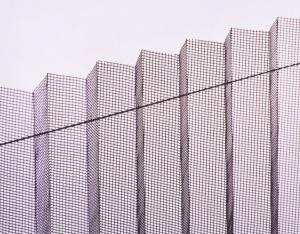

High Quality PET Film

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 2000 Tons Per Month kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

1. Specifications of PET Film:

Higher mechanical strength and toughness

Good flatness and coefficient of friction

Excellent dielectic property

Good resistance to most common solvents,moisture,oil etc

Good barrier of gas

2. Usage of PET Film:

FET Filmsare used for packaging,printing,laminating,decoration etc etc.

3. Packaging & Delivery of PET Film:

One 20GP container can be loaded about 10-15tons.

By sea or by air all available.

- Q: Is computer screen protective film effective?

- To be sure, it didn't work. I bought a protective film, or it was more expensive

- Q: What is the protective coating for car paintwork?

- Car paint protective film, also known as the body invisible protective clothing. It is a kind of high performance film. Thin and transparent, with super toughness. Can effectively prevent scratches, pebbles, sand particles hit. It also fits perfectly on the surface of the paintwork to insulate the paint from the air

- Q: The protective film is not just to buy a reverse beat back, transparent paper pasted on the racket above, it is how to use?? Is it one-off or multiple?

- The protective film is not just to buy a reverse beat back, transparent paper attached to the racket above, it is a one-time.

- Q: What's the difference between radiation and static? How can I know the protective film is anti-static or not? What harm can static do?

- To put it simple, static is on the surface of screen. It's not harmful to human body. But it does exert influence on using to some extent. Radiation is emitted from interior of screen. It's harmful to human body. It can damage human skin. For example, it can accelerate aging of the outer layer of skin. It is easy to know whether the protective film is anti-static. Puting a piece of thin paper on the screen. If the paper can be sticked to the screen, then the screen is static. You cover the screen with the prtective film (or simply put it on the screen) and then put the thin paper on the screen again. If the paper can't be sticked to the screen, it indates the static is separated by the protective film, meaning the protective film is anti-static.

- Q: The PET protective film appears to be a solution to the problem

- PET protective film in use after a period of time will be two wings, the main reason for this phenomenon is a protective film on the protection and profiles in the paste process, the degree of tension is large, in the post after, in high temperature environment, the retraction phenomenon is not necessary,

- Q: The mirror protective film is what, how should the truth!

- The common protective film just scratch the most basic function, mirror protective film protective film is a functional OK8 brand launched the first one in the scratch with new technology, the mobile phone background lights off when the protective film provides the user with a mirror function, as well as anti spy film, matte film, AR film other types of protective film, LZ if you want to further understand can go to the OK8's official website. There is this brand of protective film, the price is similar to the highest inside the protective film

- Q: The color of the aluminium-plastic panel is white without protective film. But I've seen other colors that looks like it's painted.

- This shows that the quality of the coating of the aluminium-plastic panel you bought is not good. The paint on the surface of the panel should be very even and consistent. There shouldn't be any dark stripe or marks or shades of the same color which usually appear in spraying processing.

- Q: How to remove the protective film on the door in a quick way?

- Maybe the weather is too cold, I couldn't tear it off no matter how hard I tried. I could only dig a little down from the door at a time. It's really painful. Then I heat the film with electric hair drier for about half an hour. And then gently pull it down from the door.

- Q: Do I need to tear off the protective films on household appliances?

- Yes, you need to. It will be good to the heat dissipation of the appliances this way! And the visual effect is better this way too.

- Q: Decoration ground protection film how to paste more convenient and beautiful? Is there a way to introduce it?

- The whole process of home decoration involves many links. If the front construction is not finished, it will cause unnecessary trouble and loss to the subsequent construction and use.

The technical process and the quality of the products the production of composite materials of our company are in the leading position in domestic, regional sales mainly for overseas markets. Our company is extremely advantageous geographical conditions.

1. Manufacturer Overview

| Location | Jiangsu,China |

| Year Established | 1998 |

| Annual Output Value | Above US$ 75 Million |

| Main Markets | Northern Europe, North America, Eastern Asia, Eastern Europe, Southeast Asia, Western Europe, Southern Europe |

| Company Certifications | National Industrial Products Production License |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Jiangsu |

| Export Percentage | 5% -10% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 66000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

High Quality PET Film

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 2000 Tons Per Month kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches