TPU Film Used for Medical Devices of CNBM in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Introduction of TPU Film

Compared with the PU film, this kind of TPU film is with:Better elasticity, waterproofing, wear resistance, tear resistance and anti-yellowing.High temperature resistance and cold resistance.

Good for outdoor usage.High resistance to oils, grease and solvents.Good resistance to weather exposure.

2.Application of TPU Film

Pallet Wrapping

Compacting & Bunding

Shipping

Handling & Protection

Moving & Storage

Garden

Home

ndustrial & Commercial

DIY

3.Advantage of TPU Film

lightweight——low density 0.928 g/cm3

Durability——due to it’s good flexing and cold resistance

Good toughness

easy edge-tear processing, soft hand feeling

Available for silk screen and offset printing

Non-toxic and without plasticizer, can reach the standard like: FDA, REACH,ROHS,EN71-3

The similar price VS PVC, but more eco-friendly

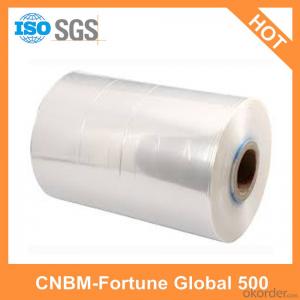

4.Packing of TPU Film

CNBM TPU film is packed by Seaworthy Packing

5.Pictures of TPU Film

6.Specification of TPU Film

Model: TF series | Origin:Jiangsu China | Materials:TPU film |

Depth:0.012-1(mm) | width:1-2(mm) | Tensility:OK |

Air permeability: Low penetration | Property instruction: Transparent | |

1)thickness0.012mm~1mm

2)width:1-2 m

3)longth:<(=)1500m< span="">

4)colour:can be coloured as requirements

5)180° Strip Force:0.3N/25mm~3.0 N/25mm

6)viscous force(40,1kg):>(=)24h

7.Remarks

Our TPU products have passed the inspection of many international well-known tests such as SGS, ASTM, JIS, FDA and so on. Our TPU products are environmental friendly, non-toxic, water resistant, anti-yellowing, hydrolysis resistant, cold tolerant, high temperature resistant and good tearing resistant. Our TPU materials are not only applicable to the modern production field of articles for daily use, but also suitable for military - industrial complex, medical, electronics and other production areas such as for cricket bat, clothing, shoes, medicines, national defense, electronics, packaging materials, Inflatable products, waterproofing material, stone chip protection, high-end building sticker, solar protection film and so on.

8.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Is there any way to tear off the protective film on furniture that is used for too long?

- Blow the film with electric hair drier for half an hour. When the film gets soft, you can gently pull it by hands to tear off the whole film.

- Q: The ways to remove the protective film on household appliances

- I suggest you not to use fire to burn it. You an use a piece of rough cloth or the cloth we use to do the dishes. If you are afraid to scratch the surface, you can slowly wipe it with some toothpaste. If wipe it using steel bush with water, the color of the metal surface may change.

- Q: Performance index of PE protective film

- 2. low viscosity protective filmCharacteristics: thick (0.03m + 0.003), width (less than 1.3), high (100-1000), substrate (PE), peel strength (10-20g/cm), temperature (60), stretching rate (>400)Purpose: tack stability, good adhesion, then peeling performance is good, no glue residue phenomenon for steel mirror plate, titanium plate, smooth plastic, silk screen, Ming brand and so on.3. medium and low viscosity protective filmCharacteristics: thick (0.03m + 0.003), width (less than 1.3), high (100-1000), substrate (PE), peel strength (30-50g/cm), temperature (60), stretching rate (>400)Purpose: tack stability, good adhesion, then peeling performance is good, no glue residue phenomenon for furniture Polaroid plate, stainless steel plate, ceramic tile, marble, artificial stone and so on.

- Q: What to do if the adhesion of the PE protective film is too high?

- Recently, the adhesion of PE protective film is determined by the thickness of slica gel. Not long ago, when making protective film for the screen of VDOO mobile phone, the company had the same problem. High adhesion means high thickness. When the whether is hot,the slica gel will expand when heated and contract when cooled making it look like the screen is sweating,which is call overflow for short in jargon. Therefore, make sure the adhesion is not too high, otherwise it will be difficult to tear the film down. The VDOO company did many experiments when designed the film and finally found the appropriate data of thickness. Besides, taking the thickness into consideration, the purposes of flatness, high resisitance to scratches and high clarity also achieved.

- Q: Why should tear off the protective film on kitchen ventilator?

- It must be torn off. And it affects the appearance of the kitchen ventilator.

- Q: What's the different between stretch film and protective film?

- Sretch film is self-adhesive. And the surface of protective film is coated with a layer of glue. Stretch film is similar to the preservative film we often use. But stretch film is used in industry. Preservative film is used on foodstuff. Protective film is used on the screen of mobile phone. I don't know whether I made it clear.

- Q: What's anti-blue-ray film used for?

- It has function of anti-ultraviolet-rays that can reflect visible light of harmful rays of 380nm-420nm and short wave blue ray. It's 100% anti-ultraviolet-rays of UV400. It can protect the eyes in particular.

- Q: What to do if the protective film on stainless steel plate can't be removed because it's used for too long?

- Give alcohol a try.

- Q: What's the function of the protective film coated on cup lid?

- The plastic film coated on the lid of thermos cup is a kind of packaging material for goods, used to protect the good from scrates during transpotation and sell. You should tear it off before using the cup.

- Q: Composite wood floors above a transparent protective film began to fall off, what should I do?

- Two, it is antifouling protective film, which can be dipped into white cement with a towel.Three, tile wax film, with a dry towel to scrub, scrub with banana water, also can use talcum white cement scrub.

Send your message to us

TPU Film Used for Medical Devices of CNBM in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords