Fiberglass Fabric Coated with Silicone Rubber

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Fabric Coated with Silicone Rubber

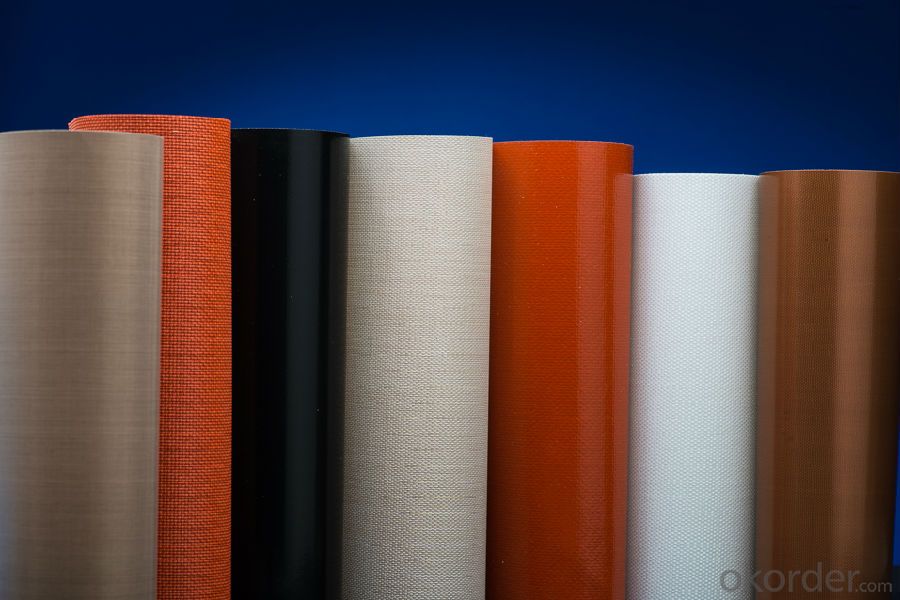

Fiberglass Fabric Description

Silicone coated fiberglass fabricare made of fine fiberglass with excellent capacity of high temperature and corrosion resistance, coated and rolled with silicone rubber, which is a brand new product with good performance and multiple applications.

Fiberglass Fabric Specification

Thickness:0.2mm-5mm

Width:100cm-150cm

Color;grey/red/silver/black

Weight(coating):130gsm-2800gsm

Model No | FSD2030 | FSD2030 | FSD2050 | FSD2100 | |

High temperature resistant(°C) | ≤280 | ≤280 | ≤280 | ≤280 | |

Low temperature resistant(°C) | ≥-40 | ≥-40 | ≥-40 | ≥-40 | |

Tensile intensity (N/50mm) | Warp | ≥1750 | ≥1750 | ≥2500 | ≥3500 |

Weft | ≥1280 | ≥1280 | ≥2100 | ≥3000 | |

Inflating burst intensity(Mpa) | ≥2.0 | ≥2.0 | ≥2.2 | ≥2.6 | |

Peeling intensity(N/m) | ≥450 | ≥450 | ≥520 | ≥600 | |

Insulation (kv/mm) | 16 | 16 | 18 | 18 | |

Weight (g/m*m) | 550-650 | 550-650 | 750-800 | 1500-1800 | |

Width(mm) | 1000±20 | 1000±20 | 1000±20 | 1000±20 | |

Thickness(mm) | 0.3-0.4 | 0.3-0.4 | 0.05-0.55 | 1.0-1.1 | |

color | Silver-gray, gray, red | lucency | Silver-gray, gray, red | Black, gray, red | |

Fiberglass Fabric Features:

1, Good performance on resisting high temperature and low temperature, -40°C-280°C;

2, High strength;

3, Ozone, oxide, light and weather aging resistance;

4, High insulation: dielectric constant:3-3.2, breakdown voltage: 20-50KV/MM;

5, Chemical corrosion resistant, oil-proofing, waterproofing (washable)

Fiberglass Fabric Application:

1) Electric insulation: it feature high grade of electric insulation and bear a load of high voltage. It fits for making products like insulation cloth and sleeves et.

2) Non - metalli compensator: used as pipeline oupling, non-metallic compensactor helps to avoid damage caused by heat expansion and cold contraction. This membrane material speially fit for using in industres of petroleum, chemical engineering, cement, iron and steel and good elasticity and toughness.

3)Anti-conrrosion sector: It is good to be used as inner and outer anti-corrosion layer featuring excellent corrosion resistance, tempareture resistance and high strength. It proves to be an ideal anti-corrosion material.

4) Others: Apart from above application, it can also be used as sealing material, temperature resistant and anti-orrosion conveyr belt and packaging material.

Product Show

FAQ

1.What are the characteristics of fiberglass fabric?

a)Outstanding temperature resistance(from -70°C to +260°C)

b)Excellent chemical resistance

c)Superior non-stick surface, easy to clean

d)High dielectric strength

e)Dimensional stability

f)Resistance to UV, IR and HF

g)Non-toxic

2.How many methods to weave the fabric?

Four methods to weave the fabric:

a).Plain weave: it can be used in electricity insulation materials and reinforced materials in industry, because of inseparable structure, plain and clear lines.

b).Twill weave: compared with plain weave, it is of high density, high intensity, with a soft and loose structural weave. It can be used in ordinary reinforced materials, filter materials, and painting cloth.

3.Can you offer us some samples?

We are willing to offer our customers best product&service,if it's necessary we can send

you sample for test;also we welcome all you customer have a trial order.

- Q:How is fiberglass fabric stored and transported?

- To ensure the protection and preservation of fiberglass fabric, it is customary to store and transport it in a specific manner. The fabric should be kept in a dry and temperature-controlled setting to prevent moisture absorption and the growth of mold. It is common practice to store the fabric rolls vertically on pallets or racks to avoid unnecessary pressure that could cause deformation or damage. Regarding transportation, fiberglass fabric is typically shipped in rolls. These rolls are often wrapped in protective plastic or placed in bags to shield them from dust, dirt, and potential water damage during transit. Additionally, they may be placed in sturdy cardboard boxes or on pallets to provide extra support and prevent any shifting or movement during transportation. It is crucial to handle the fabric rolls with care during transit to prevent tears or damage. This involves securely fastening the rolls in the transportation vehicle using straps or other securing mechanisms to prevent movement and potential harm. In summary, proper storage and transportation of fiberglass fabric involve maintaining an appropriate environment and taking precautions to safeguard the fabric from external elements and physical stress. By adhering to these guidelines, the integrity and quality of the fiberglass fabric can be preserved, ensuring it reaches its destination in optimal condition.

- Q:What are the different weights or thicknesses available for fiberglass fabrics?

- There are various weights or thicknesses available for fiberglass fabrics, ranging from lightweight options like 3 oz per square yard to heavier options like 18 oz per square yard.

- Q:What kind of fiberglass cloth is used for neoprene waterproofing coating?

- Generally can be divided into solvent and emulsion!

- Q:What are the different fiberglass fabric finishes for UV resistance?

- There are several different fiberglass fabric finishes available for UV resistance. These finishes are applied to the surface of the fabric to protect it from the damaging effects of ultraviolet (UV) radiation. Some common fiberglass fabric finishes for UV resistance include: 1. Silicone Coating: This finish provides excellent UV resistance and is often used in applications where high flexibility and heat resistance are required. Silicone-coated fiberglass fabrics are commonly used in industries such as aerospace, automotive, and construction. 2. Acrylic Coating: Acrylic-coated fiberglass fabrics offer good UV resistance and are known for their durability and resistance to abrasion. These finishes are often used in outdoor applications, such as awnings, canopies, and outdoor furniture. 3. PTFE Coating: Polytetrafluoroethylene (PTFE) coatings provide exceptional UV resistance and are known for their non-stick properties. PTFE-coated fiberglass fabrics are commonly used in applications where low friction, high heat resistance, and UV protection are required, such as conveyor belts, release sheets, and insulation covers. 4. PVC Coating: Polyvinyl chloride (PVC) coatings offer good UV resistance and are commonly used in applications where waterproofing and UV protection are required. PVC-coated fiberglass fabrics are often used in outdoor covers, tents, and tarps. 5. Polyurethane Coating: Polyurethane (PU) coatings provide good UV resistance and are known for their flexibility and resistance to chemicals. PU-coated fiberglass fabrics are often used in applications where flexibility, UV protection, and resistance to oils and solvents are required, such as flexible ducting, protective clothing, and inflatable structures. It is important to note that the choice of fiberglass fabric finish for UV resistance depends on the specific requirements of the application. It is recommended to consult with a knowledgeable supplier or manufacturer to determine the most suitable finish for a particular application.

- Q:How does fiberglass fabric perform in abrasive environments?

- Fiberglass fabric has gained a reputation for its exceptional performance in abrasive environments due to its unique composition and construction. This material is made by weaving together fine strands of glass fibers, resulting in a strong and durable fabric. These glass fibers have excellent resistance to abrasion, making the fabric highly resilient and capable of withstanding the repetitive rubbing or scraping actions commonly encountered in abrasive environments. To further enhance its resistance to abrasion, fiberglass fabric is often coated with a protective layer or finish. This protective coating acts as a barrier, preventing direct contact between the fabric and abrasive particles. Consequently, the fabric maintains its integrity and performance over time, even in extremely abrasive conditions. Furthermore, fiberglass fabric exhibits low friction properties, which is particularly advantageous in abrasive environments. This characteristic reduces the likelihood of the fabric being abraded or worn down by constant rubbing or contact with rough surfaces. It also helps to minimize the generation of heat, a common side effect of abrasion, thereby contributing to the fabric's longevity and performance. In summary, fiberglass fabric is an excellent choice for applications in abrasive environments. Its inherent resistance to abrasion, combined with protective coatings and low friction properties, ensures that the fabric can withstand the challenges posed by abrasive conditions, offering long-lasting performance and durability.

- Q:Can fiberglass fabric be used for making insulation gaskets?

- Yes, fiberglass fabric can be used for making insulation gaskets. It is a commonly used material due to its excellent thermal insulation properties and ability to withstand high temperatures. Additionally, fiberglass fabric is resistant to chemical corrosion and has good mechanical strength, making it suitable for creating effective insulation gaskets.

- Q:How does fiberglass fabric perform in tensile strength?

- Fiberglass fabric is highly regarded for its impressive performance in terms of tensile strength. Tensile strength refers to a material's ability to withstand tension without breaking or deforming, and fiberglass fabric excels in this aspect. The strength of fiberglass fabric can be attributed to its composition, which consists of finely woven glass fibers. These fibers possess exceptional tensile strength, resulting in a strong and durable fabric. This makes fiberglass fabric ideal for applications that require resistance against pulling forces. Additionally, fiberglass fabric offers a high tensile strength-to-weight ratio, allowing it to withstand substantial amounts of tension without adding excessive weight to the structure. This characteristic is particularly advantageous in industries such as aerospace, automotive, construction, and marine, where lightweight yet sturdy materials are essential. Furthermore, fiberglass fabric maintains its tensile strength even when exposed to harsh environmental conditions, including extreme temperatures, moisture, and chemicals. This reliability makes it a preferred choice for applications that demand stability and longevity. It is important to note that the specific manufacturing process and type of glass fibers used can affect the tensile strength of fiberglass fabric. However, overall, fiberglass fabric is renowned for its exceptional tensile strength performance, making it highly favored in various industries and applications.

- Q:Is fiberglass fabric resistant to chemicals in swimming pools?

- Yes, fiberglass fabric is generally resistant to chemicals used in swimming pools. Fiberglass is a robust and durable material that is commonly used in the construction of swimming pools due to its excellent chemical resistance. It can withstand the corrosive effects of chlorine, bromine, and other chemicals commonly used to treat pool water. This resistance allows fiberglass fabric to maintain its structural integrity and appearance, making it an ideal choice for pool linings, covers, and other applications where exposure to pool chemicals is expected. However, it is essential to note that prolonged exposure to highly concentrated or extremely harsh chemicals may eventually cause some degradation or discoloration of the fiberglass fabric. Therefore, regular maintenance and proper care are necessary to ensure the longevity and performance of fiberglass fabric in swimming pool environments.

- Q:Can fiberglass fabric be dyed?

- Yes, fiberglass fabric can be dyed.

- Q:Is fiberglass fabric resistant to chemicals used in wastewater treatment?

- Fiberglass fabric exhibits remarkable resistance to the chemicals employed in wastewater treatment. Its outstanding chemical resistance has earned fiberglass a reputation as an optimal material for scenarios where exposure to diverse chemicals is probable. It has the capacity to endure a broad spectrum of corrosive substances, such as acids, alkalis, and solvents, commonly encountered in wastewater treatment processes. Due to the non-reactive quality of fiberglass fabric, it remains unaffected and undamaged when exposed to these chemicals, making it a dependable choice for implementation in wastewater treatment facilities. Additionally, fiberglass fabric also offers resistance to UV radiation, moisture, and fluctuations in temperature, which further bolsters its durability and suitability for such environments.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Fabric Coated with Silicone Rubber

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords