1/4 Inch Aluminum Plate 4x8

1/4 Inch Aluminum Plate 4x8 Related Searches

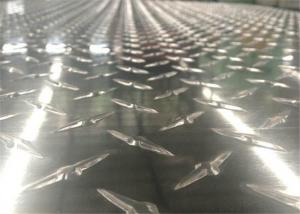

1/4 Aluminum Plate 4x8 1 4 Aluminum Plate 4x8 Aluminum Plate 4x8 1/4 Aluminum Diamond Plate 4x8 1/2 Aluminum Plate 4x8 4x8 Aluminum Plate 4' X 8' X 1/4 Aluminum Plate 4x8 1/4 Diamond Plate Aluminum 4x8 1/4 Aluminum Diamond Plate 3/8 Aluminum Plate 4x8 4 X 8 X 1 4 Aluminum Plate 1/4 Inch Aluminum Plate 4x8 1/8 Diamond Plate Aluminum 3/16 Aluminum Plate 4x8 4x8 1/8 Aluminum Diamond Plate 4x8 Aluminum Diamond Plate 1/8 1/8 Aluminum Diamond Plate 4'X8' 1/4in Aluminum Plate 1/4 Inch Thick Aluminum Plate 4x8 1 4 Aluminum Diamond Plate 1/4 Plate Aluminum 4 Inch Aluminum Plate 1/4 Aluminum Plate 4x8 1 8 Aluminum Diamond Plate Aluminum 1/4 Plate 4 X 4 Aluminum Plate 1/8 Inch Aluminum Plate Aluminum Diamond Plate 4x8 1 4 Inch Aluminum Plate 1/4 Thick Aluminum Plate1/4 Inch Aluminum Plate 4x8 Supplier & Manufacturer from China

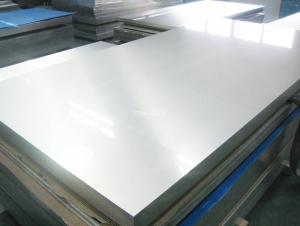

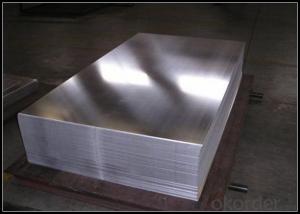

The 1/4 Inch Aluminum Plate 4x8 is a versatile product that consists of aluminum sheets with a thickness of 1/4 inch and dimensions of 4 feet by 8 feet. These plates are known for their durability, corrosion resistance, and lightweight properties, making them an ideal choice for various applications. The 1/4 Inch Aluminum Plate 4x8 is widely used in industries such as construction, manufacturing, and automotive, where it serves various purposes like structural support, heat exchangers, and decorative panels. Its strength and flexibility make it a popular choice for both commercial and residential projects.The 1/4 Inch Aluminum Plate 4x8 is also favored for its ease of fabrication and ability to be cut, bent, and welded into various shapes and forms. This adaptability allows for the creation of custom designs and structures, catering to the specific needs of different projects. Whether it's used for creating intricate architectural features or providing a sturdy base for industrial machinery, this product offers a reliable and efficient solution. Its non-magnetic and non-sparking nature also makes it suitable for environments where safety is a priority.

Okorder.com is a leading wholesale supplier of the 1/4 Inch Aluminum Plate 4x8, offering a vast inventory to cater to the diverse needs of customers. With a commitment to quality and customer satisfaction, Okorder.com ensures that each 1/4 Inch Aluminum Plate 4x8 meets the highest industry standards. By maintaining a large stock, Okorder.com is able to provide quick and efficient delivery, ensuring that customers have access to the materials they need when they need them. This makes Okorder.com the go-to destination for those seeking a reliable source for 1/4 Inch Aluminum Plate 4x8.

Hot Products