Packing and Lamination Film-12mic MPET/12mic PET/10 mic Polyethylene

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Structure

Widely used for laminating with EPE insulation, Bubble insulation, woven fabric insulation, etc

● Aluminum foil – LDPE

● Aluminum foil- PET- LDPE

● Clear Transparent PET-Aluminum foil – LDPE

● Aluminum foil-Metallized PET- LDPE

● Metallized PET- LDPE

Product Application

Widely used for laminating with EPE insulation, Bubble insulation, woven fabric insulation, etc

Product Advantage

Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• Environmentally friendly, no smell and not-toxic;

• Smooth and clear surface;

Product Packing

1. Waterproof paper then PVC shrinking Film

2. Kraft paper only

3. Woven cloth

4. Kraft paper or Water Proof Film then Metal/wooden pallet

5. (Also as your request. )

Product Remarks

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and kept from wet and heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

Product Data Sheet

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 33.5 | ASTM D646 |

Thickness | mic | 23.2 | ASTM D646 |

Tensile strength: M. D. X. D. | N/15mm | 13.5 13.5 | ASTM D882 |

Delaminating Values | N/15mm | 1.5 | ASTM D904 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -40°C 130°C | No Delamination No Delamination | ASTM C1263 |

Water vapor permanence | ng/N.s | 1.15 | ASTM E-96 |

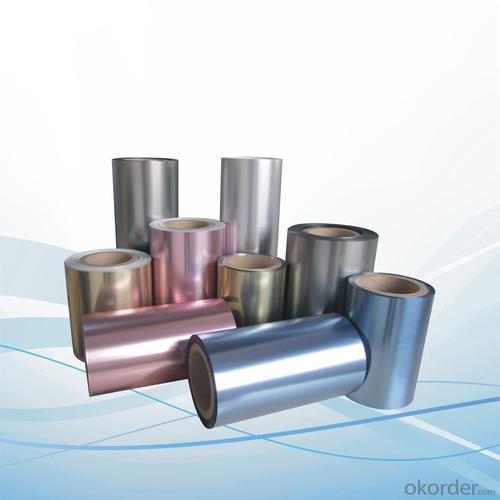

Product Picture

FAQ

1. What is the product keeping conditions?

The Aluminum Foil Facing should be stored at room temperature and kept from wet and heat source.

2. What is the guarantee years of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. What is the delivery time of the order?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Why should farmers cover plastic film when sowing in the spring?

- The film mulching can improve the soil and ground temperature and moisture status, to improve the soil temperature, soil water content, improve soil properties and improve soil nutrient status and fertilizer utilization rate, improve light conditions, reduce weeds and pests.

- Q: A concrete cover film, under what circumstances to cover, what does not cover

- Because the external temperature and the internal temperature of concrete can not be too different,Otherwise, thermal stress. Internal expansion. External contraction. Produces cracks

- Q: What's the best way to eliminate static electricity with plastic film?

- Ion stick ion stick can produce a lot of air with positive and negative charges, can be charged with neutralize when the surface charge is negatively charged, it will attract positive charge in the air, when the surface charge is positively charged, it will attract gas flow of negative charges in, so that the static electricity on the surface of the object and achieve the purpose of eliminating static electricity.

- Q: How to detect the surface tension of plastic film?

- To judge the smoothness of the surface of the plastic film by hand, the more smooth the surface of the film is, the better the surface treatment of the film is.

- Q: After decorating, how can the plastic film on wooden board be peeled off?

- Plastic film removing method:1, can use a thick plastic bags, hot water deposited for a while, and then deal with2, can be treated with diluted alcohol.3, sprinkle with hot water and then use the shovel eradication.4, you can use toluene or gasoline, that is, the taste is a little big5, hand gradually tear, or can use steel wire ball gently wipe can.

- Q: Is it beneficial or harmful to wrap trees in plastic film?

- The principle of the above three kinds of trees to wet method of the same, but some differences in the choice of materials, the trunk with plastic film sealing, insulation and moisture than the artificial water mandatory, traditional maintenance is more stable and more uniform, the adverse impact of weather on the trees and to minimize hurt. Therefore, in the "39" and "dog" day day, must not remove film. The growth cycle must be followed for 1 to 2 years and the film can be removed before the trees are stable. The trunk moisturizing operations can also be carried out before planting trees, which is more convenient.

- Q: Can the barrier in the refrigerator be covered with plastic film?

- The shelf in the refrigerator can be affixed with plastic film according to the use, and no influence on the use of the refrigerator.

- Q: Do you want to remove the wrapping plastic film from the new mattress?

- Restoring the inherent elasticity and comfort of the mattress. There is a bed on the mattress. The sheets are very sanitary. It is not necessary to keep the plastic film in it.

- Q: Is it good to use paper bags or plastic film bags?

- In fact, the plastic film is not good, because the film is easy to produce electrostatic glue sand and other hard particles (hardness greater than disk) due to careless small scratches on the surface of the film and the surface in close contact to remove the disc, so the theory of paper (shell) bag is better than the film I hope this helps for you

- Q: Why should a plastic film be covered after civil construction?What's the point? Do you have any requirements for plastic film?

- The plastic film has no special requirements, as long as the cover to prevent water evaporation. In the cold season construction to cover the mats and other things to keep the temperature.

Send your message to us

Packing and Lamination Film-12mic MPET/12mic PET/10 mic Polyethylene

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches