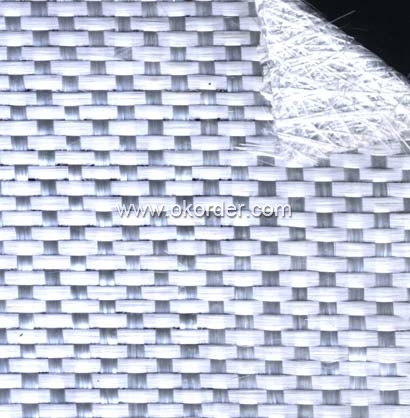

Fiberglass Fabrics Stitch Combo Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- One Pallet kg

- Supply Capability:

- 20 days for 1 x 20FCL kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application of Fiberglass Stitch Combo Mat

Name: | E-Glass Stitch Combo Mats |

Lead Time: | 20 days for 1 x 20FCL |

MinOrder: | One Pallet |

Package: | Plastic Bag, Carton and Pallet |

Characteristic of Fiberglass Stitch Combo Mat

The special product construction where 0°,90°rovings are parallel aligned without crossing facilities resin impregnation in the layers of chopped strands, resulting in higher productivity and reduced consumption of resins.

The multi-layer structure delivers increased area weight and simplifies the manufacturing process of the composite products, resulting in improve molding productivity and reduced cost.

The composite products feature multi-directional and balanced mechanical properties.

Package of Fiberglass Stitch Combo Mat

Each stitch combo mat is wounded onto a paper tube which has an inside diameter of 73mm, and the roll has a diameter of 260mm. The roll is wrapped up with plastic film, and then packed in a cardboard box or wrapped up with kraft paper. The rolls are to be horizontally placed. For transporation the rolls can be loaded into a container directly or on pallets.

Storage of Fiberglass Stitch Combo Mat

Unless otherwise specified, fiberglass products should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃-35℃ and 35%-65% respectively.

Standard:ISO 9001

- Q: What are the different thicknesses of fiberglass fabric available?

- A variety of thicknesses of fiberglass fabric are offered to meet different needs and uses. Fiberglass fabric is typically measured in ounces per square yard (oz/yd^2). The most commonly used thicknesses range from 4 oz/yd^2 to 10 oz/yd^2, with increments of 2 oz/yd^2. For applications requiring a thin and flexible material, such as repairs on small boats or automotive parts, 4 oz/yd^2 fiberglass fabric is commonly chosen as it is relatively lightweight. A medium-weight option, 6 oz/yd^2 fiberglass fabric, provides better strength and durability compared to the 4 oz/yd^2 option. It is often used for general repairs, reinforcing weak areas, or constructing lightweight structures. For increased strength and rigidity, the 8 oz/yd^2 fiberglass fabric is a heavier option. It is commonly used for more demanding applications like reinforcing large structural components or manufacturing composite parts. When maximum strength and durability are required, the thickest commonly available option, 10 oz/yd^2 fiberglass fabric, is chosen. It is often used for industrial purposes like reinforcing concrete structures or manufacturing high-performance composite materials. Aside from these common thicknesses, there are specialty fiberglass fabrics available that can be much thicker or thinner depending on the specific application. It is crucial to select the appropriate thickness of fiberglass fabric based on the intended use to ensure optimal performance and desired outcomes.

- Q: Can fiberglass fabric be used for insulation in silos?

- Yes, fiberglass fabric can be used for insulation in silos. Fiberglass fabric is known for its excellent thermal insulation properties, making it suitable for insulating silos and maintaining optimal temperature levels inside.

- Q: Can fiberglass fabric be used for reinforcement in 3D printing?

- Yes, fiberglass fabric can be used for reinforcement in 3D printing. It is commonly used to add strength and durability to printed objects, especially those that require enhanced mechanical properties. The fiberglass fabric can be embedded within the printed layers to provide reinforcement and improve the overall structural integrity of the printed part.

- Q: How does fiberglass fabric handle moisture?

- Fiberglass fabric is highly resistant to moisture. It doesn't absorb water and is not prone to mold or mildew growth. It maintains its strength and durability even when exposed to high levels of humidity or wet conditions.

- Q: Can fiberglass fabric be used for making backpacks?

- Yes, fiberglass fabric can be used for making backpacks. Fiberglass fabric is a strong and durable material that is known for its resistance to heat, chemicals, and abrasion. It is also lightweight and has good tensile strength, making it suitable for backpacks. Additionally, fiberglass fabric is often used in industries such as aerospace, automotive, and marine due to its high strength-to-weight ratio. However, it is important to note that fiberglass fabric can be rigid and stiff, which may affect the overall comfort and flexibility of the backpack. Therefore, it is essential to consider the specific requirements and preferences of the backpack user before using fiberglass fabric for making backpacks.

- Q: How is fiberglass fabric used in the production of sports helmets?

- Due to its unique properties, fiberglass fabric is widely used in the manufacturing of sports helmets. Its strength and durability are well-known, providing excellent impact resistance to protect the head during sports activities that involve collisions and falls. The production process involves several steps. To achieve the desired helmet shape, the fiberglass fabric is layered and molded using a combination of heat and pressure. This allows the fabric to conform precisely to the specific contours and curves required for a comfortable and secure fit. In addition, fiberglass fabric is lightweight, making it an excellent choice for sports helmets. It does not add unnecessary weight to the user's head, ensuring comfort and reducing fatigue during extended use. Its lightweight nature also allows for greater maneuverability and agility, which is especially important in fast-paced sports. Another significant advantage of fiberglass fabric in sports helmets is its resistance to water and moisture. This ensures that the helmet remains intact and functional even in wet conditions, such as during water sports or heavy sweating. Moreover, fiberglass fabric is resistant to UV radiation, preventing degradation and maintaining the helmet's structural integrity over time. Lastly, fiberglass fabric offers customization and design flexibility. It can be easily combined with other materials or coatings to enhance specific features of the helmet, such as adding an extra layer of protection or improving its aerodynamics. In conclusion, fiberglass fabric is an essential component in the production of sports helmets due to its strength, durability, lightweight nature, resistance to water and UV radiation, and design flexibility. It plays a crucial role in ensuring the safety and comfort of athletes participating in various sports activities.

- Q: Is fiberglass fabric easy to work with?

- Yes, fiberglass fabric is generally easy to work with. It is lightweight, flexible, and can be easily cut, molded, and shaped to fit various surfaces and structures. Additionally, it is resistant to heat, chemicals, and corrosion, making it a popular choice for a wide range of applications such as insulation, reinforcement, and composite materials.

- Q: Can fiberglass fabric be used for insulation in telecommunications cables?

- Fiberglass fabric is indeed suitable for insulation in telecommunications cables. This fabric possesses exceptional thermal insulation properties, rendering it an optimal selection for the insulation of cables that carry electrical signals. Furthermore, it can endure high temperatures and exhibits resistance against fire, chemicals, and abrasion. Consequently, it provides a dependable and long-lasting solution for the insulation needs of telecommunications cables. Moreover, fiberglass fabric is lightweight, flexible, and easily manageable, which facilitates the installation and maintenance of cables. Its elevated dielectric strength guarantees the absence of interference with the electrical signals transmitted through the cables. Accordingly, fiberglass fabric is commonly employed as an insulation material in telecommunications cables, ensuring the protection of the cables and facilitating efficient and reliable signal transmission.

- Q: How to distinguish carbon fishing rod?

- Carbon poles have electricity proof signs, glass steel poles do not have.

- Q: Latex paint cracking, how to deal with latex paint cracking what are the reasons?

- Chenguang nano silver high efficiency antibacterial interior wall latex paint, healthy and environmental protection, resistant to dirt, weather resistance, good quality. In the process of repairing, etc. to each paint all dried up to the next coat, so as to ensure that the latex paint appear Konggu off in later stage.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 1969 |

| Annual Output Value | Above US$ 150 Million |

| Main Markets | overseas companies in Hongkong, Canada, South Africa, South Korea, India, Italy, Singapore, France and many other countries and regions. |

| Company Certifications | ISO9001;ISO14001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 40%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English |

| b) Factory Information | |

| Factory Size: | Above 5000,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | |

| Product Price Range | Average |

Send your message to us

Fiberglass Fabrics Stitch Combo Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- One Pallet kg

- Supply Capability:

- 20 days for 1 x 20FCL kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords