Welded wire mesh-1/4 X 1/4

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Welded Wire Mesh

Welded Wire Mesh is made of by high quality galvanized wire, Low carton steel wire, stainless steel wire, iron wire, Galvanized steel wire, PVC coated iron wire in blue, green, yellow and other colors.

Application of Welded Wire Mesh

Galvanized welded wire mesh, PVC coated welded wire mesh for garden, feeding agriculture, fishing, poultry, mine field, lawn cultivation, and profession’s guard, decorate machine protection. Special welded wire mesh, (Heavy)welded wire mesh panel service as fencing mesh for transportation industry, construction a agriculture.

Surface treatment of of Welded Wire Mesh

a. Black (mild steel wire)

b. Electro galvanized, (galvanized before welding, galvanized after welding)

c. Hot dip galvanized, (galvanized before welding, galvanized after welding)

d. Pvc coated welded wire mesh, (black wire mesh then pvc coated, electro gal. then pvc coated, hot dip gal. the pvc coated)

Advantage of Welded Wire Mesh

Our welded wire mesh has strong corrosion-resisting and oxidation-resisting with good quality and rock bottom price.

Packing of Welded Wire Mesh

1. Waterproof paper then PVC shrinking Film

2. PVC shrinking film only

3. Black waterproof paper only

4. Waterproof paper then metal/wooden pallet

5. Plastic film then carton

(Also as your request. )

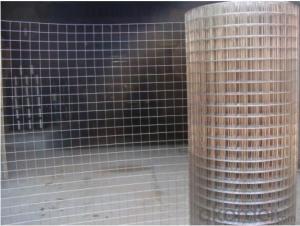

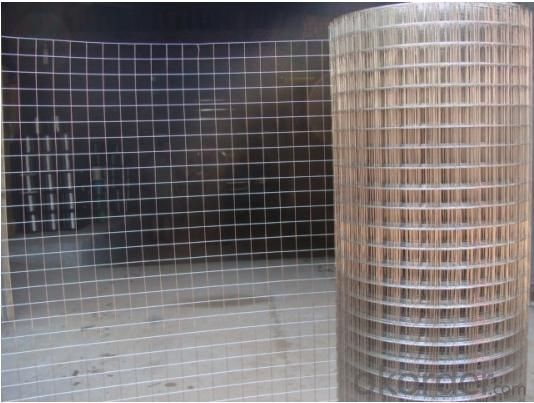

Pictures of Welded Wire Mesh

Specification of Welded Wire Mesh

Standard Welded Wire Mesh (in 30m length, Width of 0.5m-1.8m) | ||

Mesh | Wire Gauge (BWG) | |

Inch | MM | |

1/4" x 1/4" | 6.4mm x 6.4mm | 22-24 |

3/8" x 3/8" | 10.6mm x 10.6mm | 19-22 |

1/2" x 1/2" | 12.7mm x 12.7mm | 16-23 |

5/8" x 5/8" | 16mm x 16mm | 18-21, |

3/4" x 3/4" | 19.1mm x 19.1mm | 16-21 |

1" x 1/2" | 25.4mm x 12.7mm | 16-21 |

1-1/2" x 1-1/2" | 38mm x 38mm | 14-19 |

1" x 2" | 25.4mm x 50.8mm | 14-16 |

2" x 2" | 50.8mm x 50.8mm | 12-16 |

1/4" x 1/4" | 6.4mm x 6.4mm | 12-16 |

Welded Fencing Mesh (in 30m Length, Width of 0.5m -1.8m) | ||

Mesh | Wire Gauge (BWG) | |

Inch | MM | |

2" x 3" | 50mm x 75mm | 1.65-2.5mm |

3" x 3" | 75mm x 756mm | 1.65-2.75mm |

2" x 4" | 50mm x 100mm | 2.1-2.9mm |

4" x 4" | 100mm x 100mm | 2.0mm,2.5mm |

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of welded wire mesh and is one of the large-scale professional investment welded wire mesh bases in China. Annually more than 1000 containers of welded wire mesh are exported to markets in Europe, America and Japan.

2. What is the storage condition?

The welded wire mesh should be stored at room temperature and kept from wet and heat source.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Can steel wire mesh be used for creating reinforcing cages for concrete columns?

- Yes, steel wire mesh can be used for creating reinforcing cages for concrete columns. It provides structural integrity and helps to strengthen the concrete, preventing cracks and enhancing its overall durability.

- Q: Can steel wire mesh be used for creating sculptures or art installations?

- Yes, steel wire mesh can definitely be used for creating sculptures and art installations. Steel wire mesh is a versatile material that offers a range of possibilities for artists and sculptors. Its strength and durability make it suitable for creating large-scale installations, while its malleability allows for intricate and detailed designs. Steel wire mesh can be easily shaped, bent, and welded to create various forms and structures. Artists can use it to build three-dimensional sculptures, create abstract or figurative art, or even construct functional installations like fences or partitions. The open structure of wire mesh also allows for transparency and play with light and shadows, adding an extra dimension to the artwork. Furthermore, steel wire mesh can be painted or coated with different materials to enhance its appearance or protect it from corrosion. This allows artists to experiment with various color schemes and textures to achieve their desired artistic vision. Overall, steel wire mesh offers endless possibilities for creating captivating sculptures and art installations. Its strength, versatility, and aesthetic appeal make it a popular choice among artists looking to push the boundaries of their creativity.

- Q: What are the different wire coatings available for steel wire mesh?

- There are several different wire coatings available for steel wire mesh, including galvanized, PVC coated, epoxy coated, and stainless steel.

- Q: How is steel wire mesh used in reinforcement of paper mills?

- The reinforcement of paper mills heavily relies on steel wire mesh due to its exceptional strength and durability. Throughout the paper manufacturing process, steel wire mesh is predominantly utilized to fortify the screens and filters employed in various production stages. In the formation section of the paper machine, steel wire mesh finds significant application. It acts as a supportive element for the pulp, aiding in the creation of the paper sheet. Its robust and sturdy nature ensures the ability to endure the continuous flow of pulp without sustaining damage, resulting in a consistent and superior paper product. Furthermore, steel wire mesh is also utilized in the dewatering process of paper production. As the paper sheet undergoes the drying stage, the wire mesh screens eliminate excess moisture, facilitating the drying process. The resilient properties of steel wire mesh enable it to withstand the elevated temperatures and pressures involved in this phase, guaranteeing efficient dewatering and preventing any deformities in the paper. Moreover, steel wire mesh finds application in the filtration systems of paper mills. It is commonly employed as a reinforcement material in various filters and screens that eliminate impurities and contaminants from the pulp or wastewater. The fine openings in the wire mesh allow for effective filtration while maintaining a high flow rate. All in all, steel wire mesh plays a vital role in reinforcing paper mills by providing strength, stability, and durability to the screens, filters, and other equipment used in the paper manufacturing process. Its utilization ensures the smooth operation of the mills, enhances the quality of the final paper product, and improves the overall efficiency of the paper production process.

- Q: Can steel wire mesh be used for speaker cabinets?

- Yes, steel wire mesh can be used for speaker cabinets. Steel wire mesh is a versatile material that offers several benefits when used in speaker cabinets. It provides a protective barrier that prevents foreign objects from entering the cabinet and damaging the speaker components. Additionally, it allows sound to pass through easily, ensuring optimal audio performance. Steel wire mesh is also durable and long-lasting, making it a suitable choice for speaker cabinets that need to withstand regular use and potential impacts. Ultimately, the use of steel wire mesh in speaker cabinets can enhance both the functionality and aesthetics of the speakers.

- Q: Is steel wire mesh suitable for outdoor furniture?

- Outdoor furniture can indeed benefit from the use of steel wire mesh. Renowned for its strength and durability, steel wire mesh proves to be an outstanding choice for outdoor purposes. It boasts resistance against rust, corrosion, and fading, which is particularly essential for furniture that faces exposure to outdoor elements like rain, sunlight, and temperature fluctuations. Moreover, the versatility of steel wire mesh allows it to be shaped and molded into various designs, enabling the creation of imaginative and distinctive outdoor furniture pieces. Furthermore, its open and breathable nature enhances airflow, ensuring comfortable seating even during scorching weather. In conclusion, steel wire mesh presents itself as a practical and dependable option for outdoor furniture, offering a combination of durability, weather resistance, and aesthetic appeal.

- Q: Is steel wire mesh suitable for use in marine environments?

- Yes, steel wire mesh is suitable for use in marine environments. Steel wire mesh is known for its strength, durability, and corrosion resistance, making it an ideal material for marine applications. The steel wire used in the mesh is typically treated with a protective coating, such as galvanization or PVC coating, to enhance its resistance to corrosion caused by saltwater and other harsh marine conditions. Additionally, steel wire mesh has a high load-bearing capacity and can withstand the forces of waves, currents, and marine life. It is commonly used in marine applications such as boat and dock construction, fish farming, and coastal protection structures. Overall, steel wire mesh is a reliable and cost-effective choice for marine environments due to its ability to withstand the challenging conditions found in these settings.

- Q: What are the advantages of using steel wire mesh in construction?

- There are several advantages of using steel wire mesh in construction. Firstly, steel wire mesh provides high tensile strength and durability, making it suitable for reinforcing concrete structures and enhancing their structural integrity. Additionally, steel wire mesh offers excellent resistance to corrosion, ensuring the longevity of the construction project. It also provides a cost-effective solution due to its ease of installation and low maintenance requirements. Moreover, steel wire mesh allows for better load distribution and reduces cracking in concrete, resulting in improved overall performance. Lastly, steel wire mesh is highly versatile, allowing it to be customized to fit various construction needs, such as reinforcing walls, slabs, and foundations.

- Q: Steel skeleton plastic pipe and steel mesh skeleton plastic pipe is the difference between what

- Steel wire mesh is calculated inside the brick wall, directly advise the total length of the outer wall of the outer wall wire + the total length of the inner wall of the outer wall + the total length of the steel mesh on both sides of the interior wall.

- Q: Can steel wire mesh be used for gabion planters?

- Yes, steel wire mesh can be used for gabion planters. Gabion planters are essentially wire mesh containers filled with stones or other materials, which can be used for planting various types of vegetation. Steel wire mesh is commonly used for constructing gabion planters due to its durability and strength. It provides a sturdy framework that holds the stones in place while allowing water to drain through. Additionally, steel wire mesh is resistant to corrosion, making it suitable for outdoor use. Overall, steel wire mesh is a reliable and practical choice for constructing gabion planters.

Send your message to us

Welded wire mesh-1/4 X 1/4

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords