20 Mic Aluminum Coated cpp mcpp Film for Laminated Packaging

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

20 mic aluminum coated cpp mcpp film for laminated packaging

Quality: 100% virgin cpp

HS Code: 777309664Processing Type: Multiple extrusion

Thinckness: 8mic-180mic

Main size: Width≤2350mm

Length 18000m/9000m/6000m

Usage: 1)cpp food grade packing film2)cpp printing film, pet release film

3)metalized cpp film,cpp/pet sealing film

4)cpp laminating film

Remark: All the indicators could be customized which includes the thickness, width, length, diameter.

Product Description

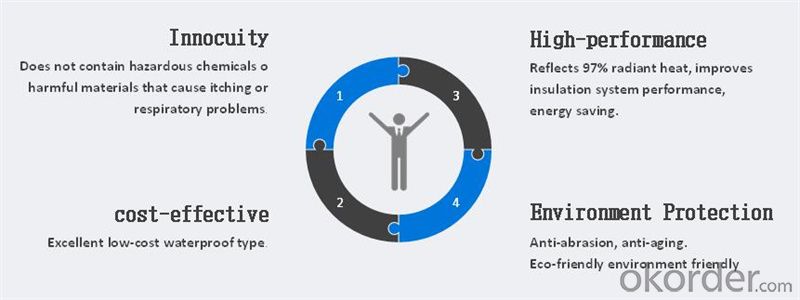

Our Advantage

Superiority of price: we control the whole process from raw materails purchasing to final product manufacturing.

Efficiency advantage: the fastest time of delivery is 7days.

Customization: all indicators could be customized which includes the thickness, width, length, diameter.

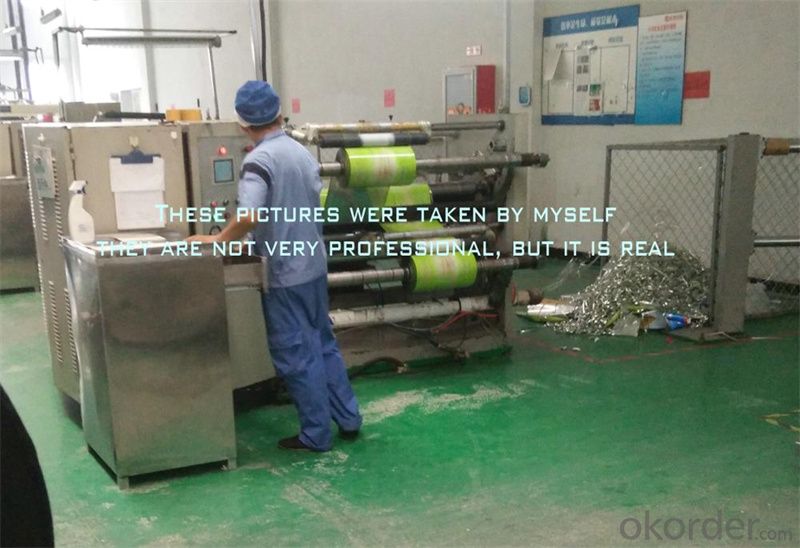

This is our metalized polyester pet film produce line,

you can visit our factory at anytime,

we asked workshop clean and tidy to ensure that the product with high quality and error-free.

Device Show

- Q: What about the glue left behind the plastic film on the door?

- Apply a little bit of hand sanitizer to the scissors, then dig a small hole with the scissors, then scrape them off slowly and then rip them off with your hands.

- Q: What are the factors affecting the permeability of plastic film?

- Film properties. The permeability of polymer film is related to its structure. The permeability of polar film is larger than that of non-polar film, and the amorphous film is larger than crystalline film. In addition, the permeability coefficients of some polymer films are similar to those of saturated vapor pressure. The permeability coefficient of polyethylene and nylon films is several times higher than that of moisture permeability. This is mainly due to the formation of pores between crystals or grains, which facilitates the flow of liquid water.

- Q: What brand is a plastic film on the surface of waterproof coiled material?

- Usually manufacturers directly use their own production, almost no separate circulation of the market, is one of the production process.

- Q: What's the difference between PE plastic film and PVC plastic film?

- PE: flammable, away from flame continues to burn, flame yellow blue, melt dripping, paraffin taste PVC: not flammable, away from the fire that destroyed the flames, yellow green with white smoke, softening without melting, pungent sour PE film is mainly used for industrial products: equipped with membrane, with high tensile strength. High elongation rate, good self-adhesive, high transparency point.

- Q: What are the plastic film types and scope of use?

- PVA coated high barrier film is a strong barrier gas material, and thermal suture, moisture barrier strong polyolefin composite, is a multilayer structure of the film. PVA coating high barrier film, nano layered silicate modified PVA coating on polyethylene film, after printing and composite, the oxygen resistance rate is less than 2cm3/ (M2 ? 24h ? 0.1MPa). The barrier properties are superior to those of EVOH five layer coextrusion film, and the packaging cost is greatly reduced, which can not only ensure the packaging requirements for aseptic packaging all the quality, but also greatly reduces the cost of aseptic packaging of food processing enterprises, solve the technical bottleneck of the three layer coextrusion poor barrier properties of polyethylene packaging film. Can be used for packing beverage, fruit juice, milk, soy sauce, vinegar etc..

- Q: What film plastic is transparent and good for aging?

- Now used for lighting plastic lighting board is more: FRP lighting board and PC (polycarbonate) lighting boardWell, the warranty period for the PC board is 10 years and 15 years, while the better FRP lighting board has a warranty period of 20 years and 25 years.

- Q: How to make a round hole in plastic film

- If it is a film with perforated, hollow metal objects will need to choose according to the size of the round hole relatively hard round, such as diameter of the pipe. Similarly, after heating quickly and vigorously press (weight hit), in need of drilling position, with more drilling, the need for speed is very fast, the instantaneous strength can be great, otherwise the film will scorch damaged.

- Q: Can plastic film protect against ultraviolet rays?

- The transparent film itself UV blocking effect is not good, the general need to add other ingredients, such as color masterbatch, metal particles etc..

- Q: What are the differences between geotextiles and geomembrane?

- The main mechanism is a plastic film impermeable partition dam Water Leakage channel, with its large tensile strength under pressureadapt to dam deformation; and the non-woven fabric is also a kind of polymer material chemical short fiber, through acupuncture or thermal forming, with tensile strength and elongation is higher, it is combined with after the plastic film, not only increases the tensile strength and puncture resistance of plastic film, non-woven fabric and because rough surface, increases the friction coefficient of the contact surface, in favor of composite geomembrane and protection layer stability. At the same time, they have good resistance to bacteria and chemical action. They are not afraid of acid, alkali and salt corrosion.

- Q: What are the factors that affect the barrier property of plastic film?

- Plastic film due to stretching during molding, plastic macromolecules are subject to varying degrees of directional role, respectively, and the rules are closely arranged, the barrier to improve the film. The higher the degree of orientation, the better barrier property. Especially after biaxial stretching treatment, the grain size can be greatly reduced, and the crystallinity can be increased. It can be explained that on the one hand, stretching causes the crystalline particles to become smaller and smaller; on the other hand, the stretching increases the orientation of macromolecules and makes the arrangement more orderly, thus increasing the crystallinity and the arrangement density of macromolecules.

Send your message to us

20 Mic Aluminum Coated cpp mcpp Film for Laminated Packaging

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords