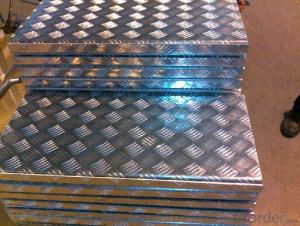

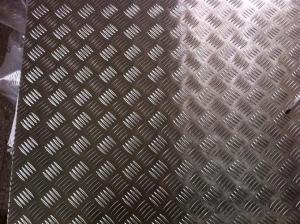

4x8 Aluminum Tread Plate

4x8 Aluminum Tread Plate Related Searches

Led Light Bulbs For Ceiling Fixtures Led Lamps For Ceiling 42 In Ceiling Fan With Light Aluminum Coil Stock For Gutters Aluminum Foil For The Grill Hole Saw For Aluminum Plate Aluminum Tread Plate For Trailer Bow Plate For Aluminum Boat Aluminum Foil For Grow Room Aluminum Foil For Joint PainHot Searches

Stock Price For Aluminum Aluminum Coil Stock For Sale Aluminum Gutter Coil For Sale Used Aluminum Scaffolding For Sale 1/4 Aluminum Plate For Sale Aluminum Bar Stock For Sale Aluminum Round Stock For Sale Aluminum Diamond Plate For Sale Aluminum Scaffolding For Sale Craigslist 6061 Aluminum Plate For Sale Aluminum Dock Plate For Sale 7075 Aluminum Plate For Sale Aluminum Tread Plate For Sale Aluminum Checker Plate For Sale Aluminum Plate For Sale Near Me Plate Aluminum For Sale Aluminum Plate For Sale Aluminum Square Stock For Sale Aluminum Flat Stock For Sale Billet Aluminum Stock For Sale4x8 Aluminum Tread Plate Supplier & Manufacturer from China

Okorder.com is a professional 4x8 Aluminum Tread Plate supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest 4x8 Aluminum Tread Plate firm in China.Hot Products

FAQ

- are there any carbonated mineral water that are produced in aluminium cans.

- fee, and make contact with. they are the two carbonated interior the comparable way. that is basically a sensible (no longer in my opinion) advertising ploy. A play on words suggesting that one is larger than the different!

- the amp setting when welding aluminum tig? and what color should the electrode feeder be bronze or chrome grey? u know the one u use with your hands

- Best electrodes to use for Aluminum welding is 1.5% lanthanum oxide (gold color code.). 2% zirconia (brown) or 2% thorium oxide (red) can also be used. Note that zirconia-doped electrodes should never be used for DC welding. A lot of welders like to quote offhand the rule 1 amp for every 0.001 inch of thickness. This applies to steel, stainless, and nickel alloys only. Due to the lower melting point, lower specific heat capacity, and higher thermal conductivity of of Al, this rule should NOT be used for Al! I recommend welding a test piece first with the same joint configuration and thickness of the part you intend to weld. Note that fillet welds require more current than butt welds or edge welds. Start out by using 2/3 amp per 0.001 of thickness, in other words, reduce the current of the above rule by about 30-40% . Make 3 test weld, then check to see if there's any visible penetration on the other side. If you don't see any through-pentration at all, increase the current by about 10-20 amps and test again.

- The typical tensile strength of aluminum sheets can vary depending on the specific grade or alloy being used. Generally, the tensile strength of aluminum sheets ranges from 20,000 to 50,000 pounds per square inch (psi). However, it is important to note that this is a broad range, and the exact tensile strength can be influenced by factors such as the thickness of the sheet, the manufacturing process, and any additional treatments or coatings applied to the aluminum. Therefore, it is recommended to consult the specifications provided by the manufacturer or supplier for accurate information on the tensile strength of a specific aluminum sheet.

- How to distinguish aluminum sheet from magnesium sheet?

- magnesium sheet will react with alkali.

- Which kind of solution should I use while welding aluminum sheet and copper pipe by tin soldering?

- 1, you must use over 350W soldering iron, 2,prepare some borax and tin soldering paster, you can’t use rosin to weld it, 3, polish the pipe to clean with fine abrasive paper and borax, 4, put the pipe and sheet into borax, use the soldering trip to rub on the weldment with some borax. 5, after the pipe and sheet become hot, use the soldering iron with the paster and tin to rub the pipe and sheet in borax, then it can be welded. 6, they can be welded together after welding.

- Which kind of glue can bond two pieces of aluminum sheets?

- you can use tin welding.

- Yes, aluminum sheets can be anodized for aesthetic purposes. Anodizing is an electrochemical process that creates a protective oxide layer on the surface of the aluminum. This layer can be dyed in various colors, creating a wide range of aesthetic options. Anodized aluminum sheets are popular in architectural applications, such as building facades, as they provide a durable and visually appealing finish. The anodized layer also enhances the corrosion resistance and wear resistance of the aluminum, making it suitable for both indoor and outdoor uses. Additionally, anodized aluminum sheets can be further processed through techniques like etching or laser engraving, allowing for the creation of intricate designs and patterns.