High Quality PVB Film

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 30000M2 m.t.

- Supply Capability:

- 140000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Production Specifications of High Quality PVB Film :

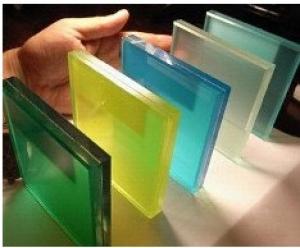

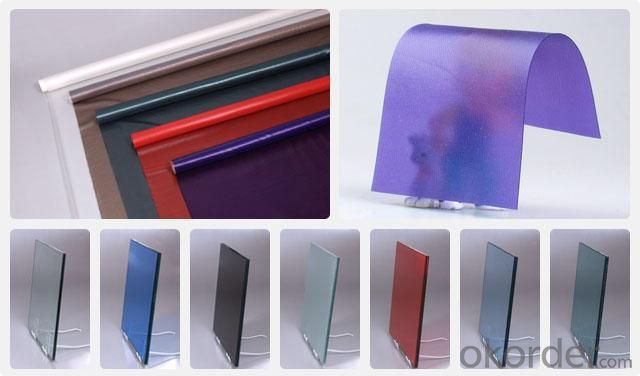

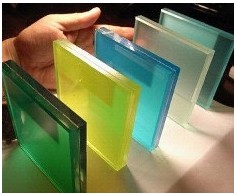

Polyinyl butyral film is made from PVB resin with plasticizer and prepared by the technology of extrusion and calendaring.

I t can be used as the inner layer of sandwich safety glass of cars, locomotive, airplane, tanker, naval vessel etc. It can also be used

as solid adhesive for safety glass, safety mask, building glazing, composite steel plate, etc. It conforms to the enterprise standard of

Q/GHAD 18-2008 .

TDS Of High Quality PVB Film

Item | Value | ||||

E-413J | E-413A | E-413B | E-413C | ||

Volatile content % ≤ | 2.0 | 2.0 | 2.0 | 2.0 | |

Tensile Strength MPa ≥ | 20.0 | 20.0 | 15.0 | 15.0 | |

Elongation @ Break % ≥ | 160 | 150 | 150 | 120 | |

Adhesive Strength MPa ≥ | 8.0 | 7.0 | 5.0 | 4.0 | |

Light Transmission Rate % ≥ | 81.0 | 80.0 | 80.0 | - | |

Fog % ≤ | 0.60 | 0.80 | - | - | |

Colourith% ≥ | 75 | 75 | 70 | - | |

Humid Heat | At 70±2, hum.91%-99%.After 48 hrs, sample no change. | At 60±2,hum. 91%-99%.After 8 hrs, sample no change. |

- | ||

Heat-Resistance | At 70±2,After 48 hrs, sample no change. | At 60±2,After 8 hrs, sample no change. |

- | ||

Cold-Resistance | At -55±2,After 48 hrs, sample no change. | At -55±2,After 8 hrs, sample no change. |

- | ||

Light-proof | Light transmission rate decrease less than 2% under 750W light-source, 100hrs | ||||

Usage of High Quality PVB Film :

With the Featurers of Transparent, heat- resistant, cold -resistant, wet-proof, high elasticity, without impurities, good softness, smooth surface with some roughness, good tensile strength and elasticity , the PVB Film can be widely used in Architecture and others.

Packing of High Quality PVB Film :

Vacuumed by aluminum foil and put into wooden cases , 10 Tons /20 FCL or as customers ' requiements .

- Q: Why should farmers cover plastic film when sowing in the spring?

- 1. warming up and promoting the decomposition and release of soil nutrients2. moisturizing, improve the survival rateSoil moisture, except irrigation, mainly comes from rainfall. After covering the membrane, on the one hand, because of the barrier of plastic film, the evaporation of soil water is reduced and the dissipation is slow; and the water drops formed in the membrane and then fall into the soil table, thereby reducing the loss of soil moisture and protecting soil moisture. On the other hand, the film can also be in the excessive rainfall, prevent the rain poured into the ridge, can play the role of waterlogging.3. promote growth and developmentThe application of plastic film mulching increased soil temperature and humidity, which was beneficial to early growth and rapid growth, and promoted the growth and development of plants. The growth period of plastic mulch is shortened to about one week.

- Q: Build a fleshy plastic film greenhouses, where the best? Why?

- Plastic film is not a good place, but what kind of good?.

- Q: What are the factors affecting the puncture strength of plastic film?

- The general physical and plastic film thickness, tension, the heat and other factors, but also has a relationship with the processing of materials used in production, if not assured the puncture strength of plastic film is not qualified, can choose the market force commonly used CCY-02 puncture tester to check.

- Q: What PE plastic film?

- Many PE film friends, many of them in the forefront of the operator, responsible for technology. Liquid has many PE particles, including low density, metallocene, linear and so on

- Q: Would you please put a plastic film on the bottom of the tent and put a plastic film on the top of the tent for lightning protection?

- Plastic film is waterproof and non-conductive, and if you can completely guarantee the insulation inside and outside the tent, then even if there are arcs outside the tent, it doesn't matter to you. So, in that case, it still works.

- Q: Can damp wood floors be made of plastic sheeting?

- And high quality floor adopts high-density substrate, its excellent moisture resistance, water absorption, thickness expansion rate is much smaller than the national standard. In addition, special wear-resistant layer, decorative paper, balance layer, can be good substrate closed, to ensure that the overall moisture resistance of the floor better.

- Q: How to quickly remove the plastic film on the floor tiles?

- 1, ceramic tile daily cleaning can choose detergent, soap and other cleaning. 2, with soap, add a little ammonia and turpentine mixture, cleaning tiles can make tile more luster. 3, polished brick should be regularly waxing, the time interval is 2-3 months is appropriate. 4, such as brick surface scratches, can be applied in the scratch of toothpaste, wipe with a dry cloth can be repaired. 5, brick and brick crevice can be used regularly decontamination paste to dirt, and then brush a layer of waterproof agent in the gap, can prevent mold growth. 6, tea, coffee, beer, ice cream, grease and other pollutants using sodium hydroxide or potassium bicarbonate solution. 7, ink, cement and other pollutants use hydrochloric acid, nitric acid and other dilute solution. 8, paint, paint and other pollutants use special cleaning agent.

- Q: Is the foundation covered with film or damp proof powder?

- 1, I do not know what is the principle of moistureproof powder?. It is estimated that it is additive. But not added to mortar, doubt the function.2, the film will be better, but the follow-up construction is easy to damage, durability is limited, it is better to do a waterproof.3, on the foundation moistureproof, equal to did not do. It is no use crossing a block of water in the middle of the pool. Damp proof should be done below ground level.4, I don't think the film is better than the traditional damp proof layer. Can the height on the ground, construction (brick), can play a role of natural moisture barrier; or on the ground part of the wall construction waterproof isolation layer.

- Q: Rigid plastic film problems

- Generally there are three kinds of materials: PC, PET, PVCNormally, PC and PET belong to high-grade materials, the price is high, basically are used in electronic industry, PVC films are more general 0.05mm-0.125mm estimation can meet the requirements, but the material is environmental protection, which is also produced HCl toxic gas when burning, if there is high quality requirements of export or can not be used, see your customer requirements, other film may also be used for this, such as PE, but probably not hard enough

- Q: Why is plastic film made of hand made paste of composite material?

- FRP hand lay up after the release, must be to achieve, but the smooth emergence is very important, because of the characteristics of thin flat and smooth, easy to make glass steel and mould to form two layers, not due to the small defects of the mold surface due to adhesion, so that the surface is beautiful and easy demoulding.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1988 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | North America; South America; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Central America; South Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 20,000 square meters |

| No. of Production Lines | Above 6 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

High Quality PVB Film

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 30000M2 m.t.

- Supply Capability:

- 140000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches