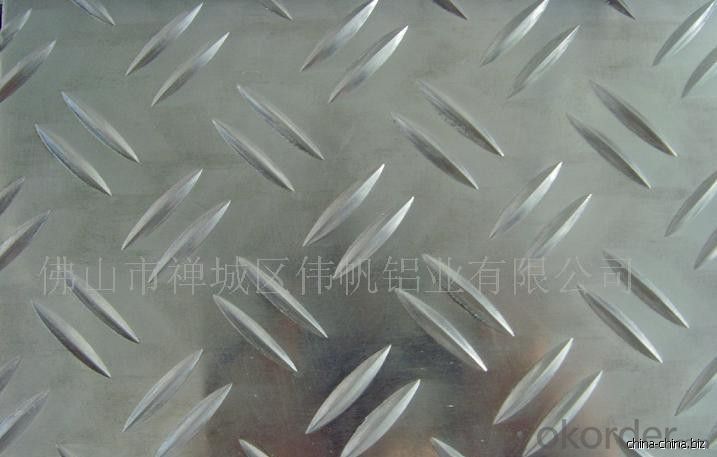

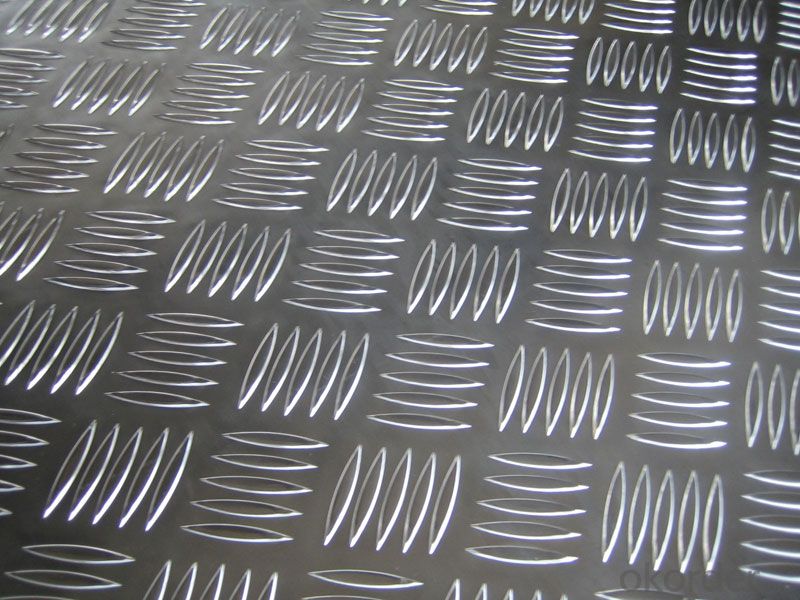

4x8 Embossed Aluminum Tread Plate Sheets for Bus Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications:

aluminum tread plate

1.Usage: using in bus, cars and shipping vessel as the floor.

2. Alloy: AA1050, AA1060, AA1070, AA3003

aluminum tread plate

1.Features:

1) Alloy: AA1050, AA1060, AA1070, AA3003

2) Temper: H14, H16, H18, H24, H26, H28, H34, H36, H38

3) Thickness: 1.20mm - 5.00mm

4) Width: 1000 ~ 1250mm

5) Length of sheet: 1000mm ~ 4000mm

2.Packing:

Covering with plastic film and brown paper and then packed with wooden package, directly loading into container for transshipment.

- Q: Are aluminum sheets suitable for electrical busbars?

- Electrical busbars can indeed be made from aluminum sheets. Aluminum is extensively used in the electrical industry due to its exceptional electrical conductivity, lightweight properties, and affordability in comparison to metals like copper. Aluminum sheets can be easily shaped and sized to fit the required dimensions for busbars, making them a versatile choice for electrical applications. Moreover, aluminum possesses commendable thermal conductivity, aiding in the dissipation of heat generated during electrical operations. However, it is crucial to acknowledge that aluminum has a lower electrical conductivity than copper, necessitating larger cross-sectional areas to achieve equivalent electrical performance. Consequently, it is vital to consider the specific requirements of the electrical system and seek expert advice to determine the suitability of aluminum sheets for a particular busbar application.

- Q: How do you join aluminum sheets together?

- One common method to join aluminum sheets together is through welding. This involves melting the aluminum at the joint and then allowing it to solidify, creating a strong bond. Other methods include using adhesive bonding, riveting, or using mechanical fasteners such as screws or bolts. The choice of joining method depends on factors such as the application, the thickness of the aluminum sheets, and the desired strength and appearance of the joint.

- Q: What are the different methods of joining aluminum sheets without welding?

- There are several methods of joining aluminum sheets without welding, including adhesive bonding, mechanical fastening (such as screws or rivets), clinching, and using non-welding techniques like friction stir welding or laser welding.

- Q: Can aluminum sheet be used for food packaging?

- Food packaging can utilize aluminum sheet, which is a popular choice due to its unique properties. This material is lightweight, flexible, and provides excellent protection against moisture, oxygen, and light. Consequently, it helps extend the shelf life of products and maintains their freshness. Aluminum sheet is commonly employed to package beverages, snacks, dairy products, and ready-to-eat meals. Furthermore, it is non-toxic and does not react with food, ensuring safety when in direct contact with consumables. Its versatility allows for easy customization to meet various packaging requirements. Overall, aluminum sheet is widely trusted and used for food packaging due to its durability, protective properties, and adherence to safety standards.

- Q: How do aluminum sheets compare to steel sheets in terms of weight?

- Aluminum sheets, when compared to steel sheets, are significantly lighter in weight. This is because aluminum has a lower density than steel, making it a more lightweight and versatile material. The specific weight difference between aluminum and steel sheets will depend on the thickness and dimensions of the sheets. However, generally speaking, aluminum sheets can weigh about 1/3 less than steel sheets of the same size. This makes aluminum sheets an ideal choice in applications where weight is a critical factor, such as in the aerospace industry or for lightweight structures.

- Q: Can aluminum sheet be used for heat exchangers?

- Indeed, aluminum sheet can be effectively utilized in heat exchangers. The utilization of aluminum as a material for heat exchangers is widespread owing to its remarkable thermal conductivity, lightweight nature, and resistance to corrosion. The remarkable thermal conductivity of aluminum facilitates the efficient transfer of heat between fluids, rendering it suitable for a multitude of heat exchange applications. Furthermore, aluminum is obtainable in diverse alloys and thicknesses, granting adaptability in design and customization to cater to specific heat exchanger prerequisites. On the whole, aluminum sheet emerges as a favored option for heat exchangers in industries encompassing automotive, HVAC, and aerospace.

- Q: Are aluminum sheets suitable for automotive body reinforcements?

- Yes, aluminum sheets are suitable for automotive body reinforcements. Aluminum is lightweight yet strong, making it an ideal material for reinforcing automotive bodies. It offers several advantages such as improved fuel efficiency, increased load-bearing capacity, and enhanced safety. Additionally, aluminum is resistant to corrosion, which ensures the longevity of automotive body reinforcements.

- Q: Are aluminum sheets easy to clean?

- Yes, aluminum sheets are generally easy to clean due to their smooth surface and non-porous nature, allowing for easy removal of dirt, grease, and stains with regular cleaning agents.

- Q: This question asks about the typical duration an aluminum roof sheet can last before it needs to be replaced or repaired.

- <p>The lifespan of aluminum sheets for roofing can vary depending on the quality of the material, installation, and environmental factors. On average, a well-maintained aluminum roof can last between 20 to 50 years. High-quality aluminum roofing materials, when properly installed, can even exceed this range, offering a lifespan of up to 70 years. However, it's important to note that regular inspections and maintenance are crucial to extend the life of any roofing material, including aluminum.</p>

- Q: Can aluminum sheets be used for electronic devices?

- Yes, aluminum sheets can be used for electronic devices. Aluminum is widely used in the electronics industry due to its excellent conductivity, lightweight nature, and thermal management properties. It is commonly used as a base material for printed circuit boards (PCBs), heat sinks, enclosures, and other components in electronic devices.

Send your message to us

4x8 Embossed Aluminum Tread Plate Sheets for Bus Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords