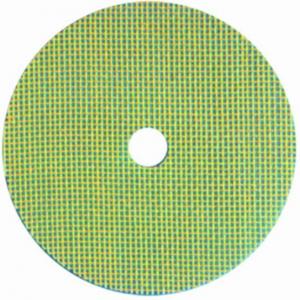

Fiberglass Silicone Fabric for Grinding Wheel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FIBERGLASS YARN is made from different glass fiber filaments, which are then gathered and twisted into one individual yarn. Characteristics :consistent linear density, Application: Mainly used for weaving various reinforce, insulation, anticorrosion, heat insulation fabric and sleeves etc. We can supply different shapes and roll weight, such as milk bobbin, 3.5kg big and 1.0g /0/5kg small paper bobbin |

style | Weave pattern | Yarn description | Count(in) | Weight (g/m2) | Thickness (mm) | |

warp | fill | |||||

116 | plain | ECD450 1/2 | ECD450 1/2 | 60 x 60 | 108 | 0.095 |

2116 | plain | ECE225 1/0 | ECE225 1/0 | 60 x 58 | 105 | 0.09 |

2165 | plain | ECE225 1/0 | ECG150 1/0 | 60 x 52 | 123 | 0.10 |

7628 | plain | ECG75 1/0 | ECG75 1/0 | 44 x 31 | 200 | 0.18 |

3732 | twill | ECG37 1/0 | ECG37 1/0 | 48 x 32 | 430 | 0.43 |

3784 | satin | ECG37 1/2 | ECG37 1/2 | 44 x 35 | 870 | 0.80 |

| Remark: The above data are only the representative products, there are different threads, such as 1/3,2/2,2/3,1/5……etc. Also have C-Glass yarn. |

- Q: Can fiberglass fabric be used for insulation in silos?

- Yes, fiberglass fabric can be used for insulation in silos. Fiberglass fabric is known for its excellent thermal insulation properties, making it a suitable choice for insulating silos. It can effectively prevent heat transfer, keeping the temperature inside the silo stable and protecting the stored materials from extreme temperature fluctuations. Additionally, fiberglass fabric is resistant to moisture and chemicals, making it a durable and long-lasting insulation material for silos.

- Q: Is fiberglass fabric suitable for making backpacks and bags?

- Yes, fiberglass fabric is suitable for making backpacks and bags. It is known for its exceptional strength, durability, and resistance to tearing or puncturing. Additionally, fiberglass fabric is lightweight and has excellent insulation properties, making it an ideal choice for outdoor gear like backpacks and bags.

- Q: Which is more durable, stone cotton or glass cloth?

- It should be said, stone cotton heat-resistant better. I have experienced many years of melting glass fiber cloth and have no experience in melting asbestos. The melting temperature of glass is only more than 1000 degrees, and the melting temperature of asbestos is not found.

- Q: Can fiberglass fabric be used for making backpacks or luggage?

- Yes, fiberglass fabric can be used for making backpacks or luggage. Fiberglass fabric is known for its strength and durability, making it an excellent choice for creating sturdy and long-lasting bags. It is lightweight, resistant to tear and abrasion, and can withstand heavy loads. Additionally, fiberglass fabric is often used in industries where strength and durability are essential, such as aerospace and automotive, further highlighting its suitability for backpacks and luggage. However, it is worth noting that fiberglass fabric may not be as flexible or moldable as other materials, so it may be more suitable for rigid or structured bag designs rather than soft or collapsible styles.

- Q: What is the UV resistance of fiberglass fabric?

- The UV resistance of fiberglass fabric is widely acknowledged as excellent. Due to its composition and structure, fiberglass itself is naturally resistant to damage from ultraviolet (UV) radiation. The glass fibers used in fiberglass fabric are made from silica, which possesses inherent properties of UV resistance. Moreover, during the manufacturing process, the fabric is typically treated with UV-resistant coatings or additives, further augmenting its ability to endure prolonged exposure to sunlight. This remarkable UV resistance renders fiberglass fabric a perfect choice for outdoor applications that entail extended direct sunlight exposure. It finds utility in various industries and applications, such as outdoor furniture, marine applications, automotive parts, and construction materials. The fabric's capacity to withstand UV degradation ensures the preservation of its physical properties and integrity over time, guaranteeing a longer lifespan and enhanced durability. Nevertheless, it is important to acknowledge that although fiberglass fabric exhibits high UV resistance, continuous exposure to intense sunlight may gradually cause some degradation or discoloration over an extended period. Therefore, it is advisable to adhere to proper maintenance and care instructions in order to minimize any potential effects of UV exposure. Regular cleaning, the application of protective coatings, and storing the fabric in shaded areas when not in use can contribute to prolonging its UV resistance and overall lifespan.

- Q: Can fiberglass fabric be used for making molds?

- Indeed, molds can be made using fiberglass fabric. Fiberglass, a versatile material widely utilized in the construction and manufacturing sectors, is renowned for its robustness, longevity, and capacity to assume diverse forms. In the process of mold-making, fiberglass fabric is often overlaid with resin or epoxy to construct a firm and enduring framework. This amalgamation facilitates effortless release of the molded item and imparts a sleek surface. Fiberglass fabric finds utility in a multitude of mold-making endeavors, including the creation of prototypes, sculptures, and even industrial molds.

- Q: Can fiberglass fabric be used for insulation in construction projects?

- Indeed, insulation in construction projects can utilize fiberglass fabric. Constructed from interwoven glass fibers, this material boasts remarkable thermal insulation capabilities. It finds extensive application in walls, roofs, and floors, effectively impeding heat transfer and enhancing energy efficiency within buildings. Its lightweight nature, flexibility, and ease of installation contribute to its widespread adoption in construction endeavors. Moreover, fiberglass fabric's resistance to fire, moisture, and chemicals renders it a sturdy and enduring insulation material.

- Q: How does fiberglass fabric perform in high-pressure applications?

- Fiberglass fabric excels in high-pressure applications due to its exceptional performance. Its inherent strength and durability allow it to withstand high levels of pressure without compromising its structural integrity. The tightly woven fibers of fiberglass fabric provide excellent resistance to stretching, tearing, and bursting, making it a perfect choice for high-pressure environments. One of the major advantages of fiberglass fabric in high-pressure applications is its ability to maintain dimensional stability, even under extreme pressure. Unlike other materials that may deform or lose their shape, fiberglass fabric retains its form and strength, ensuring consistent performance over time. This stability is crucial in industries like aerospace, oil and gas, and automotive, where high-pressure conditions are prevalent. Furthermore, fiberglass fabric exhibits high chemical resistance, making it suitable for applications involving exposure to corrosive substances or harsh environments. It can withstand the effects of various chemicals, acids, solvents, and even extreme temperatures, ensuring its longevity and reliability in high-pressure settings. Additionally, fiberglass fabric offers excellent thermal insulation properties, which can be advantageous in high-pressure applications where temperature control is vital. It effectively resists heat transfer, preventing energy loss and maintaining the desired temperature within the system. In conclusion, fiberglass fabric excels in high-pressure applications due to its strength, dimensional stability, chemical resistance, and thermal insulation properties. Its ability to withstand high levels of pressure without compromising its structure makes it an ideal choice for industries operating in demanding environments.

- Q: Can fiberglass fabric be used for filtration?

- Yes, fiberglass fabric can be used for filtration purposes. Fiberglass fabric is known for its high strength, durability, and resistance to chemicals, making it an ideal material for filtration applications. It is often used in industries such as water treatment, oil and gas, pharmaceuticals, and food processing. Fiberglass fabric can be used as a filter media to remove impurities, solid particles, and contaminants from liquids or gases. Its fine fibers create a dense network that effectively traps and retains particles of various sizes, leading to efficient filtration. One of the main advantages of fiberglass fabric for filtration is its high temperature resistance. It can withstand extreme temperatures, making it suitable for applications where hot or corrosive fluids need to be filtered. Additionally, fiberglass fabric can be customized to meet specific filtration requirements. It can be coated or treated with various substances to enhance its filtration efficiency, improve chemical resistance, or make it water repellent. Overall, fiberglass fabric is a versatile material that can be used effectively for filtration purposes due to its strength, durability, temperature resistance, and customization options.

- Q: What is the resolution of glass fiber cloth and polyester fiber cloth?

- Fiberglass cloth is also commonly called fiberglass geotextile. A geosynthetic material widely used in civil engineering.

Send your message to us

Fiberglass Silicone Fabric for Grinding Wheel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords