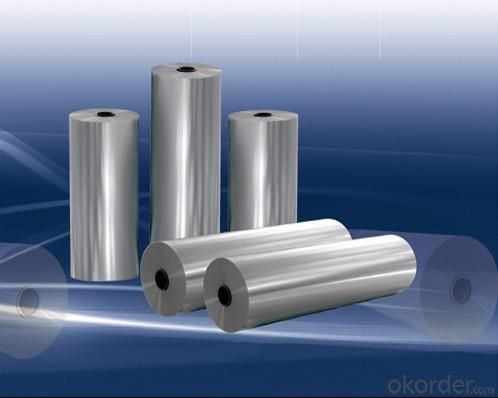

PET Film

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2 TONS m.t.

- Supply Capability:

- 20000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PET Metalized Film Lamination

Description:

1. Thickness: 38 micron

2. Width: under 1250mm

3. Paper core: 3" (76mm) or 6" (152mm)

4. Feature:

1) Smooth and clear surface

2) Good printing quality and fireproof properties

3) Heat resistant, water proof, stable at high temperature or in boiled water

4) Environmentally friendly, no smell and non-toxic

PET Metalized Film

Using polyethylene as carrier, it can be used for very wide applications because of its excellent mechanical and chemical properties. it is an ideal material to make flexible packages as the metalized layer creates a great barrier to oxygen, light, and moisture and as a result prolongs product shelf life substantially.

On the other hand, it can be laminated to cardboard to make fabulous packages. It can also be used to make stationery and toys such as adhesive tapes, stickers, or used as varnishing film.

- Q: Excuse me, where can I buy a special transparent plastic film?

- Different transparent plastic films are needed for the purpose of isolating ultraviolet light from the sun and varying light permeability, such as 50%, 70%, etc..

- Q: Can plastic film be printed?

- Plastic film can be printed, the current printing technology is already very mature, you can print 3D. Now there are plastic film printers.

- Q: What is the difference between a thin film keyboard and a mechanical keyboard?

- The film is the two keyboard circuit boards cover together, separated by a layer of film, want to get the same network there will be a hole, you can imagine a sandwich like, then sandwich top also add a layer of plastic film, each key corresponds to the plastic nipple film above a rising (you you can see, the keys to pry open) key is pressed, the plastic nipple will be under the pressure of the two layer circuit board corresponding to the position of the hole together, then the computer will know which key is pressed.

- Q: What color glass, plastic film or supplementary light source should be chosen for growing vegetables in greenhouse?

- Hello friends, plastic greenhouse planting eggplant fruit vegetables suitable plastic film is EVA film, PO membrane two kinds, PO membrane price is too high, and use the most common or EVA film.EVA film transmittance, high temperature, fast, good insulation, the price is suitable for every square in a piece of five to two blocks between.Others, such as poly vinyl non dripping film, this is to filter UV, affecting the coloring of vegetables. Grouting film is cheap, the disadvantage is that the temperature is too fast, low transmittance, no drop is too short.

- Q: What is the raw material of agricultural film?

- Agricultural film raw material is HDPE, commonly known as low pressure, buy this kind of raw material, the most important to see your demand, if the amount of big, you can directly find petrochemical agents.

- Q: What's the quota for PE membrane isolation layer?

- Specification for polyethylene tape: its thickness * width * length, in fact, determines what thickness of adhesive tape to use. For example: in order to strengthen the level level of corrosion, corrosion thickness of 1.0mm; corrosion level reinforced, corrosion thickness of 1.4mm; according to the lapping mode with internal and external anticorrosive adhesive tape, tape thickness determination. According to the construction mode of adhesive tape winding, determine the width of anticorrosive adhesive tape. Don't use the manual winding tape is too wide, the construction workers when the efforts are not easy to control, it is best not to exceed 150mm wide; manual mechanical winding (with some simple mechanical and visual), but the maximum width is 230mm; the mechanical winding tape width appropriate to relax, but preferably not more than 300mm.

- Q: Method for removing stainless steel plastic film

- Because of their environmental protection characteristics, many water-soluble films have attracted extensive attention in developed countries all over the world. Abroad are Japan, the United States and France etc. the production and sales of such products, such as the United States W.T.P company, C.C.L.P company, GRENSOL company in France and Japan synthetic chemical company and so on, the user is also some well-known large companies, such as Bayet (Bai Er), Henkel (Henkel), Shell (Shell) etc..

- Q: What plastic films can be made into plastic bags?

- Yes, many kinds of materials can be used in a mixed way, but generally add third ingredients to achieve satisfactory results. The two materials are simple mixing, and most of them will affect the quality of the film

- Q: Why should a plastic film be added to the new cement road?

- The new cement road needs a layer of plastic film for better maintenance.

- Q: Are planted steel structure plastic film shed structures?

- Buildings differ from buildings in terms of structures, such as walls, roads, dams, wells, tunnels, water towers, bridges and chimneys. In many cases, "buildings" are relative to "structures", although sometimes they are confused. It is also a fixed human creation. The word "building" focuses on its aesthetic image or enclosure of the available space, which emphasizes its direct appreciation or access to activities. Structures tend to refer to other "fixed" human creations, such as "water blocking", to meet a particular need for use and serve indirectly".

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 2009 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East;Eastern Asia; Western Europe; Central America; |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Wenzhou Port |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | Above 10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High;Average |

Send your message to us

PET Film

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2 TONS m.t.

- Supply Capability:

- 20000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches