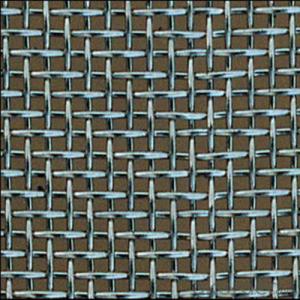

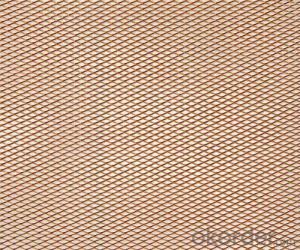

Mineral Screen Crimped Wire Mesh

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mineral Crimped Wire Mesh

Material: stainless steel wire, high tensile steel, high carbon steel, low carbon steel,

Galvanized wire, clooured steel wire.

Crimp Methods: plain weaved, can be crimped(double crimp, intermediate crimp, lock crimp, flat top crimp, lock slot crimp,

Application: it is used extensively in the minerals extraction, food and chemical processing, water and waste treatment, and construction industries, coal industry, decorate area, etc.

Wire diameter: 0.025-16mm

Aperture: 0.025-100 mm

Width: 0.5-4 m

Length: 1-30m

- Q: How is steel wire mesh used in reinforcement of construction projects?

- Steel wire mesh is commonly used in the reinforcement of construction projects to provide additional strength and stability to concrete structures. It is placed within the concrete mixture to act as a support system, preventing cracks and increasing the overall durability of the construction. The mesh helps distribute the load evenly, enhancing the structural integrity of the project and reducing the risk of structural failure.

- Q: Are there any disadvantages of using steel wire mesh?

- There are indeed drawbacks associated with the utilization of steel wire mesh. To begin with, one disadvantage lies in the relatively higher cost of steel wire mesh compared to alternative mesh materials. The inclusion of steel and the manufacturing process contribute to a higher price point for this type of mesh. Consequently, it may not be financially feasible for certain applications or projects with limited budgets. Another drawback pertains to the weight and handling difficulty of steel wire mesh, especially when dealing with large quantities. This can make installation and transportation more challenging, necessitating additional equipment or manpower. If not properly accounted for, the weight of the mesh can also strain supporting structures. Furthermore, steel wire mesh is susceptible to corrosion and rust over time, particularly when exposed to moisture or harsh environmental conditions. This can diminish the mesh's durability and lifespan, requiring more frequent replacements or repairs. Additionally, corrosion can negatively impact the mesh's appearance, resulting in an unsightly or worn-out look. Moreover, steel wire mesh may not be suitable for applications requiring a high level of flexibility or malleability. While known for its strength and rigidity, it may not easily conform to certain shapes or contours, unlike other materials. Consequently, its use may be limited in certain architectural or artistic designs. Lastly, steel wire mesh can conduct electricity, which can be a disadvantage in specific applications. In environments where electrical conductivity poses a concern, additional precautions must be taken to ensure safety and prevent electrical hazards. In conclusion, while steel wire mesh offers numerous advantages such as strength, durability, and security, it is crucial to consider these disadvantages and assess their relevance to the particular application or project at hand.

- Q: Is steel wire mesh resistant to extreme weather conditions?

- Generally speaking, steel wire mesh exhibits resistance to extreme weather conditions. Due to its composition of high-quality steel, it possesses strength and durability. As a result, it can endure harsh environmental elements like heavy rainfall, strong winds, and extreme temperatures. The steel construction of the mesh also guarantees that it will not deform or lose its shape when subjected to pressure. Consequently, it is an optimal material for outdoor applications that face adverse weather conditions. Nevertheless, it is essential to acknowledge that the level of resistance may fluctuate depending on the specific grade and quality of steel employed in the mesh. Moreover, proper installation and maintenance of the mesh are crucial to ensure its long-lasting endurance and ability to withstand extreme weather conditions.

- Q: How does steel wire mesh perform in terms of electromagnetic shielding?

- Electromagnetic shielding is highly effective when using steel wire mesh. The interwoven structure of the wire forms a conductive barrier that effectively blocks or weakens electromagnetic waves. This capability is due to the electrical conductivity of steel, which enables it to redirect and absorb electromagnetic radiation. When electromagnetic waves encounter steel wire mesh, they induce an electric current within the mesh. This occurs because of the steel's conductive properties. The current flows through the wires and generates a magnetic field that opposes the original electromagnetic waves. This process, called reflection and absorption, prevents the waves from passing through the mesh. The effectiveness of steel wire mesh in electromagnetic shielding depends on several factors. These include the thickness and density of the wires, the size of the mesh openings, and the frequency range of the electromagnetic waves. In general, finer and denser mesh structures offer better shielding performance as they can intercept a wider range of frequencies. Steel wire mesh finds widespread use in various applications requiring electromagnetic shielding. These include enclosures for electronic equipment, Faraday cages, radiofrequency shielding, and medical facilities. It effectively prevents electromagnetic interference (EMI) and radiofrequency interference (RFI) from impacting sensitive devices or systems. This ensures their proper functioning and minimizes signal degradation.

- Q: What are the benefits of using steel wire mesh in the chemical recycling industry?

- Steel wire mesh offers several benefits in the chemical recycling industry. Firstly, it provides strength and durability, making it suitable for handling and storing chemicals safely. Additionally, steel wire mesh is resistant to corrosion, ensuring longevity and preventing contamination of the recycled materials. Its open and porous structure allows for efficient airflow and drainage, facilitating the drying process of chemical waste. Moreover, steel wire mesh is easy to clean and maintain, reducing the risk of cross-contamination and ensuring the purity of the recycled products. Overall, the use of steel wire mesh enhances safety, efficiency, and quality in the chemical recycling industry.

- Q: How does the spacing affect the airflow through steel wire mesh?

- The spacing in a steel wire mesh plays a significant role in determining the airflow through it. The spacing, which refers to the distance between adjacent wires, directly affects the open area of the mesh. A smaller spacing means more wires per unit area, resulting in a higher mesh density. This denser mesh restricts the airflow as there are fewer openings for the air to pass through. Consequently, the smaller the spacing, the lower the airflow through the steel wire mesh. On the other hand, a larger spacing increases the open area of the mesh, allowing more air to flow through. With fewer wires per unit area, the air encounters fewer obstacles, resulting in a higher airflow. Therefore, a larger spacing in the steel wire mesh promotes better airflow. It is important to note that while spacing significantly impacts airflow, other factors, such as wire diameter, wire crimping, and mesh thickness, also contribute to the overall airflow characteristics of a steel wire mesh. Additionally, the intended application of the mesh should also be considered, as different industries and situations may require specific airflow requirements.

- Q: Can steel wire mesh be used for retaining walls?

- Yes, steel wire mesh can be used for retaining walls. It is commonly used as reinforcement in retaining walls to provide strength and stability to the structure. The mesh helps to prevent soil erosion and maintain the shape of the wall by holding the backfill in place.

- Q: How does steel wire mesh perform in terms of chemical resistance?

- Steel wire mesh generally has good chemical resistance due to its material composition. It is highly resistant to corrosion, making it suitable for various industrial applications involving exposure to chemicals. However, its performance can vary depending on the specific chemical and concentration. In some cases, certain aggressive chemicals may cause corrosion or degradation of the steel wire mesh over time. Therefore, it is advisable to consider the specific chemical environment and consult with experts or manufacturers for the best-suited steel wire mesh for chemical resistance.

- Q: What is the weight of steel wire mesh?

- The weight of steel wire mesh may differ based on various factors including wire thickness, wire diameter, mesh opening size, and overall panel dimensions. Steel wire mesh is typically available in different gauges, with weights per square foot or square meter corresponding to the gauge. For instance, a light gauge steel wire mesh could weigh approximately 0.5 pounds per square foot (2.45 kilograms per square meter), while a heavy gauge mesh might weigh around 2 pounds per square foot (9.8 kilograms per square meter). It is important to note that these weights are approximate and subject to variation depending on the specific specifications and manufacturing processes of the steel wire mesh.

- Q: Can steel wire mesh be used for bird and animal cages?

- Yes, steel wire mesh can be used for bird and animal cages. It is a durable and strong material that provides security and protection for the animals while allowing for proper ventilation and visibility.

Send your message to us

Mineral Screen Crimped Wire Mesh

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords