Mylar Lamination Film- 60mm Width Aluminum Foil/Polyethylene

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Structure

Widely used for laminating with EPE insulation, Bubble insulation, woven fabric insulation, etc

● Aluminum foil – LDPE

● Aluminum foil- PET- LDPE

● Clear Transparent PET-Aluminum foil – LDPE

● Aluminum foil-Metallized PET- LDPE

● Metallized PET- LDPE

Product Application

Widely used for laminating with EPE insulation, Bubble insulation, woven fabric insulation, etc

Product Advantage

Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• Environmentally friendly, no smell and not-toxic;

• Smooth and clear surface;

Product Packing

1. Waterproof paper then PVC shrinking Film

2. Kraft paper only

3. Woven cloth

4. Kraft paper or Water Proof Film then Metal/wooden pallet

5. (Also as your request. )

Product Remarks

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and kept from wet and heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

Product Data Sheet

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 33.5 | ASTM D646 |

Thickness | mic | 23.2 | ASTM D646 |

Tensile strength: M. D. X. D. | N/15mm | 13.5 13.5 | ASTM D882 |

Delaminating Values | N/15mm | 1.5 | ASTM D904 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -40°C 130°C | No Delamination No Delamination | ASTM C1263 |

Water vapor permanence | ng/N.s | 1.15 | ASTM E-96 |

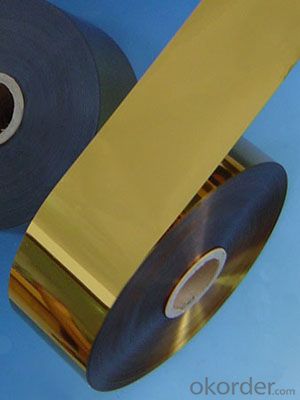

Product Picture

FAQ

1. What is the product keeping conditions?

The Aluminum Foil Facing should be stored at room temperature and kept from wet and heat source.

2. What is the guarantee years of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. What is the delivery time of the order?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: What are the choices of plastic film and plastic film in greenhouse?

- The PE film dominates the total output of plastic film in the agricultural film greenhouse in china. Due to the limitation of production width and electrostatic pollution, the application of PVC film in film greenhouse has been greatly limited.

- Q: Why do you put plastic film on the paved road?

- Plastic film does not have special requirements, as long as it can be covered with water to prevent evaporation. In the cold season construction to cover the mats and other things to keep the temperature.

- Q: What is the raw material of agricultural film?

- Agricultural film raw material is HDPE, commonly known as low pressure, buy this kind of raw material, the most important to see your demand, if the amount of big, you can directly find petrochemical agents.

- Q: What are the composite ways of plastic film?

- The solvent free composite method is a plastic film with pre - coated hot melt adhesive. Press the rollers together with another layer of plastic film. This way, less pollution, energy saving and energy-saving composite section, is the direction of future development. However, because of the high cost of solvent free composite equipment, as well as composite glue and technical reasons, there is still very little domestic use.

- Q: Is it necessary to use disposable plastic film to cover the furniture for brushing latex paint?

- Films are needed to protect the furniture. Or dirty, late difficult to handle.

- Q: Will iron make any pollution when it is melted again?

- Like the plastic film made of polyethylene, polypropylene, EVA and other plastic is generally non-toxic, widely used in food packaging industry. And PVC plastic plastic film due to the addition of stabilizers containing lead and cadmium, it is harmful to humans, but if the use of PVC non-toxic formula (using non-toxic stabilizer and plasticizer, etc.) made of plastic film can be used for food packaging.

- Q: What are the plastic film types and scope of use?

- The biaxially oriented polypropylene film is prepared by the co extrusion of polypropylene particles and then by stretching in two directions. Due to stretching of molecular orientation, physical stability, so this kind of film mechanical strength, good air tightness of transparency and gloss, high tenacity, wear-resisting, is currently the most widely used printing film, generally use the thickness of 20 ~ 40 m, the most widely used is 20 m. The main drawback is the biaxially oriented polypropylene film heat sealing is poor, so generally used as an outer film composite film, such as polyethylene film and composite moisture resistance, transparency, strength, stiffness and printability were ideal, suitable for holding dry food. Because the surface of biaxially oriented polypropylene film for nonpolar, high crystallinity and low surface free energy, therefore, the poor performance of printing, ink and adhesive adhesion, surface treatment and compound before printing.

- Q: How to remove plastic film that is attached to stainless steel door for a long time?

- The blade of the wallpaper blade can be gradually scraped against the surface of the door so that the mucous membrane on the surface can be removed. Pay attention to the window only about 20 degrees, and can not be vertical scraping with the facade. Watch your fingers.

- Q: Are planted steel structure plastic film shed structures?

- The planted steel structure plastic film greenhouse structure does not belong to the category of structures, and the main reasons are as follows:Structures generally refer to places where people are not directly involved in production and living activities. Such as water towers, chimneys, Zhanqiao, dams, reservoirs and so on. Normally, so-called structures are artificial structures that do not have, do not contain, or do not provide human habitation, such as towers, ponds, filters, clarifier, digesters, etc.. An artificial building that has, contains, or provides human habitation, known as a building. The name of the structure is much more in the textbook of water supply and drainage. It should be noted that this definition is not absolute. In water conservancy and hydropower projects, all structures on rivers and channels are called buildings, such as hydraulic structures.

- Q: Why is plastic film made of hand made paste of composite material?

- FRP hand lay up after the release, must be to achieve, but the smooth emergence is very important, because of the characteristics of thin flat and smooth, easy to make glass steel and mould to form two layers, not due to the small defects of the mold surface due to adhesion, so that the surface is beautiful and easy demoulding.

Send your message to us

Mylar Lamination Film- 60mm Width Aluminum Foil/Polyethylene

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords