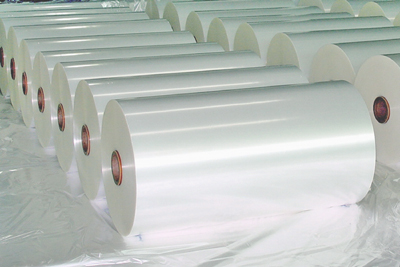

PVB Film Roll For Safety Glass

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2 TONS m.t.

- Supply Capability:

- 100000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of PVB film for safety glass:

PVB interlayer is the abbreviation of Polyvinyl Butyral. PVB film is made from PVB resin and plasticizer. It is a non-toxin and smell-free soft sheet materiel with thickness between 0.2mm-2mm, the best material for the interlayer of safety glass.

Features of PVB film for safety glass:

Color: clear

Thickness: 0.38mm

Max width: 2500mm

Length: 200m/250m/100m

Application: building glass

Pvb building film roll for safety glass

Thickness:0.38mm

Material: 100% pvb resin

Color: ocean blue

Max width: 2500mm

Package of PVB film for safety glass:

A. the pvb film is insulated with PE film, cased into an aluminum foil bag, then vacuum sealed, and lastly into plywood box or fiber can.

B. There should be quality certificate, packing list in the package. The marks of moisture proof, shock proof and sunlight proof should be labeled.

C. the width 1250mm is packaged in the fiber can, and the width more than 1250mm is packaged in the plywood box.

Production and loading of PVB film:

- Q: Why would you wrap plastic film in a tree?

- Wrapped plastic is to keep moisture, in order to prevent evaporation of water and die plants, and afraid of the wound fungal infection.

- Q: What are the choices of plastic film and plastic film in greenhouse?

- Film greenhouse plastic film because of low price and convenient use, can effectively improve the crop growth conditions, increase yield and improve quality, so in the greenhouse at home and abroad covering the rapid development.At present, the film products used in film greenhouse mainly include PVC film, PE film and EVA film. These three kinds of mulching materials are often used in film greenhouse.

- Q: What is Matt BOPP film, or matt plastic film?

- Matt is generally matt surface roller pressing out, Matt film is like the role of frosted glass

- Q: Build a fleshy plastic film greenhouses, where the best? Why?

- General is the use of non drip defogging the best. Recommend the use of Po film, as to the use of which manufacturers, generally near the can. Big picture or worry, I can try to help you.

- Q: What PE plastic film?

- Many PE film friends, many of them in the forefront of the operator, responsible for technology. Liquid has many PE particles, including low density, metallocene, linear and so on

- Q: What is the raw material of agricultural film?

- Agricultural film raw material is HDPE, commonly known as low pressure, buy this kind of raw material, the most important to see your demand, if the amount of big, you can directly find petrochemical agents.

- Q: New car tires have a transparent plastic film, will not be a problem car, new tires, or the car is the same when you leave the factory?

- Tire manufacturers in the purchase, some luxury cars in order to reflect the overall appearance of the car, the tire has a layer of transparent plastic film dirty material is to prevent dust, as long as four tires are new tyres, front two sign must be the same, and wear are the same

- Q: Plastic film surface corona treatment, the bigger the better?

- The surface tension requirement of the general printing processing film is 38 42dyn; the surface tension of the composite processing film is required to reach 42 -54dyn; the surface tension of the film processed by vacuum aluminizing is not less than 42 50dyn.

- Q: Masks that layer of white plastic film is used for what?

- Masks that layer of white plastic film is prevented when the mask folded together, to prevent the loss of nutrition, to prevent deformation of the mask.

- Q: Why should a plastic film be covered after civil construction?What's the point? Do you have any requirements for plastic film?

- The plastic film has no special requirements, as long as the cover to prevent water evaporation. In the cold season construction to cover the mats and other things to keep the temperature.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 2009 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East;Eastern Asia; Western Europe; Central America; |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Wenzhou Port |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | Above 10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High;Average |

Send your message to us

PVB Film Roll For Safety Glass

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2 TONS m.t.

- Supply Capability:

- 100000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches