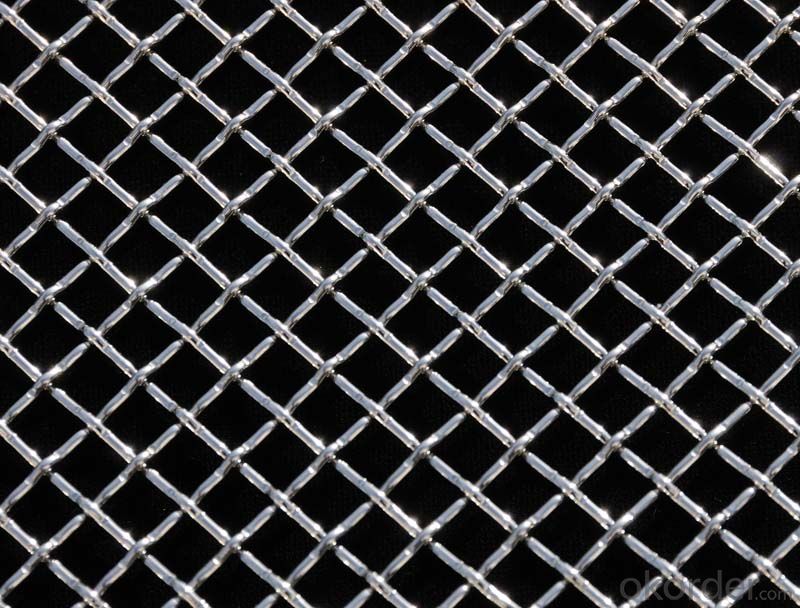

Crimped wire screen for Mine

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

GeneralInformation

GeneralInformation

Type: blank/uncoated, galvanized*, stainless steel, aluminum,copper, brass, plastic-coated

• Width of the grid: 400 – 2.200 mm

• Length of the grid: 300 – 7.000mm, or in roll form up to 50

• Dimensional tolerances in lengthand width: -0 mm /+1 mesh width (customary)

• On request fixed measures withtolerances of +/-2 mm in length and width

Galvanized double intermediate crimp screens aremanufactured from previously galvanized wire. The zinc coating is ca. 7 µm.Galvanized double crimp screens therefore are only limitedly suitable foroutdoor use.

Product Range

Weight of double intermediate crimp screens – in kg/m² | ||||||||||

Mesh width [mm] | Wire diameter [mm] | Crimps* | ||||||||

1,6 | 1,8 | 2,0 | 2,5 | 3,0 | 3,4 | 4,0 | 5,0 | 5,8 | ||

8 x 8 | 3,5 |

|

|

|

|

|

|

|

| 3 |

10 x 10 | 3,0 | 4,2 | 4,5 |

|

|

|

|

|

| 3 |

12 x 12 |

|

| 3,8 |

|

|

|

|

|

| 3 |

15 x 15 |

|

| 3,1 | 4,7 | 6,7 |

|

|

|

| 3 |

20 x 20 |

|

| 2,4 | 3,7 |

|

|

|

|

| 5 |

20 x 20 |

|

|

|

| 5,0 | 6,8 | 9,5 |

|

| 3 |

25 x 25 |

|

|

| 3,1 | 4,3 |

|

|

|

| 5 |

25 x 25 |

|

|

|

|

| 5,5 | 7,7 |

|

| 3 |

30 x 30 |

|

|

| 2,7 |

|

|

|

|

| 7 |

30 x 30 |

|

|

|

| 3,8 | 4,6 |

|

|

| 5 |

30 x 30 |

|

|

|

|

|

| 6,0 | 10,7 |

| 3 |

35 x 35 |

|

|

|

| 2,9 | 4,1 | 5,2 |

|

| 5 |

40 x 40 |

|

|

| 2,4 |

|

|

|

|

| 9 |

40 x 40 |

|

|

|

| 2,8 |

|

|

|

| 7 |

40 x 40 |

|

|

|

|

| 3,5 | 4,7 |

|

| 5 |

40 x 40 |

|

|

|

|

|

|

| 7,3 | 10,2 | 3 |

50 x 50 |

|

|

|

| 2,3 |

|

|

|

| 9 |

50 x 50 |

|

|

|

|

| 2,9 | 3,8 |

|

| 7 |

50 x 50 |

|

|

|

|

|

|

| 5,8 | 8,1 | 5 |

60 x 60 |

|

|

|

|

|

| 3,3 |

|

| 7 |

60 x 60 |

|

|

|

|

|

|

| 5,3 | 6,9 | 5 |

75 x 75 |

|

|

|

|

|

|

| 4,4 | 5,9 | 7 |

100 x 100 |

|

|

|

|

|

|

| 3,5 | 4,5 | 9 |

Application Areas

Our doubleintermediate crimp screens are used in the following fields as:

Safety grids (e.g. car industry,mechanical engineering, building industry)

Filling elements for gates andfences in buildings and gardens

Booth construction

Plant breeding

Pigeon barriers

Noise protection

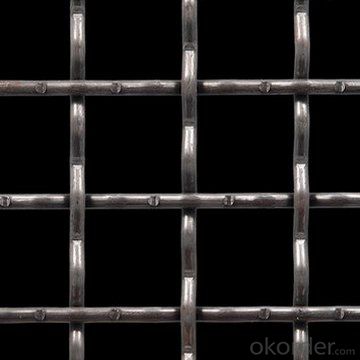

Lock crimp/Lock-Crimp Weave/Scalping Weave

Slotted screens (against flow)

Flat top screens with aone-sided plane surface have their chain and weft wires in plane position atthe intersection points due to the single-sided crimp of the wire. This methodgenerates a grid with a plane, unbroken bottom side.

General Information

Type:blank/uncoated, galvanized*,stainless steel, aluminium, copper, brass.

• Width ofthe grid: up to 2.200 mm

• Length ofthe grid: up to 5.000 mm or in roll form up to 50 m

•Dimensional tolerances in length and width: -0 mm /+1 mesh width (customary)

• Onrequest fixed measures with tolerances of +/-2 mm in length and width

The nominal size of the flat top screen always specifiesthe mesh width (=inner width).

Application Areas

Weight of flat top screens with a one-sided plane surface – in kg/m² | |||||

Mesh width [mm] | Wire diameter [mm] | ||||

2,0 | 2,5 | 3,0 | 4,0 | 5,0 | |

8 x 8 | 5,2 |

|

|

|

|

10 x 10 | 4,3 |

|

|

|

|

12 x 12 | 3,7 |

| 7,7 |

| 18,9 |

13 x 13 |

| 5,2 |

|

|

|

15 x 15 | 3,0 | 4,7 |

|

|

|

16 x 16 |

|

| 6,1 | 11,0 |

|

20 x 20 | 2,3 | 3,5 | 5,0 |

|

|

25 x 25 |

|

| 4,1 | 7,3 |

|

30 x 30 |

| 2,7 | 3,5 | 6,2 |

|

40 x 40 |

|

| 2,7 | 4,5 | 7,5 |

50 x 50 |

|

| 2,4 | 3,6 | 5,8 |

60 x 60 |

|

|

|

| 4,9 |

75 x 75 |

|

|

|

| 4,0 |

Flat topscreens with a one-sided plane surface are used in all fields where constantmesh width and the advantage of a one-sided plane surface are required, e.g.shelves, cage bottoms, support grids for filter fabric, stackable bin walls,security and cover grids. Flat top screens are becoming more and more importantas creative element in the architectural sector (e.g. as cladding for walls andceilings.)

Hook Strips for Screen Sections | ||

|

| Standard Hook Strip, Type 21, for side tensioning |

|

|

|

| Standrad Hook Strip, Type 21, for end tensioning | |

|

|

|

| Double Fold Hook Strip, Type 30, for side tensioning | |

|

|

|

| Double Fold Hook Strip, Type 30, for end tensioning | |

|

|

|

| Welded-on Hook Strip for Screens, for side tensioning | |

|

|

|

| Welded-on Hook Strip for Screens, for end tensioning | |

|

|

|

| Welded-on Hook Strip for P-S-Screen, Type 24, for side tensioning | |

|

|

|

| Welded-on Hook Strip for P-S-Screen, Type 24, for end tensioning | |

|

|

|

| Flat Tensioning Bar, Type 26A, for side tensioning | |

|

|

|

| Flat Tensioning Bar, Type 26A, for side tensioning | |

|

|

|

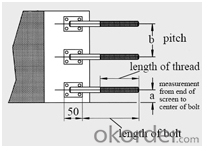

Tensioning Bolts | ||

| Flat Tensioning Bar with tensioning bolts. Please indicate measurements a + b and length of bolt. | |

- Q: What are the different finishing options available for steel wire mesh?

- Steel wire mesh offers several different finishing options, each with its own unique benefits and characteristics. Some of the most commonly used finishing options include: 1. Galvanized: By applying a protective zinc coating to the steel wire mesh, galvanizing prevents corrosion. This option is ideal for outdoor applications or environments with high humidity or moisture, as it provides excellent rust resistance. 2. PVC Coating: Adding a layer of polyvinyl chloride (PVC) to the steel wire mesh not only protects against corrosion but also enhances aesthetics, increases durability, and improves resistance to chemicals and weather conditions. 3. Powder Coating: A popular choice, powder coating involves spraying a dry powder onto the steel wire mesh and then curing it in an oven. This process creates a durable finish that resists chipping, scratching, and fading. It is available in various colors and can provide an attractive appearance. 4. Epoxy Coating: Epoxy coating, a thermosetting polymer coating, offers excellent resistance against corrosion, chemicals, and abrasion. This option is commonly used in industrial settings where durability is crucial. It comes in different colors and thicknesses to meet specific requirements. 5. Stainless Steel: Stainless steel wire mesh is inherently corrosion-resistant, eliminating the need for additional finishing options. It is highly durable and can withstand extreme temperatures, making it suitable for harsh environments and applications where hygiene is important, such as food processing or medical facilities. Each finishing option has its advantages and is suitable for different applications. When selecting a finishing option for steel wire mesh, it is crucial to consider factors such as intended use, environmental conditions, aesthetics, and budget to choose the most appropriate option for your specific needs.

- Q: Can steel wire mesh be used for creating sunscreens or shades?

- Yes, steel wire mesh can be used for creating sunscreens or shades. Steel wire mesh is a durable and versatile material that can effectively block sunlight and provide shade. Its open design allows for airflow and visibility while still providing protection from direct sunlight. Steel wire mesh can be used in various applications such as window screens, pergolas, or outdoor structures to create functional and aesthetically pleasing sunscreens or shades. Additionally, steel wire mesh is resistant to corrosion and is able to withstand harsh weather conditions, making it a suitable choice for outdoor use.

- Q: How is steel wire mesh used in reinforcement of construction projects?

- Due to its strength, durability, and versatility, steel wire mesh is a commonly used material in construction projects for reinforcement purposes. Its primary function is to provide added support and stability to concrete structures. During the pouring process, steel wire mesh is typically placed within the concrete. It acts as a reinforcing material, distributing the load and increasing the overall strength of the structure. This mesh also helps to prevent common issues in concrete such as cracking, shrinkage, and thermal expansion. One of the main advantages of using steel wire mesh for reinforcement is its ability to control and prevent cracks from forming. Acting as a barrier, it limits the size and extent of cracks that may appear, thereby enhancing the stability and integrity of the structure. Additionally, steel wire mesh improves the impact resistance and load-bearing capacity of concrete. It strengthens the structure's tensile strength, enabling it to withstand heavy loads and external forces. This is particularly important in areas prone to high winds, earthquakes, or other natural disasters. Furthermore, steel wire mesh is highly resistant to corrosion, making it suitable for both indoor and outdoor applications. It can withstand exposure to moisture, chemicals, and extreme temperatures without compromising its structural integrity. This ensures the long-lasting durability of the reinforced concrete. Moreover, steel wire mesh is available in various sizes and configurations, allowing for customization to meet the specific requirements of each construction project. Different mesh sizes and wire thicknesses can be selected based on the desired level of reinforcement and the unique needs of the structure. In conclusion, steel wire mesh plays a crucial role in reinforcing construction projects by providing strength, stability, and durability to concrete structures. It reduces the risk of cracking and enhances the load-bearing capacity. Its versatility and resistance to corrosion make it a popular choice for various construction applications.

- Q: How does steel wire mesh perform in vibration resistance?

- Renowned for its exceptional ability to resist vibrations, steel wire mesh is highly regarded for its inherent strength and rigidity. This quality enables it to effectively absorb and disperse the energy produced by vibrations, making it a prime choice for industries that demand optimal vibration resistance. Notably, industrial machinery, automotive components, and structural support systems greatly benefit from the employment of this material. Moreover, the interlocking configuration of the wires within the mesh guarantees stability and prevents excessive movement, thereby amplifying its capacity to resist vibrations. With its unwavering reliability and durability, steel wire mesh proves to be an invaluable solution for mitigating the adverse effects of vibrations across various sectors and applications.

- Q: Can steel wire mesh be used for privacy fencing?

- Yes, steel wire mesh can be used for privacy fencing. While it may not provide as much privacy as solid fences, steel wire mesh with smaller openings can still offer a level of privacy by obstructing the view and preventing direct line of sight. Additionally, the mesh can be combined with other materials such as vinyl or wood to enhance privacy. It is important to ensure that the mesh is of a suitable thickness and height, and that it is properly installed to create a secure and effective privacy fence.

- Q: What are the different roll sizes available for steel wire mesh?

- The roll sizes available for steel wire mesh can vary depending on the specific needs and requirements of the application. Generally, steel wire mesh is available in a variety of roll sizes to accommodate different project sizes and installations. Some common roll sizes for steel wire mesh include 4 feet by 50 feet, 5 feet by 100 feet, 6 feet by 150 feet, and 8 feet by 200 feet. However, it is important to note that these are just some examples and other roll sizes may also be available depending on the manufacturer or supplier. It is recommended to consult with the specific manufacturer or supplier to determine the available roll sizes for steel wire mesh that best suits your project needs.

- Q: Can steel wire mesh be used for privacy partitions?

- Yes, steel wire mesh can be used for privacy partitions. Steel wire mesh is a durable and versatile material that can be used to create visually appealing partitions while still maintaining privacy. It can be installed in various settings such as gardens, outdoor areas, or even indoor spaces. The mesh size and thickness can be chosen to suit the level of privacy required. Additionally, steel wire mesh can be combined with other materials such as wood or glass to create a more aesthetically pleasing and functional privacy partition. Overall, steel wire mesh is a great option for those looking to create privacy partitions that are both durable and stylish.

- Q: How is steel wire mesh used in reinforcement of schools?

- To enhance the structural integrity and ensure safety, schools commonly employ steel wire mesh for reinforcement purposes. This mesh is primarily utilized in concrete applications like floor slabs, walls, and columns. By incorporating the wire mesh into the concrete, it imparts additional strength and prevents cracking or breaking under load. When constructing school buildings, areas that experience higher stress or require added support, such as staircases, balconies, and heavily trafficked zones, typically have steel wire mesh installed. This evenly distributes the load across the structure, thereby minimizing the risk of structural failure. Moreover, steel wire mesh finds application in reinforcing concrete pavements, patios, and outdoor play areas within the school premises. It fortifies these surfaces, making them more durable and resistant to wear and tear, especially in areas where heavy equipment or vehicles may be used. Additionally, steel wire mesh can serve as a substitute for traditional brickwork or masonry when constructing walls. This cost-effective solution offers enhanced flexibility, reduced construction time, and improved earthquake resistance. It proves especially advantageous in regions prone to seismic activity, where ensuring the safety of school buildings is of utmost importance. In summary, the use of steel wire mesh in school reinforcement guarantees robust and long-lasting structures capable of withstanding the demands of daily use. It plays a pivotal role in upholding the safety and structural integrity of school buildings, ensuring a secure environment for students, teachers, and staff.

- Q: How is steel wire mesh used in reinforcement of manufacturing facilities?

- Steel wire mesh is commonly used in the reinforcement of manufacturing facilities for various purposes. One of the primary uses is in concrete reinforcement. Steel wire mesh is embedded within the concrete structure to enhance its structural integrity and increase its load-bearing capacity. This is particularly crucial in manufacturing facilities where heavy machinery and equipment are utilized, as it helps prevent cracking, sagging, and failure of concrete structures. Steel wire mesh is also used in the reinforcement of walls and partitions within manufacturing facilities. It provides added strength and stability, ensuring that the walls can withstand external forces and pressures. This is important in facilities where there are high vibrations or potential impacts, such as from heavy machinery or forklift movements. Moreover, steel wire mesh is used for safety purposes in manufacturing facilities. It can be installed as a protective barrier around hazardous areas or machinery to prevent accidents and injuries. Steel wire mesh acts as a physical barrier, allowing visibility and ventilation while restricting access to dangerous areas. Additionally, steel wire mesh is utilized in the reinforcement of storage racks and shelves within manufacturing facilities. By incorporating wire mesh panels or decking, the structural integrity of these storage systems is improved, allowing for the safe and efficient storage of heavy items and materials. Overall, steel wire mesh is an essential component in the reinforcement of manufacturing facilities. Its versatility, durability, and strength make it an ideal choice for enhancing the structural integrity of concrete, walls, partitions, storage systems, and providing safety measures, ensuring a safe and efficient working environment in manufacturing facilities.

- Q: How is steel wire mesh used in reinforcement of waste treatment facilities?

- Steel wire mesh is commonly used in the reinforcement of waste treatment facilities due to its high tensile strength and durability. It is primarily used to reinforce concrete structures such as walls, floors, and tanks in these facilities. In waste treatment facilities, there are various processes involved such as waste collection, sorting, and treatment. These processes often produce a significant amount of waste material that needs to be stored or contained. Steel wire mesh is used to reinforce the concrete structures that are built to contain and store this waste. The main purpose of using steel wire mesh is to enhance the structural integrity and strength of the concrete. The mesh is typically laid within the concrete mixture during construction, forming a grid-like pattern that adds reinforcement throughout the structure. This helps to distribute and resist the forces and pressures that the waste material may exert on the concrete walls, floors, or tanks. Furthermore, steel wire mesh also helps to prevent cracking and improve the overall durability of the concrete structures. The mesh acts as a reinforcement layer that holds the concrete together, reducing the risk of cracks and ensuring the structure remains intact over time. Additionally, steel wire mesh can be used to reinforce concrete pipes and drainage systems in waste treatment facilities. These pipes and systems are crucial for the efficient management and disposal of waste and wastewater. Reinforcing them with steel wire mesh improves their strength and resistance to external forces, ensuring they can withstand the demands of the waste treatment processes. Overall, steel wire mesh plays a vital role in the reinforcement of waste treatment facilities by enhancing the strength, durability, and structural integrity of the concrete structures. It provides a reliable solution for withstanding the forces and pressures exerted by waste materials and helps ensure the long-term functionality and safety of these facilities.

Send your message to us

Crimped wire screen for Mine

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches