Glass Grinding Wheel

Glass Grinding Wheel Related Searches

Glass Grinding Equipment Grinding Wheel For Drill Grinding Wheels For Steel Grinding Wheels For Metal Diamond Surface Grinding Wheels Vitrified Grinding Wheels Large Grinding Wheel For Sale 6 Diamond Grinding Wheel Diamond Coated Grinding Wheels Rubber Bonded Grinding Wheels Grinding Wheel Balancing Resinoid Grinding Wheels Mounted Point Grinding Wheels Surface Grinding Wheels For Stainless Steel Grinding Wheel Grade Selection Diamond Grinding Wheels For Steel Surface Grinding Wheels For Hardened Steel Model Glass Block Construction Glass Scaffolding Wheels Milled Glass Fiber Aluminum Wheels Glass Fiber Mat Surface Grinder Wheel Selection Glass Fiber Filler Fiberglass Roving Grinding Tools For Metal Glass Vessel Sinks Wheel Sale Fiberglass Filament Winding MachineGlass Grinding Wheel Supplier & Manufacturer from China

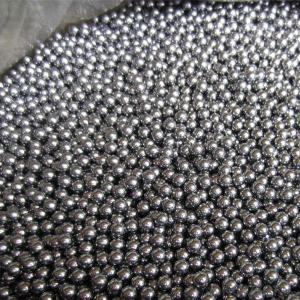

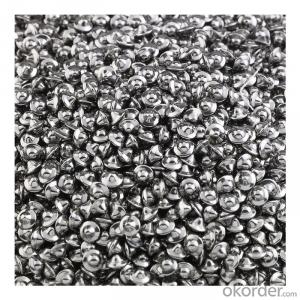

Glass Grinding Wheel is a specialized tool designed for shaping and finishing glass surfaces. These wheels are made from abrasive materials and are used in various industries, such as glass manufacturing, construction, and automotive, where precision and quality are paramount. The product is engineered to provide a smooth finish and efficient grinding capabilities, making it an essential component in glass processing.The application of Glass Grinding Wheel spans across a wide range of scenarios, including cutting, polishing, and shaping glass materials. It is particularly useful in the creation of glass artwork, the production of glass windows, and the repair of automotive glass. Professionals in these fields rely on the durability and performance of Glass Grinding Wheel to achieve the desired results with precision and efficiency.

Okorder.com is a leading wholesale supplier of Glass Grinding Wheel, boasting a vast inventory that caters to the needs of various industries. As a reputable platform, Okorder.com ensures that customers have access to high-quality products at competitive prices, making it a go-to destination for businesses seeking to purchase Glass Grinding Wheel in bulk.

Hot Products