3003 H14 H24 Aluminum Strip for Hollow Glass Strip Factory Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

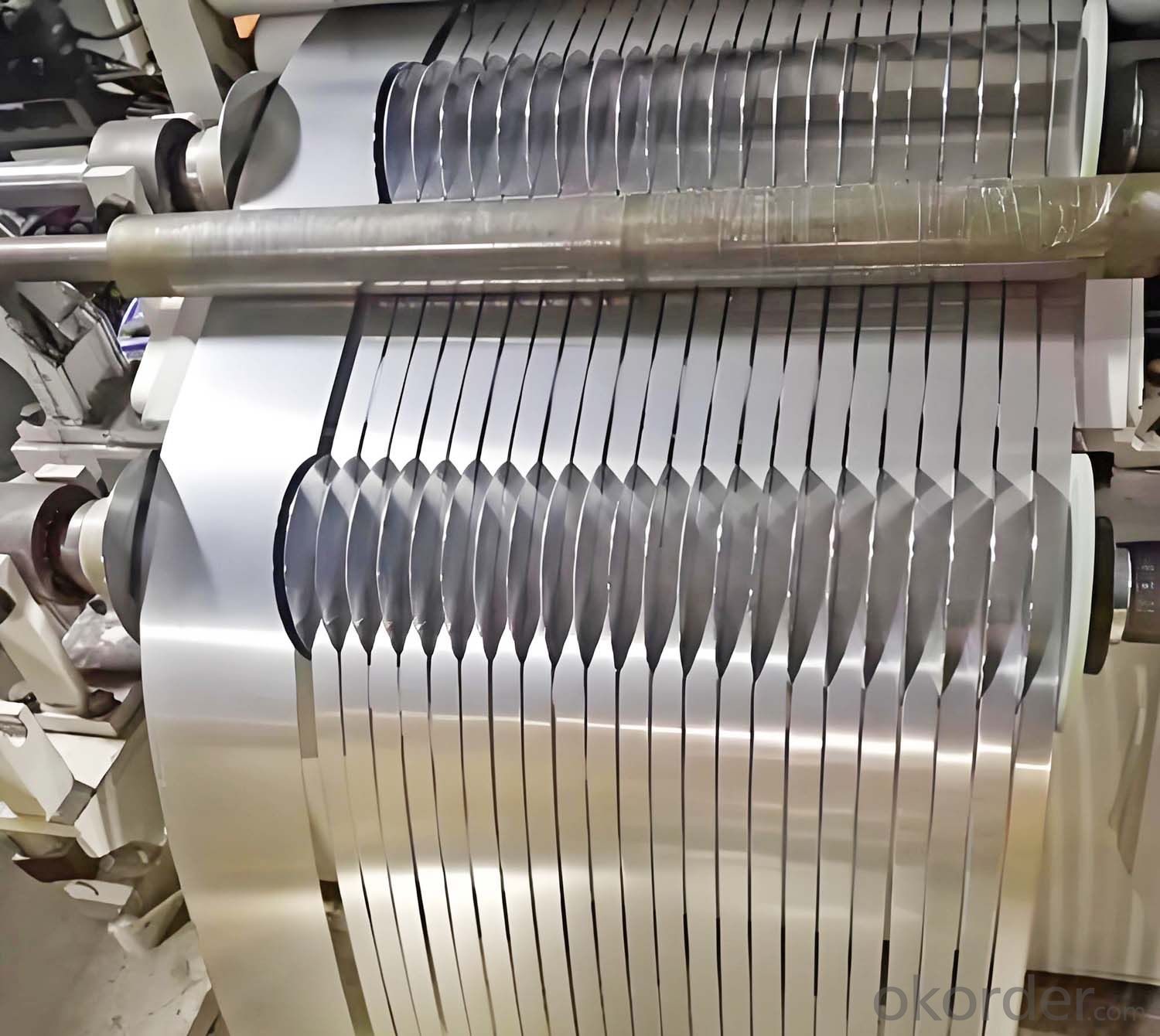

Specification

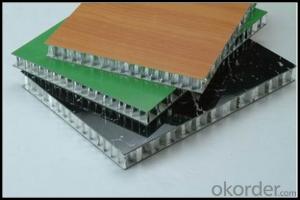

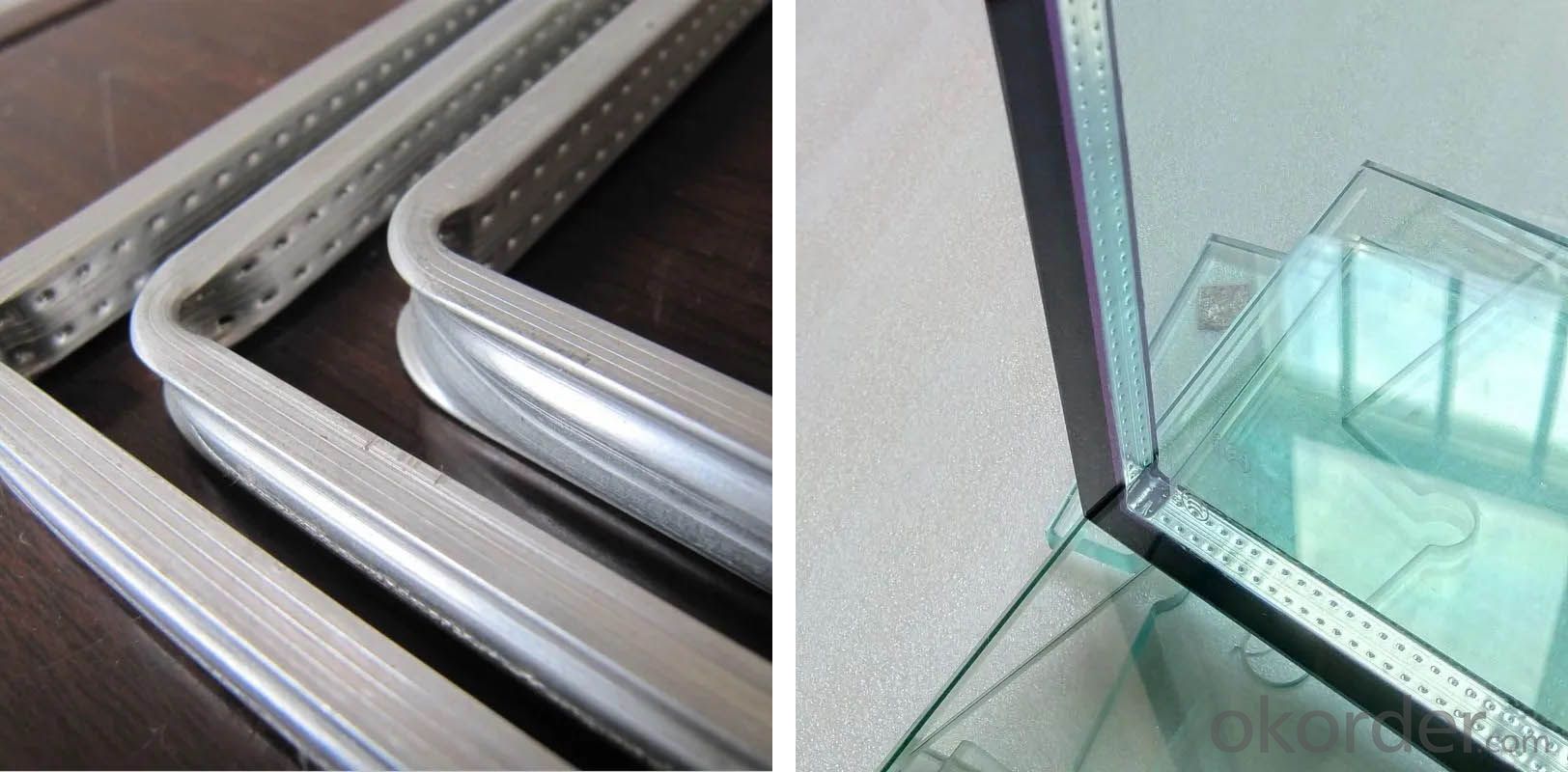

Hollow glass aluminum strip is used for hollow glass strip spacers. The commonly used material is 3003 aluminum alloy. Its quality is directly related to the use effect, service life and thermal insulation function of hollow glass. Its main function is to evenly separate the two sides or multiple pieces of glass in the hollow glass and effectively support it.

Hollow glass strips are aluminum products made of high-purity aluminum as raw materials. After dozens of process treatments, the surface is flat and smooth, non-oxidizing, non-corrosive, and has no effect on desiccant. It effectively eliminates the phenomenon of atomization. It is a new type of environmentally friendly building material product with a broad application market. The surface of 3003 alloy aluminum strip is flat and smooth, rust-proof, and corrosion-resistant with high brightness; the surface of the aluminum strip is evenly permeable, with good straightness, no deformation, and stable size; it has high strength and good toughness, and can be continuously bent into aluminum frames of any angle with bending equipment.

Advantages of 3003 aluminum strip for hollow glass strips:

1. Excellent corrosion resistance: stable performance in humid environment, not easy to rust.

2. Good processing performance: easy to process and shape, maintain strength and toughness, not easy to crack.

3. Lightweight characteristics: reduce the weight of finished glass, reduce transportation and installation costs.

4. Good thermal conductivity: improve thermal insulation performance and enhance energy saving effect.

5. Strong antioxidant performance: maintain long-term beauty and functionality.

6. Strong adaptability to surface treatment: various surface treatments can be performed to improve corrosion resistance and aesthetics.

7. High cost performance: low cost, superior performance, an economical choice.

8. Environmental protection and recyclable: aluminum can be fully recycled, in line with the concept of green building and sustainable development.

Specifications:

| Alloy | 3003 |

| Temper | H14 H24 H16 etc |

| Thickness | 0.25-0.4mm |

| Diameter | 100-260mm |

| Surface treatment | painting, anodizing |

| Technology | cold rolling |

| Color | silver, black |

| Application | hollow glass, hollow door, train, bus |

| Features |

|

| MOQ | 1-3 tons |

3003 aluminum alloy chemical composition (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | 0.1 | - | 0.05 | 0.15 | remainder |

Application fields

1. Hollow glass strips: widely used in building doors and windows, glass curtain walls, energy-saving glass and other structures.

2. Other related fields: in some cases, it can also be used for insulation and sealing components that require lightweight and corrosion-resistant materials.

FAQ:

Q1: How to ensure quality?

A1: Factory test certification is provided with shipment, and third-party inspection can be provided

Q2. What are the main products of your company?

A2: Our main products are aluminum, aluminum plate, aluminum foil, aluminum strip, patterned plate, automotive plate, marine grade aluminum plate, household foil, hydrophilic aluminum foil, bottle cap material, etc.

Q3: Where is your factory?

A3: Our company's processing center is located in Xin'an Industrial Assemble Region, Luoyang, Henan Province, China

Q4: What are the advantages of your company?

A4: We have many professionals, technicians, more competitive prices and best after-sales service than other companies.

- Q: What are the elements and compounds that make up aluminum strips?

- <p>Aluminum strips are primarily composed of the element aluminum (Al), which is a lightweight, silvery-white, and malleable metal. Aluminum is a pure element and not a compound, so its composition is straightforward. It is found in Group 13 of the periodic table and has an atomic number of 13. In its pure form, aluminum is soft and lacks sufficient strength for many applications, so it is often alloyed with other elements such as copper, magnesium, manganese, silicon, and zinc to improve its strength and durability. These alloying elements can make up a small percentage of the total composition, but they significantly enhance the properties of the aluminum strips for various industrial uses.</p>

- Q: What types of aluminum strips are more appropriate for industrial purposes?

- <p>Yes, there are specific types of aluminum strips that are more suitable for industrial applications. These include 1100 series aluminum strips, known for their high purity and excellent corrosion resistance. 3003 series strips are also popular for their good formability and weldability, making them ideal for applications like chemical equipment and aircraft parts. Additionally, 5052 series strips are valued for their strength and resistance to marine environments, often used in shipbuilding and offshore structures. Each type is chosen based on the specific needs of the industrial application, such as strength, malleability, and environmental resistance.</p>

- Q: The question asks if it's possible to use aluminum strips for insulating the exterior walls of a building.

- <p>Yes, aluminum strips can be used for exterior wall insulation, but they are typically used as a vapor barrier or as part of a metal stud framing system rather than as an insulating material themselves. Aluminum is a good conductor of heat, so it's not an insulator. Instead, it's often used to create a barrier against moisture and air infiltration. For insulation, materials like fiberglass, cellulose, or foam are more appropriate. Aluminum strips can help secure insulation boards in place and provide a base for attaching exterior finishes.</p>

- Q: What benefits does aluminum provide compared to other metals when used for roofing applications?

- <p>Aluminum offers several advantages for roofing, including its lightweight nature, which reduces structural load. It is highly resistant to corrosion, making it suitable for various climates and environments. Aluminum's malleability allows for easy shaping and forming, enabling complex designs. It also has excellent reflectivity, which can help in reducing heat absorption and improving energy efficiency. Additionally, aluminum is recyclable and has a lower environmental impact compared to some other metals. These properties make aluminum a popular choice for roofing materials.</p>

- Q: This question asks for the most suitable type of aluminum strip for outdoor applications.

- <p>The best type of aluminum strip for exterior use is typically 3003-H14 alloy. This alloy is known for its excellent corrosion resistance, which is crucial for outdoor applications where the strip may be exposed to various weather conditions. It also offers good formability, making it easy to shape and bend for various construction and architectural purposes. Additionally, 3003-H14 aluminum strip has good weldability, which is beneficial for applications where joining is required. It is commonly used for roofing, siding, and other exterior applications due to its durability and weather-resistant properties.</p>

- Q: Is it possible to use aluminum strips as materials for roofing membranes?

- <p>Yes, aluminum strips can be used for roofing membranes. They are known for their durability, corrosion resistance, and lightweight properties, making them suitable for various roofing applications. Aluminum strips can be used in the form of standing seam metal roofs, which are popular for their sleek appearance and strength. They are also low maintenance and can be recycled, contributing to their environmental sustainability. However, it's important to ensure proper installation and sealing to prevent leaks and maintain the integrity of the roof.</p>

- Q: What's the specialty of aluminum strip rolling?

- Now, metal pressure processing profession, undergraduate course is called material forming and control major, master and doctor stage is called material processing engineering.

- Q: What precautions should be taken while handling aluminum strips to ensure safety?

- <p>When using aluminum strips, it's important to follow safety measures to prevent injury or damage. Always wear protective gloves and eyewear to protect against sharp edges and flying debris. Ensure good ventilation to avoid inhaling aluminum dust, which can be harmful. Avoid using aluminum strips near open flames or high heat sources as aluminum can melt and cause burns. Keep aluminum strips away from corrosive chemicals that can react with it. Store aluminum strips properly to prevent damage and ensure they are dry to avoid rusting. Always follow the manufacturer's guidelines for safe handling and usage.</p>

- Q: Is it possible to substitute aluminum strips with other metal sheets in construction projects?

- <p>Yes, you can use different types of metal sheets in place of aluminum strips in your construction projects, depending on the specific requirements. Metals like steel, stainless steel, and copper can be used as alternatives. Each metal has unique properties such as strength, weight, corrosion resistance, and thermal conductivity, which can affect the project's performance and longevity. It's crucial to consider the environmental conditions, load-bearing requirements, and cost implications when choosing an alternative to aluminum. Always consult with a structural engineer or a material expert to ensure the chosen metal meets the project's needs.</p>

- Q: Which brand of aluminium band for dry transformer?

- Personal feeling 1070 should be better, because a higher proportion of content, electrical conductivity must be better, but at present, the market is indeed everyone's use.

Send your message to us

3003 H14 H24 Aluminum Strip for Hollow Glass Strip Factory Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Related keywords