Sewing Fiberglass Fabric FRP Pultrusion Roof Tile Sheets or Panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500M2 m²

- Supply Capability:

- 900M2/Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FRP Pultrusion Roof Tile Sheets or Panels

Description

In general, our company specializes in FRP grating, FRP decking, FRP platform and other products of FRP. We have a varity of FRP products sold over the country because we have our own teams of design, manufacturing and sales with hundreds of staffs.

At the same time, we are devoted to creating a production and marketing for FRP products, which has certain influence in China by proceeding with professional teams, rigorous quality management system and advanced production facility.

Today, we’re planning to win more market shares in the world and let more customers know us.

Photos

Product Traits

1. Corrosion resistance no rust, no maintenance, long service life.

2. Lightweight, high strength pultrusion process molding FRP profiles have high glass fiber content (60%). In this situation, the density of glass fiber reinforced plastic is only about a quarter of the steel.

3. The intensity and stiffness is quite prominent,.

4. Anti-fatigue high anti- fatigue strength, allowing repeated bending without permanent deformation.

5. Anti-aging select highquality FRP pultrusion profiles, the service life of the product can be more than 20 years.

6. Anti-UV agent are added into all pultrusion FRP profiles get the best anti-uv effect.

Product Advantage

Coated with prevent aging layer

Excellent insulating performance

Easy to maintain.

High strength.

Long service life.

Easy to install.

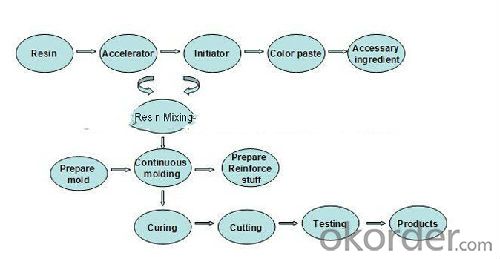

Production Process

Specification

Mechanical properties: high rigidity lighting panels

Plate matches: match with general prepainted galvanized sheet, galvanized steel

Resin composites: Improved anti-aging SMR198 resin

Fiber reinforcement: E-glass fiber untwisted without glue

Surface treatment: affixing MELINEX301 film

Stiffener line: surface with longitudinal uniform distribution of anti-LAC gluten

Glass fiber: not less than 28%

Unit Weight: 1800g / ㎡, 2400g / ㎡, 3050g / ㎡

Nominal thickness: 1.2 mm, 1.5mm, 2.0mm (tolerance ≤ 10%)

Temperature limits: -60 ℃ ~ +130 ℃

Transmittance (1.5mm): 72% ± 2% (fog white, sky blue, water green), 52% ± 2% (white porcelain)

UV-rate: 99%

Tensile strength: 90Mpa

Flexural strength: 160 Mpa

Elongation: 1.9%

Pap hardness: ≥ 50

Thermal expansion coefficient: 1.5 ~ 3.2 * 10-5 / K

Thermal conductivity: K = 0.23W / m * K

Guarantee: 15 years

NOTE: In special cases, the surface film varieties vary according to needs, such as Melinex389, PT055 and so on

FAQ

1.Which country do you mainly export to?

A: Our products are very popular in Mid East, India, South East Asia, Latin America, Africa.

2.Q: What’s the advantage of you compared with other suppliers experienced in foreign trade?

A: We have been specialized in FRP products for over decades years and approved by many domestic companies. Except for our quality and price, we’re also able to give you the best service.

3.Q:Can you provide some samples?

A: Yes, of course. We will send you samples for your confirmation before you place firm orders.

- Q: Can fiberglass fabric be used for making curtains or drapes?

- Yes, fiberglass fabric can be used for making curtains or drapes. Fiberglass fabric is known for being lightweight, durable, and resistant to heat, moisture, and chemicals. These properties make it suitable for various applications, including curtains and drapes. Fiberglass fabric can provide insulation, reduce heat transfer, and block out sunlight, making it an excellent choice for curtains or drapes in homes, offices, or other spaces. Additionally, fiberglass fabric is available in a range of colors and designs, allowing for customization and versatility in creating curtains or drapes that match any interior decor.

- Q: How is fiberglass fabric used in the manufacturing of sports equipment?

- Fiberglass fabric is commonly used in the manufacturing of sports equipment due to its lightweight and high-strength properties. It is often used as a reinforcement material in the construction of various sports equipment such as surfboards, skis, hockey sticks, and kayaks. The fabric is typically combined with resin and molded into the desired shape, providing enhanced strength, durability, and flexibility to the final product.

- Q: Can fiberglass fabrics be used for reinforcement in composites?

- Yes, fiberglass fabrics can be used for reinforcement in composites.

- Q: What are the different fiberglass fabric coatings for oil resistance?

- There are several different fiberglass fabric coatings that provide oil resistance. Some common options include silicone coatings, neoprene coatings, polyurethane coatings, and PTFE (Teflon) coatings. Each coating has its own unique properties and level of oil resistance, so the choice depends on the specific requirements of the application.

- Q: Home improvement how to do waterproof acceptance?

- For all other fields of moisture-proof and waterproof requirements of lightweight wall wall must be waterproof, waterproof treatment of the wall height should not be lower than 1.8m; the wall bottom should do C20 fine stone concrete wall wall pad, pad high floor is not less than 100mm. This is the most basic lightweight wall waterproofing requirements. For the acceptance of light wall waterproof construction, water spraying test shall be adopted. That is, the use of water pipes in the waterproof paint wall, from top to bottom continuous spraying 3, 4 minutes, the wall of the other side of the impermeable phenomenon can be checked and accepted.

- Q: How is fiberglass fabric coated?

- Different methods are used to coat fiberglass fabric, depending on its intended use and specific requirements. One commonly used method is resin coating, where a liquid resin is applied to the fabric. The resin can be either epoxy or polyester based and is usually mixed with a catalyst to start the curing process. The fabric is then soaked with the resin and excess resin is removed to ensure an even coat. Another method is silicone coating, where a layer of liquid silicone is applied to the fabric. Silicone coatings provide excellent heat resistance and flexibility, making them suitable for insulation or protective covers. Occasionally, fiberglass fabric may be coated with other materials like polyurethane or PTFE (polytetrafluoroethylene), commonly known as Teflon. Polyurethane coatings offer improved abrasion resistance and flexibility, while PTFE coatings provide excellent non-stick properties and high temperature resistance. The coating process can be done using different techniques, including dip coating, spray coating, or roller coating. Dip coating involves immersing the fabric into a tank filled with the coating material, while spray coating evenly distributes the coating onto the fabric surface using a spray gun. Roller coating applies the coating in a controlled manner by passing the fabric through a set of rollers. Overall, the coating process is essential for enhancing the performance and durability of fiberglass fabric, allowing it to be utilized in various industries such as aerospace, automotive, construction, and marine.

- Q: How is fiberglass fabric printed?

- Fiberglass fabric is typically printed using a process called screen printing. In this method, a mesh screen is used to transfer ink onto the fabric, creating the desired design or pattern. The screen is prepared by blocking out areas that are not to be printed, and then ink is pushed through the screen onto the fabric using a squeegee. This allows for precise and durable printing on fiberglass fabric.

- Q: Can fiberglass fabric be used for making automotive interiors?

- Yes, fiberglass fabric can be used for making automotive interiors. Fiberglass fabric is known for its strength, durability, and lightweight properties, making it an ideal material for various applications in the automotive industry. In automotive interiors, fiberglass fabric can be used for making seat covers, door panels, headliners, and various other components. It provides excellent resistance to wear and tear, is easy to clean, and offers a sleek and modern look. Additionally, fiberglass fabric can be molded into different shapes and sizes, allowing for customization and precise fitment in automotive interiors. Overall, fiberglass fabric is a versatile and reliable material choice for enhancing the aesthetics and functionality of automotive interiors.

- Q: Can fiberglass fabric be used for making insulation blankets?

- Yes, fiberglass fabric can be used for making insulation blankets. Fiberglass fabric is known for its excellent thermal insulation properties, making it an ideal material for creating insulation blankets. These blankets are designed to trap heat and prevent its transfer, providing effective insulation in various applications such as in homes, industrial settings, and even in aerospace and automotive industries. The fiberglass fabric used in insulation blankets is typically woven or knitted, allowing it to be flexible and easily molded to fit different shapes and sizes. Additionally, fiberglass fabric is lightweight, fire-resistant, and resistant to chemicals and moisture, making it a reliable choice for insulation applications.

- Q: What is the weight of fiberglass fabric?

- The weight of fiberglass fabric can vary depending on the specific type and thickness of the fabric. Generally, fiberglass fabric is measured in ounces per square yard (oz/yd2) or grams per square meter (g/m2). Common weights for fiberglass fabric range from 0.5 oz/yd2 (17 g/m2) to 3.0 oz/yd2 (102 g/m2) or more. Lightweight fiberglass fabrics are often used for applications such as reinforcing and laminating, while heavier fabrics are commonly used for structural reinforcement or insulation purposes.

Send your message to us

Sewing Fiberglass Fabric FRP Pultrusion Roof Tile Sheets or Panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500M2 m²

- Supply Capability:

- 900M2/Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords