Heavy Duty Plastic Mesh Fencing

Heavy Duty Plastic Mesh Fencing Related Searches

Plastic Mesh Deer Fencing Plastic Fence Mesh Steel Mesh Fencing Panels Heavy Duty Plastic Floor Covering Stiff Plastic Mesh Plastic Garden Netting Fencing Pvc Fencing Expanded Plastic Mesh Protective Plastic Sheeting Wrought Iron Fencing Reinforcing Mesh Fine Plastic Mesh Sheet Green Plastic Fencing Roll Mesh Plastic Bags Rigid Plastic Netting Heavy Duty Roofing Felt High Temperature Plastic Mesh Retaining Wall Fine Mesh Wire Large Plastic Panels Plastic Safety Netting Polyester Pleated Mesh Fine Mesh Heavy Duty Mounting Tape Open Weave Plastic Mesh Large Rolls Of Plastic Sheeting Corrigated Plastic Roofing Clear Plastic Netting Heavy Duty Packaging Tape Plastic Mesh BagHeavy Duty Plastic Mesh Fencing Supplier & Manufacturer from China

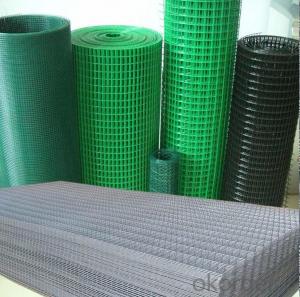

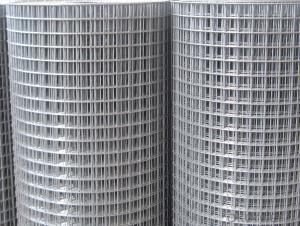

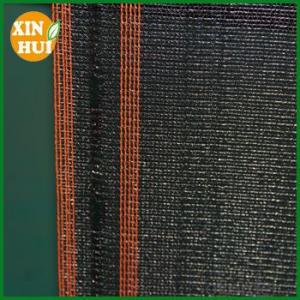

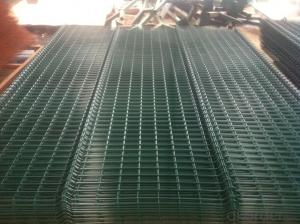

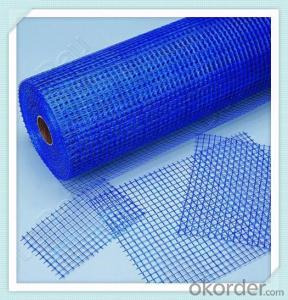

Heavy Duty Plastic Mesh Fencing, also known as plastic mesh or plastic netting, is a durable and versatile product made from high-quality polyethylene. It is designed to provide a strong, long-lasting barrier for various applications, including agricultural, construction, and industrial uses. This type of fencing is characterized by its resistance to UV rays, weather conditions, and physical wear and tear, making it an ideal choice for outdoor environments.The application and usage scenarios for Heavy Duty Plastic Mesh Fencing are extensive. It is commonly used in agriculture to protect crops from birds and other pests, as well as to create secure enclosures for livestock. In construction, it serves as a temporary barrier to keep unauthorized personnel out of hazardous areas, and it can also be used to prevent debris from falling off construction sites. Industrial applications include securing storage areas, creating barriers around machinery, and providing a visual demarcation of restricted zones. Its lightweight and easy-to-install nature makes it a popular choice for a wide range of uses.

Okorder.com is a reputable wholesale supplier of Heavy Duty Plastic Mesh Fencing, offering a large inventory of this product to cater to the diverse needs of customers. With a commitment to quality and customer satisfaction, Okorder.com ensures that the plastic mesh fencing they provide is of the highest standard, meeting the specific requirements of various industries and applications.

Hot Products