Teflon Fiberglass Fabric Stitched Combo Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 12000 kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

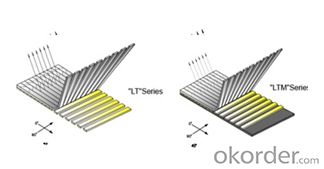

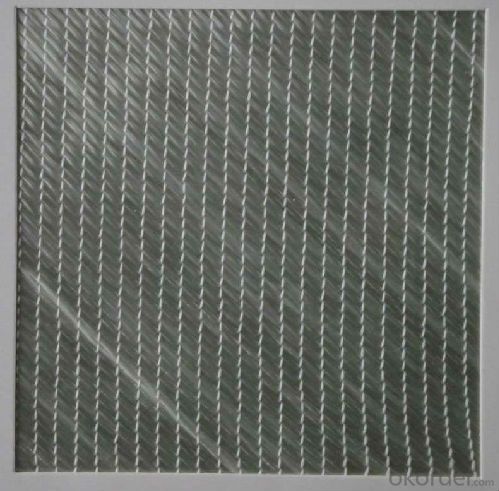

(0°/90°) series mat:

Two layers of roving(550g/㎡-1250g/㎡) are aligned at 0°/90° with or without a layer of chopped strands(0g/㎡-500g/㎡)。The product has a maximum width of 100 inches.This product can be used for manufacturing boats,cases and shell of car.

2.Product Structure

3.Product Specifications

Product No. | Overall Density | .0° Roving Density | .90° Roving Density | Chop Density | Polyester Yarn Density |

(g/m2) | (g/m2) | (g/m2) | (g/m2) | (g/m2) | |

E-LTMC1603 | 671.74 | 303.8 | 247.96 | 101.62 | 18.36 |

E-LTMC1608 | 844.76 | 303.8 | 247.96 | 274.64 | 18.36 |

E-LTMC1808 | 903.8 | 303.8 | 307 | 274.64 | 18.36 |

E-LTMC1810 | 934.31 | 303.8 | 307 | 305.15 | 18.36 |

E-LTMC1815 | 1086.89 | 303.8 | 307 | 457.73 | 18.36 |

E-LTMC2408 | 1101.04 | 405.66 | 401.46 | 274.64 | 19.28 |

E-LTMC2415 | 1284.13 | 405.66 | 401.46 | 457.73 | 19.28 |

E-LTMC3205 | 1272.69 | 607.6 | 491.86 | 152.58 | 20.65 |

E-LTMC3205-HS | 1388.43 | 607.6 | 607.6 | 152.58 | 20.65 |

E-LTMC3208 | 1394.75 | 607.6 | 491.86 | 274.64 | 20.65 |

E-LTMC3610 | 1541 | 607.6 | 607.6 | 305.15 | 20.65 |

Special specification can be produce according to customer requirements.

4.FAQ

Packaging:

Each roll is wound onto a paper tube which has an inside diameter of 76mm and the roll has a diameter of 275mm. The roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: How strong is fiberglass fabric?

- Known for its exceptional strength and durability, fiberglass fabric is composed of woven glass fibers, resulting in a material that is both strong and flexible. The strength of the fabric can vary depending on factors such as the density of the weave and the specific type of glass used. Compared to traditional fabrics like cotton or polyester, fiberglass fabric is generally considered to be stronger. It possesses high tensile strength, meaning it can withstand significant pulling or stretching forces without breaking or tearing. Additionally, fiberglass fabric is highly resistant to heat, chemicals, and UV radiation, making it suitable for a wide range of applications. Due to its renowned strength, fiberglass fabric is the preferred choice in various industries including construction, automotive, aerospace, and marine.

- Q: How is fiberglass fabric cleaned?

- Fiberglass fabric can be cleaned by first removing any loose debris or dirt with a soft brush or vacuum cleaner. Then, mix a mild detergent with warm water and gently scrub the fabric using a sponge or soft cloth. Rinse thoroughly with clean water and allow it to air dry. Avoid using harsh chemicals or abrasive materials that may damage the fiberglass fabric.

- Q: Can fiberglass fabric be used for insulation in pharmaceutical facilities?

- Yes, fiberglass fabric can be used for insulation in pharmaceutical facilities. It is a commonly used material due to its excellent thermal insulation properties, fire resistance, and ability to withstand high temperatures. Additionally, it is lightweight, durable, and cost-effective, making it suitable for various applications in pharmaceutical facilities.

- Q: What is the dimensional stability of fiberglass fabric?

- Fiberglass fabric possesses remarkable dimensional stability, which is characterized by its capacity to sustain its shape and size without substantial stretching, shrinking, or warping in diverse circumstances. This outstanding dimensional stability is primarily attributed to the composition of fine glass fibers that are interlaced to create a taut and uniform structure. The glass fibers employed in fiberglass fabric demonstrate a high tensile strength, rendering them resistant to elongation or stretching. Consequently, the fabric remains true to its original dimensions even when subjected to mechanical stress or tension. Moreover, the glass fibers exhibit a low coefficient of thermal expansion, signifying minimal expansion or contraction in response to temperature fluctuations. This thermal stability greatly contributes to the fabric's ability to uphold its shape and size across a wide range of temperatures. Additionally, fiberglass fabric exhibits exceptional resistance to moisture absorption and chemical degradation. Unlike many other fabrics, fiberglass fabric repels water, thereby preventing significant absorption and subsequent dimensional alterations caused by moisture. Furthermore, the chemically inert nature of the glass fibers ensures resistance to most chemicals, safeguarding the fabric against chemical degradation that may compromise its dimensional stability. In conclusion, fiberglass fabric possesses excellent dimensional stability, making it a preferred choice in numerous industries such as aerospace, automotive, construction, and marine. Its capacity to maintain its shape, size, and structural integrity under diverse conditions renders it suitable for applications that demand consistent and dependable performance.

- Q: How does fiberglass fabric perform in peel strength?

- Fiberglass fabric typically performs well in peel strength due to its strong and durable nature. It exhibits good resistance to delamination or separation under applied forces, making it a reliable choice for applications where peel strength is important, such as in composite materials, automotive parts, and aerospace components.

- Q: Are fiberglass fabrics resistant to water absorption?

- Fiberglass fabrics, in general, show resistance to water absorption. The non-porous nature of fiberglass prevents easy passage of water, making it highly resistant to water absorption. To enhance this resistance, fiberglass used in fabrics is often coated with a water-resistant finish or treated with chemicals. This quality makes fiberglass fabrics suitable for various applications that require water resistance, including outdoor clothing, marine equipment, and waterproofing materials. It is important to note, however, that although fiberglass fabrics resist water absorption, they may not be entirely waterproof. In extreme conditions, such as prolonged heavy rain or submersion in water, some water may eventually permeate through the fabric.

- Q: Is fiberglass fabric suitable for use in aerospace interiors?

- Yes, fiberglass fabric is suitable for use in aerospace interiors. Fiberglass fabric is known for its excellent strength-to-weight ratio and fire resistance, making it an ideal material for various applications in the aerospace industry. It is commonly used in the construction of aircraft interiors, including walls, ceilings, seats, and insulation. One of the primary reasons fiberglass fabric is preferred in aerospace interiors is its high strength. It offers exceptional durability and can withstand the rigorous conditions and vibrations experienced during flights. Additionally, its lightweight nature helps reduce the overall weight of the aircraft, resulting in improved fuel efficiency. Moreover, fiberglass fabric is inherently fire-resistant, which is crucial for ensuring the safety of passengers and crew members. In the event of a fire, fiberglass fabric will not ignite or contribute to the spread of flames, providing valuable time for evacuation and minimizing the risk of a catastrophic incident. Furthermore, fiberglass fabric is highly versatile and can be easily molded and shaped to fit the specific design requirements of aerospace interiors. It can be used as a structural material, providing stiffness and support, or as a decorative element, enhancing the aesthetic appeal of the cabin. In summary, fiberglass fabric offers numerous advantages that make it suitable for use in aerospace interiors. Its strength, lightweight nature, fire resistance, and versatility make it an excellent choice for ensuring the safety, durability, and functionality of aircraft cabins.

- Q: Can fiberglass fabric be used for insulation in cryogenic applications?

- Fiberglass fabric is suitable for insulation in cryogenic applications because of its exceptional insulating properties. These properties enable it to effectively trap air pockets within its structure, reducing heat transfer. Consequently, it is ideal for maintaining extremely low temperatures in cryogenic environments. Moreover, fiberglass is a non-flammable material that plays a crucial role in ensuring safety in cryogenic settings. Its resistance to moisture and chemicals further enhances its suitability for cryogenic insulation. Nevertheless, it is vital to carefully choose the specific type of fiberglass fabric for cryogenic applications. There are various grades and thicknesses available, and the selection should be based on the specific requirements of the cryogenic application to achieve optimal insulation performance. In conclusion, fiberglass fabric's excellent insulating properties, non-flammability, and resistance to moisture and chemicals make it suitable for insulation in cryogenic applications. However, it is essential to select the appropriate type of fiberglass fabric to ensure optimal insulation performance in cryogenic environments.

- Q: What is the moisture resistance of fiberglass fabric?

- Fiberglass fabric has high moisture resistance due to its inherent non-absorbent nature and the hydrophobic properties of the fiberglass material.

- Q: Can fiberglass fabric be used for banners and signs?

- Certainly! Banners and signs can indeed make use of fiberglass fabric. This versatile material provides numerous advantages in this regard. Its durability, lightweight nature, and resistance to various weather conditions render it fitting for both indoor and outdoor purposes. Furthermore, fiberglass fabric boasts a sleek surface that allows for top-notch printing and vivid colors. It also proves effortless to maneuver and can be readily mounted or hung. Ultimately, employing fiberglass fabric for banners and signs guarantees prolonged lifespan and aesthetic allure, explaining why countless businesses and organizations favor it.

Send your message to us

Teflon Fiberglass Fabric Stitched Combo Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 12000 kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords