1/4 Inch Aluminum Plate

1/4 Inch Aluminum Plate Related Searches

1/4 Aluminum Plate 1/4in Aluminum Plate 1/4 Inch Thick Aluminum Plate Aluminum 1/4 Plate 1/4 Plate Aluminum Aluminum Plate 1/4 1/4 Thick Aluminum Plate 1/4 In Aluminum Plate Aluminum Plate 1/4 Inch Thick Aluminum Plate 1/4 Thick 3/4 Inch Aluminum Plate 1/4 Inch Diamond Plate Aluminum 1/4 Inch Aluminum Diamond Plate 1 4 Inch Aluminum Plate 1/4 Diamond Plate Aluminum 3/4 Inch Thick Aluminum Plate 3/4 Thick Aluminum Plate 3/4 Aluminum Plate 1/4 Inch Aluminum Plate 4x8 1/4 Aluminum Diamond Plate 1/4 Aluminum Plate For Sale 1 4 Aluminum Plate 1 4 Inch Thick Aluminum Plate 4' X 8' X 1/4 Aluminum Plate 4 Inch Aluminum Plate 1/4 Inch Aluminum Plate Near Me 1/2 Inch Aluminum Plate Aluminum Diamond Plate 1/4 Thick 1/4 Inch Aluminum Plate Strength Bending 1/4 Aluminum Plate1/4 Inch Aluminum Plate Supplier & Manufacturer from China

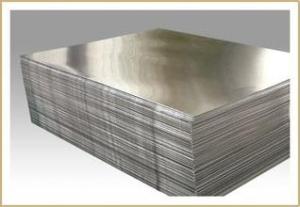

1/4 Inch Aluminum Plate is a versatile metal product known for its strength, lightweight, and corrosion resistance. It is widely used in various industries, including construction, automotive, aerospace, and manufacturing. This product offers numerous advantages such as durability, ease of fabrication, and excellent thermal conductivity, making it a popular choice for numerous applications.The 1/4 Inch Aluminum Plate is employed in a variety of usage scenarios, such as in the fabrication of structural components, vehicle parts, and various industrial equipment. Its ability to withstand high temperatures and resist corrosion makes it ideal for both indoor and outdoor applications. Additionally, its lightweight nature contributes to energy efficiency and reduced material costs in various projects.

Okorder.com is a reputable wholesale supplier of 1/4 Inch Aluminum Plate, boasting a large inventory to cater to the diverse needs of clients. The company prides itself on providing high-quality products at competitive prices, ensuring that customers receive the best value for their investment. By partnering with Okorder.com, customers can expect prompt delivery, excellent customer service, and a wide range of 1/4 Inch Aluminum Plate options to choose from.

Hot Products