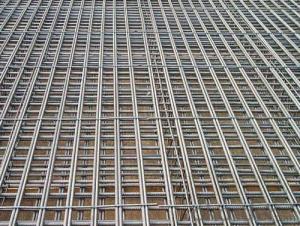

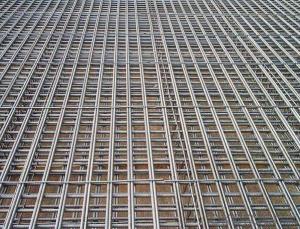

Steel concrete mesh / steel reinforcing welded wire mesh panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Material: steel bar

Weaving: the wires that run parallel to the width of the roll are placed on top of the wires running parallel to the length. Then, the wires are welded where they intersect.

Wire diameter: welded steel bar panels ranges from 5mm to 16mm.

Welded bar panels opening: 75mm to 300mm.

Panel length: 100cm to 1400cm.

Panel width: 100cm to 300cm.

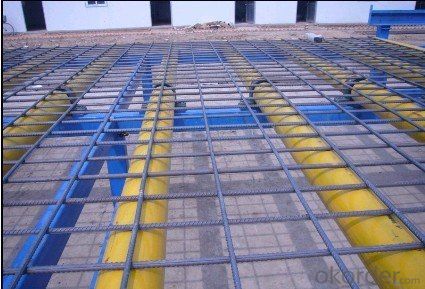

Applications: Welded steel bar panels are widely used in construction reinforcement, the ground for the tunnels, bridges, highway, airport and wharf, also in construction of wall body.

Features: 1.It has a strong and firm body, can bear the high pressure from the concrete and exterior.

The reinforcing mesh can save much man-haur, reduce the material cost in the process.

2.The reinforcing mesh can design by the project requirement, improve the efficiency and

bond to the concrete can meet the special construct needs.

Packing: 1. Around with Angle steel welded into a bundle

2. Use steel bar tied into a bundle

3. 50-100pcs into a bundle

Special packing can be arranged upon request

- Q: How does steel wire mesh perform in thermal conductivity?

- Steel wire mesh has a relatively high thermal conductivity compared to other materials. Due to its metallic properties, steel wire mesh allows heat to be conducted through it easily. This means that when exposed to heat, the steel wire mesh will quickly absorb and transfer the thermal energy. As a result, steel wire mesh can be an efficient conductor of heat, making it suitable for various applications where thermal conductivity is desired, such as in heating and cooling systems, industrial processes, and even in construction for reinforcing concrete structures.

- Q: How is steel wire mesh used in reinforcement of food processing plants?

- Steel wire mesh is commonly used in the reinforcement of food processing plants due to its strength, durability, and hygienic properties. It is primarily used to reinforce the walls, floors, and ceilings of these facilities to ensure they can withstand the rigorous demands of the food processing industry. In food processing plants, steel wire mesh is typically installed in the form of welded or woven wire panels. These panels are made from high-quality stainless steel, which offers excellent resistance to corrosion, chemicals, and extreme temperatures. This makes it an ideal material for maintaining a hygienic environment in food processing facilities. One of the key uses of steel wire mesh in food processing plants is to create partitions or enclosures within the facility. These partitions separate different areas, such as processing, packaging, storage, and administrative spaces, to prevent cross-contamination and maintain strict hygiene standards. Steel wire mesh panels can be easily installed and customized to fit the specific layout and requirements of the facility. Another important application of steel wire mesh is in the construction of shelves, racks, and conveyor systems. These structures are used to store and transport raw materials, finished products, and equipment throughout the facility. Steel wire mesh provides a strong and stable platform for these operations, ensuring the safe and efficient movement of goods. Furthermore, steel wire mesh is often used to reinforce the flooring in food processing plants. The mesh is embedded within the concrete or epoxy resin to enhance its structural integrity and prevent cracking or damage. This is especially crucial in areas where heavy machinery, forklifts, or pallet jacks are used, as it helps distribute the load and prevents the floor from deteriorating over time. Overall, the use of steel wire mesh in the reinforcement of food processing plants is essential for maintaining a clean, safe, and efficient environment. It provides the necessary strength, durability, and hygiene required in these facilities, ensuring compliance with stringent industry regulations and delivering high-quality food products to consumers.

- Q: Is steel wire mesh resistant to fungal or bacterial growth?

- Steel wire mesh exhibits resistance to fungal or bacterial growth due to its inorganic nature, lacking the essential nutrients required for the proliferation of fungi or bacteria. Moreover, the non-porous nature of steel wire mesh impedes the infiltration and establishment of microorganisms. Nevertheless, it is crucial to acknowledge that exposure to moisture or other factors promoting the growth of fungi or bacteria can render the steel wire mesh vulnerable to contamination. Consequently, it is advisable to perform regular cleaning and maintenance to ensure the continued resistance of the steel wire mesh to fungal or bacterial growth.

- Q: Can steel wire mesh be used for waste baskets?

- Yes, steel wire mesh can be used for waste baskets. It is a durable and sturdy material that provides good ventilation and allows for easy visibility of the contents inside the waste basket. Additionally, steel wire mesh is easy to clean and maintain, making it a suitable choice for waste disposal.

- Q: Is steel wire mesh suitable for use in walkways or catwalks?

- Yes, steel wire mesh is suitable for use in walkways or catwalks. It is a strong and durable material that provides excellent support and safety for individuals walking on it. Additionally, the open design of the mesh allows for proper drainage and ventilation, making it ideal for outdoor or industrial applications.

- Q: Can steel wire mesh be used for window screens?

- Indeed, window screens can be fashioned using steel wire mesh. This robust and resilient material effectively safeguards windows from bothersome creatures, pests, and unwanted debris. Not only does it create a robust barricade, but it also permits the passage of refreshing air and ample light. Moreover, steel wire mesh is impervious to rust and corrosion, rendering it a fitting selection for outdoor use. It enhances security and can be effortlessly installed and upheld. Nevertheless, it is crucial to guarantee that the steel wire mesh possesses a sufficiently minuscule aperture size to impede the entry of tiny insects into the abode.

- Q: Can steel wire mesh be used for creating gabion walls?

- Gabion walls can be constructed using steel wire mesh. These walls are built by filling large wire mesh baskets with rocks, stones, or other materials. To ensure durability and longevity, the steel wire mesh used for gabion walls is typically made from high-quality, corrosion-resistant steel. The mesh is tightly woven to create a robust structure that can withstand external pressures. By filling the mesh baskets with rocks or stones, the interlocking mechanism of the mesh securely holds the materials in place, resulting in a stable wall. Steel wire mesh is a popular choice for gabion walls because of its strength, flexibility, and ability to resist erosion and water flow. Additionally, it is cost-effective and relatively easy to install. In summary, steel wire mesh is an excellent option for various landscaping, erosion control, and civil engineering projects as it provides the necessary structural stability and aesthetic appeal required for gabion walls.

- Q: What are the different colors available for steel wire mesh?

- Customers have the option to choose from various colors when it comes to steel wire mesh, depending on their specific requirements and preferences. The most commonly utilized color for steel wire mesh is silver, which is the inherent color of stainless steel. This particular color is often preferred for its sleek and industrial appearance. However, steel wire mesh can also be coated or painted in different colors to enhance its aesthetics or match its surroundings. Coating options such as black, green, and white are popular choices. These colored coatings not only add vibrancy but also offer additional protection against corrosion and UV rays. In essence, the color options for steel wire mesh are extensive, enabling customers to select the most suitable option for their particular application or design.

- Q: How is steel wire mesh used in reinforcement of chemical and petrochemical facilities?

- Steel wire mesh is commonly used in the reinforcement of chemical and petrochemical facilities due to its high strength and corrosion resistance properties. It is primarily used to reinforce concrete structures, such as walls, columns, and foundations, to enhance their durability and structural integrity. The steel wire mesh acts as a reinforcement layer, providing additional strength to the concrete and preventing cracks and failures caused by chemical exposure, temperature fluctuations, and other factors commonly encountered in these facilities. Additionally, the mesh helps to distribute the load evenly across the concrete structure, improving its overall stability and preventing localized failures.

- Q: Can steel wire mesh be used for retaining rock walls?

- Yes, steel wire mesh can be used for retaining rock walls. It provides structural support, prevents erosion, and helps to stabilize the rocks in place.

Send your message to us

Steel concrete mesh / steel reinforcing welded wire mesh panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords