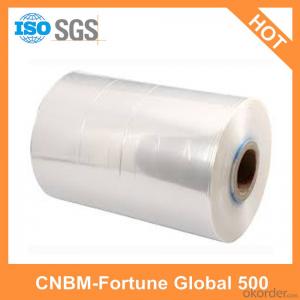

TPU Film for Air Kite Bladder of CNBM in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 1 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Introduction of TPU Film

Compared with the PU film, this kind of TPU film is with:Better elasticity, waterproofing, wear resistance, tear resistance and anti-yellowing.High temperature resistance and cold resistance.

Good for outdoor usage.High resistance to oils, grease and solvents.Good resistance to weather exposure.

2.Application of TPU Film

Household: shower curtain, table cloth, raincoat, umbrella

Bags: cosmetic bags, ziplock bag, cooler bags(liners)

Stationery: book cover, card holders/jackets, binders

3.Advantage of TPU Film

lightweight——low density 0.928 g/cm3

Durability——due to it’s good flexing and cold resistance

Good toughness

easy edge-tear processing, soft hand feeling

Available for silk screen and offset printing

Non-toxic and without plasticizer, can reach the standard like: FDA, REACH,ROHS,EN71-3

The similar price VS PVC, but more eco-friendly

4.Packing of TPU Film

CNBM TPU film is packed by Seaworthy Packing

5.Pictures of TPU Film

6.Specification of TPU Film

Item Name: TPU film

Thickness: 0.025MM - 1.0MM

Total Weight: 20 - 1300g/m²

Color of TPU Film: Translucent

Width: 100-200CM

7.Remarks

Our TPU products have passed the inspection of many international well-known tests such as SGS, ASTM, JIS, FDA and so on. Our TPU products are environmental friendly, non-toxic, water resistant, anti-yellowing, hydrolysis resistant, cold tolerant, high temperature resistant and good tearing resistant. Our TPU materials are not only applicable to the modern production field of articles for daily use, but also suitable for military - industrial complex, medical, electronics and other production areas such as for cricket bat, clothing, shoes, medicines, national defense, electronics, packaging materials, Inflatable products, waterproofing material, stone chip protection, high-end building sticker, solar protection film and so on.

8.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Do I need to tear off the protective film on the mattress?

- It's not a "need" issue. It's a "must" issue. Why? The most important reason is that the film is not breathable. And it affects the comfortableness of the mattress and let alone its hygroscopicity. If you are afraid the mattress gets dirty, you can do as what the former answer said--buy a mattress cover. It's not expensive.

- Q: Cell phone protective film on the small label to tear off the top, as well as how to remove plastic glue?

- The physical properties of ethanol are mainly related to the properties of low carbon straight chain alcohols. The hydroxyl radical in the molecule can form hydrogen bonds, so the viscosity of the alcohol is large, and the organic compounds with similar molecular weight are not so great

- Q: How to clean the glue marks left by the protective film on the stainless steel plate of the light in the living room?

- All organic solvents work.

- Q: What properties does the glue on the glass protective film have? Why doesn't its adhesion change when it meets water?

- Usually the glue on the glass protective film is acrylic adhesive. Its adhesion will be badly affected when it's exposed to water for a long time.

- Q: Excuse me, what reason is mobile phone protection film stuck to mobile phone screen protect film to be able to bubble?

- There are two kinds of foaming reasons, one is in the air, there are two dust wipe clean, this is all right, the first time I posted OK8 film too, thought is broken, fortunately have posted against the instruction above, teach me how to do, okay, squeezed out is, do not use nail squeeze film will bad ~ Cabu out a card package,

- Q: What does it mean that a protective film is anti-blue-ray?

- Anti-blue-ray protective film can weaken the blue ray of the screen. It would not be so dazzling that it can ease visual fatigue. Blue ray is the light emitted LED screen. It's a component of artificial light. It's bad to the eyes looking at the screen for a long time.

- Q: Is there a protective film on the surface of the LCD screen? Can you wipe it directly with a wet cloth?

- You can wipe with a damp cloth, but don't get too wet. It's troublesome to run down the water.In fact, the water should not be used in the end? You can refer to the computer manufacturer's user manual: it says clearly: "wet cloth can be used to clean.". So you can rest assured. Only dedicated liquid crystal cleaners are better at clear dirt.

- Q: What are the requirements for PE protective films?

- The excellent mechanical properties: meet user requirements of tensile strength, elastic modulus and elongation etc..

- Q: How to deal with the stains on mobile phone protective film?

- To buy a new scoth tape and use it to clean up.

- Q: The use of the protective film

- It can cover a lot of products, like electronic products, plastics, mobile phone screens, etc.

Send your message to us

TPU Film for Air Kite Bladder of CNBM in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 1 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches