencing, and reinforcement in concrete structures. Additionally, steel wire mesh maintains its load-bearing capacity even in extreme conditions such as high temperatures or corrosive environments. Overall, steel wire mesh is a reliable and durable material that can effectively support heavy loads without compromising its structural integrity.

- Q: Is steel wire mesh suitable for use in sports facilities and stadiums?

- Steel wire mesh is indeed a great choice for sports facilities and stadiums. It offers numerous benefits that make it highly appropriate for such purposes. To begin with, its exceptional strength and durability allow it to endure heavy impacts without any damage or distortion. This makes it perfect for sports facilities where collisions with balls or players are frequent. Moreover, steel wire mesh provides excellent visibility as opposed to solid barriers. It enables spectators to have a clear view of the field or court from any angle, enhancing their overall experience and ensuring a good view for everyone. Furthermore, steel wire mesh exhibits remarkable resistance to weather conditions. It can withstand rain, snow, and extreme temperatures without rusting or deteriorating. This makes it suitable for outdoor sports facilities that are constantly exposed to the elements. Another advantage of steel wire mesh is its low-maintenance nature. It does not require regular painting or refinishing like other materials, reducing the overall cost of upkeep. Additionally, it is easy to clean and prevents the accumulation of dirt or debris, thus providing a clean and safe environment for athletes and spectators. Lastly, steel wire mesh is highly versatile and can be customized to meet the specific requirements of each sports facility or stadium. It can be easily installed in different configurations to cater to the needs of various sports, such as soccer, baseball, or basketball. In conclusion, steel wire mesh is an ideal material for sports facilities and stadiums due to its strength, visibility, weather resistance, low-maintenance, and versatility. It not only offers a secure and durable barrier but also allows spectators to enjoy an unobstructed view of the game.

- Q: What are the different grades of steel used in wire mesh manufacturing?

- There are several grades of steel used in wire mesh manufacturing, including low carbon steel, high carbon steel, stainless steel, and galvanized steel. Each grade has specific properties that make it suitable for different applications and environments.

- Q: How does the temperature resistance affect the performance of steel wire mesh?

- The temperature resistance of steel wire mesh has a significant impact on its performance. Steel wire mesh is commonly used in various applications where it is exposed to different temperature conditions. Firstly, a higher temperature resistance of the steel wire mesh ensures that it can withstand extreme heat without losing its structural integrity. This is particularly important in industrial settings where the wire mesh may be exposed to high temperatures during manufacturing processes or in applications that involve heat transfer. If the wire mesh cannot withstand the temperature, it may deform, lose its shape, or even melt, rendering it useless and compromising the overall performance of the system it is being used in. Secondly, the temperature resistance of steel wire mesh also affects its mechanical properties. Steel wire mesh is often used for its strength and durability, and these properties can be affected by temperature changes. As the temperature increases, the strength of the wire mesh may decrease, leading to reduced load-bearing capacity. This can be critical in applications where the wire mesh is used for structural purposes or in situations where safety is a concern. In extreme cases, the wire mesh may fail completely, resulting in potential accidents or damage to the surrounding infrastructure. Moreover, the temperature resistance of steel wire mesh also influences its corrosion resistance. When exposed to high temperatures, the risk of oxidation and corrosion increases. If the wire mesh is not resistant to such corrosion, it can lead to rusting, weakening the structure and shortening its lifespan. Corrosion can also affect the appearance of the wire mesh, making it less visually appealing or suitable for certain applications. In conclusion, the temperature resistance of steel wire mesh plays a crucial role in determining its performance. A higher temperature resistance ensures that the wire mesh can withstand extreme heat without losing its structural integrity, maintains its mechanical properties, and prevents corrosion. It is essential to consider the temperature requirements of the application when selecting steel wire mesh to ensure optimal performance and longevity.

- Q: Is steel wire mesh suitable for use in HVAC ducts?

- Indeed, steel wire mesh proves to be an appropriate selection for incorporating into HVAC ducts. Displaying robustness and durability, this material can endure the immense pressure and air movement characteristic of HVAC systems. Its outstanding airflow and ventilation capabilities enable the efficient dispersion of heated or cooled air throughout the entire ductwork. Moreover, steel wire mesh exhibits remarkable resistance to corrosion, moisture, and fire, thereby establishing itself as a dependable choice for HVAC ducts. Furthermore, it effectively wards off pests and debris from infiltrating the ducts, ensuring the maintenance of clean and sanitary air circulation. In summary, steel wire mesh emerges as a fitting and pragmatic alternative for utilization in HVAC ducts.

- Q: How is steel wire mesh used in reinforcement of beams?

- To improve the strength and durability of beams, steel wire mesh is commonly utilized for reinforcement. This mesh consists of interconnected steel wires that form a grid-like pattern, which is then embedded within the concrete of the beam. This reinforcement technique, known as wire mesh reinforcement, aids in distributing the load evenly across the beam, thereby reducing the risk of cracking and failure when subjected to heavy loads. The steel wire mesh functions as reinforcement by offering additional tensile strength to the beam. While concrete is strong under compression, it is relatively weak in tension. By introducing the wire mesh, the tensile forces are transferred to the mesh, enabling the concrete to primarily withstand compressive forces. This combination of materials produces a reinforced beam that possesses the capacity to withstand both compression and tension forces, significantly increasing its ability to bear loads. During the construction process, the steel wire mesh is typically strategically positioned within the cross-section of the beam. It is crucial to ensure that the mesh remains at an optimal depth within the concrete to effectively reinforce the beam. This is often accomplished by utilizing supports or chairs to secure the mesh in place during concrete pouring and initial curing stages. In addition to providing strength, steel wire mesh also assists in controlling cracking caused by temperature changes or shrinkage in the concrete. By distributing forces more uniformly, the mesh acts as a barrier, preventing cracks from spreading and reducing their size and extent. This is particularly critical in beams, as cracks have the potential to compromise the structural integrity of the beam and result in failure. In conclusion, steel wire mesh plays a crucial role in enhancing the strength and durability of beams. By offering additional tensile strength, it enables the concrete to resist tension forces and prevents cracking, ultimately ensuring the beam's ability to bear heavy loads and maintain its structural integrity over an extended period.

- Q: What are the benefits of using steel wire mesh in the manufacturing industry?

- Steel wire mesh brings numerous advantages to the manufacturing industry. To begin with, its exceptional strength and durability enable it to bear heavy loads and withstand high temperatures, making it an ideal option for applications that demand a robust material. Its resilience against wear and tear further ensures a longer lifespan compared to alternative materials. Furthermore, steel wire mesh offers remarkable versatility. It can be effortlessly shaped and molded into diverse forms and sizes, making it suitable for a wide array of manufacturing applications. Whether it is employed for filtration, separation, reinforcement, or containment purposes, steel wire mesh can be tailored to meet specific requirements. In addition, steel wire mesh provides excellent visibility and airflow. Its open design permits the passage of light, air, and sound, making it highly desirable for applications that necessitate optimal visibility or ventilation. This attribute proves particularly advantageous in industries such as construction, agriculture, and automotive manufacturing. Moreover, steel wire mesh proves to be cost-effective. Its durability and longevity dramatically reduce the need for frequent replacements, resulting in substantial savings in maintenance and replacement expenses. Additionally, its widespread availability and easy sourcing further contribute to its cost-effectiveness. Furthermore, steel wire mesh exhibits resistance to corrosion. This attribute renders it suitable for applications in harsh environments or industries that handle chemicals or moisture. The corrosion resistance ensures that the mesh retains its structural integrity and functionality over time. Lastly, steel wire mesh promotes environmental friendliness. It is manufactured using recyclable materials, and its prolonged lifespan curbs waste generation. Furthermore, it can be recycled at the end of its useful life, further minimizing its environmental impact. In conclusion, steel wire mesh boasts numerous benefits for the manufacturing industry, including its strength, versatility, visibility and airflow properties, cost-effectiveness, corrosion resistance, and environmental friendliness. These advantages establish steel wire mesh as an outstanding choice for various applications within the manufacturing sector.

- Q: Can steel wire mesh be used for sound insulation?

- Sound insulation can incorporate steel wire mesh as a component, although it is not commonly utilized as the sole material for this purpose. The disruption and absorption of sound waves is facilitated by the presence of steel wire mesh, but it does not possess significant prowess as a standalone sound insulator. For the attainment of efficient sound insulation, steel wire mesh is frequently employed in conjunction with other materials like foam or fiberglass insulation, resulting in a more comprehensive soundproofing system. The mesh serves as a barricade to impede the transmission of sound waves, while the supplementary materials offer absorption and dampening of sound energy. It is important to acknowledge that the effectiveness of steel wire mesh for sound insulation can be influenced by the specific application and the frequency range of the targeted sound. Different materials and configurations may be more suitable for particular situations. In summary, while steel wire mesh can contribute to sound insulation to a certain degree, it is generally employed alongside other materials to yield more effective outcomes.

- Q: Is steel wire mesh suitable for use in mining operations?

- Yes, steel wire mesh is suitable for use in mining operations. It provides strength, durability, and flexibility, making it ideal for various applications such as reinforcing tunnels, supporting roofs, preventing rockfall, and improving overall safety in underground mines.

- Q: Can steel wire mesh be customized to specific requirements?

- Yes, steel wire mesh can be customized to specific requirements. Steel wire mesh is a versatile material that can be tailored to meet various specifications and applications. It can be customized in terms of wire diameter, mesh size, and overall dimensions to fit specific requirements. Different weaving patterns, such as plain, twill, or Dutch weave, can also be used to achieve specific characteristics like strength, flexibility, or filtration capabilities. Additionally, steel wire mesh can be further customized through surface treatments like galvanization or coating to enhance its corrosion resistance or appearance. With these customizable options, steel wire mesh can be adapted to suit a wide range of industries and applications, from construction and infrastructure to industrial processes and filtration systems.

Send your message to us

Concrete Reinforcing Welded Wire Mesh / Trench mesh / steel concrete mesh

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords