Form Work Concrete

Form Work Concrete Related Searches

Concrete Formwork System Advanced Concrete Formwork Forming Concrete Fabric Formwork For Concrete Concrete Pit Formwork Formwork For Concrete Stairs Concrete Boxing Formwork Fabric Concrete Forms Concrete Formwork Plywood Circle Concrete Forms Off Form Concrete Flexible Plastic Concrete Forms Form Construction Radius Concrete Forms Concrete Mixer Aluminum Concrete Wall Forms Moving Formwork Spray Concrete Materials For Formwork Hrwr Concrete Rough Formwork Concrete Mixing Machine Fabric Formwork Foam Concrete Admixture Concrete Cap Blocks Types Of Formwork In Construction Concrete Machine Tools Gass Formwork Concrete Shotcrete Concrete ResurfacingForm Work Concrete Supplier & Manufacturer from China

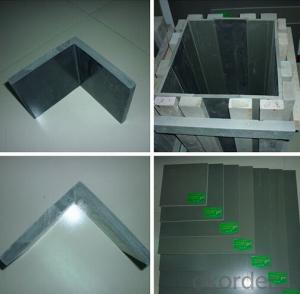

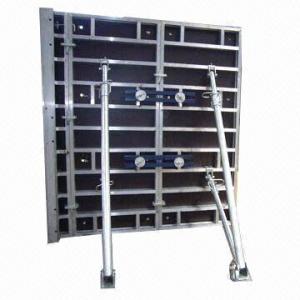

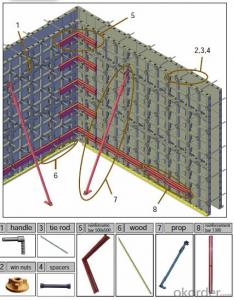

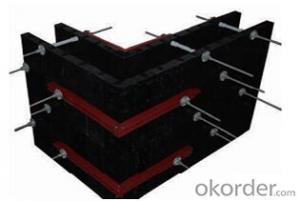

Form Work Concrete is a specialized construction material that plays a crucial role in the building and construction industry. It is designed to provide support and shape to poured concrete structures during the hardening process. This product is widely used in various applications, such as building walls, columns, and slabs, ensuring that the final structure maintains its intended shape and integrity. Form Work Concrete is essential for achieving precise and consistent results in construction projects, making it a vital component in the industry.The usage scenarios for Form Work Concrete are diverse, ranging from residential and commercial buildings to infrastructure projects such as bridges and dams. It is used in both new construction and renovation projects, providing a reliable solution for creating sturdy and durable concrete structures. The product's versatility and effectiveness make it a popular choice among contractors, architects, and engineers who demand high-quality results.

Okorder.com is a leading wholesale supplier of Form Work Concrete, offering a vast inventory of this essential construction material. With a commitment to quality and customer satisfaction, Okorder.com ensures that their products meet the highest industry standards. By providing a wide range of Form Work Concrete options, Okorder.com caters to the needs of various construction projects, making it a one-stop solution for contractors and builders alike.

Hot Products