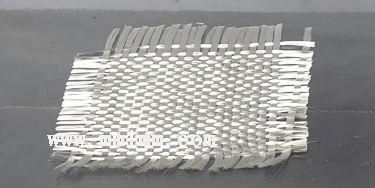

Fiberglass Laminated Scrims Mesh Fabric - Hisilica Fiber Cloth 2024

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Place of Origin: | Brand Name: | Model Number: | |||

| Weight: | Width: | Yarn Type: | |||

| Alkali Content: | Standing Temperature: | Weave: | |||

| Available treatmetn: |

Packaging & Delivery

| Packaging Detail: | Cartons |

| Delivery Detail: | 15-20days |

Specifications

Working temp.:2000F(1100C)

Width: 910mm

Thickness:0.65/1.2/1.35mm

Application:Heat preservation,firefighting,filtration

- Q: Can fiberglass fabric be used for reinforcement in aerospace structures?

- Aerospace structures can utilize fiberglass fabric as a reinforcement material. Fiberglass, known for its lightweight and high-strength properties, possesses excellent mechanical characteristics including high tensile strength and stiffness. It also exhibits a low coefficient of thermal expansion, which is beneficial in aerospace scenarios where temperature changes are likely. In composite structures, fiberglass fabric is commonly used as reinforcement, often combined with a resin matrix like epoxy or polyester. The fabric is impregnated with resin and then cured to form a rigid composite material. This material is employed in the production of various aerospace components such as aircraft wings, fuselage panels, and engine parts. An advantage of using fiberglass fabric as reinforcement in aerospace is its impressive resistance to corrosion. Unlike metals, fiberglass does not rust or corrode, making it suitable for harsh environments encountered during high-altitude flights or exposure to extreme weather conditions. Additionally, fiberglass is non-conductive, which is advantageous for aerospace structures requiring electrical insulation. Furthermore, fiberglass fabric is relatively cost-effective compared to other reinforcement materials like carbon fiber. This makes it an appealing choice for aerospace manufacturers striving for a balance between performance and cost efficiency. However, it is crucial to consider the specific application and requirements of the aerospace structure when selecting the appropriate reinforcement material. While fiberglass fabric offers numerous advantages, certain applications may demand even greater strength or specific properties better provided by other materials.

- Q: Can fiberglass fabric be used for making bookbinding material?

- Yes, fiberglass fabric can be used for making bookbinding material. It is a durable and flexible material that can provide strength and protection to book covers, especially for heavy-duty or long-lasting books. Its resistance to tearing and moisture makes it suitable for bookbinding applications.

- Q: How is fiberglass fabric used in the chemical industry?

- Fiberglass fabric finds numerous applications in the chemical industry due to its exceptional properties and versatility. One of the primary uses of fiberglass fabric is in corrosion-resistant applications. Fiberglass fabric is highly resistant to chemical attack, making it an ideal material for lining tanks, pipes, and other equipment that handle corrosive chemicals. It can withstand exposure to a wide range of chemicals, including acids, alkalis, solvents, and various organic compounds. Furthermore, fiberglass fabric is utilized in the construction of storage tanks for hazardous chemicals. These tanks are often reinforced with multiple layers of fiberglass fabric to provide structural integrity and prevent leakage. The fabric's high tensile strength and excellent dimensional stability make it an excellent choice for such applications. In addition, fiberglass fabric is used in manufacturing chemical filters and membranes. These filters and membranes are designed to separate and purify different chemical compounds. Fiberglass fabric's high porosity allows for efficient flow rates while retaining solid particles and impurities. Its resistance to chemical degradation ensures long-term durability and reliability. Moreover, fiberglass fabric is employed as a protective barrier in the chemical industry. It is used to create curtains, blankets, and covers that shield workers, equipment, and surroundings from potential chemical spills or splashes. These protective barriers act as a reliable shield against hazardous substances, preventing accidents and minimizing the risk of chemical exposure. Overall, fiberglass fabric plays a vital role in the chemical industry by providing corrosion resistance, structural reinforcement, filtration capabilities, and protection against chemical hazards. Its unique combination of properties makes it an indispensable material in various chemical processes, ensuring safety, efficiency, and longevity in chemical operations.

- Q: Can fiberglass fabric be used for roofing?

- Certainly! Roofing applications can indeed utilize fiberglass fabric due to its lightweight and durable nature. This material, widely used in the construction industry, is renowned for its robustness and resistance to corrosion, making it an appropriate choice. By reinforcing roofing systems, fiberglass fabric enhances their strength and stability. It is commonly combined with other materials like asphalt or rubber to create a more resilient and enduring roof. Furthermore, the fire-resistant property of fiberglass fabric ensures an added layer of safety for the roofing system. In summary, fiberglass fabric proves to be a trustworthy and cost-effective alternative for roofing projects.

- Q: Can fiberglass fabric be used for making insulation tapes?

- Yes, fiberglass fabric can be used for making insulation tapes. It is a commonly used material for insulation due to its high thermal resistance and ability to withstand high temperatures. Its durability and flexibility make it suitable for creating tapes used in various insulation applications.

- Q: How much glass fiber cloth and how much epoxy resin does it take to make a square meter of fiberglass?

- There is a construction personnel operation, proficient and skilled, professional and non professional will is much better. I suggest you try it yourself, it will be better.

- Q: How is fiberglass fabric recycled?

- Fiberglass fabric is typically recycled by first separating it from other materials, such as resin or other coatings, through a mechanical process. The separated fabric is then shredded or chopped into small pieces. These pieces are then melted down and processed to remove any impurities. The resulting molten fiberglass is then spun into new fibers or formed into new products, such as insulation or composite materials.

- Q: What are the different weaves available for fiberglass fabric?

- There are several different weaves available for fiberglass fabric, each with its own unique characteristics and uses. Some of the most common weaves include plain weave, twill weave, satin weave, and leno weave. Plain weave is the simplest and most common weave used for fiberglass fabric. It is characterized by an equal number of warp and weft yarns crossing over and under each other in a simple over-under pattern. This weave creates a strong and balanced fabric with good stability and durability. Twill weave is another popular option for fiberglass fabric. In this weave, the warp and weft yarns cross over and under each other in a diagonal pattern, creating a distinctive diagonal ribbing effect. Twill weave provides better drapability and flexibility compared to plain weave, making it suitable for applications that require greater conformability. Satin weave is a more complex weave that produces a smooth and shiny surface on the fabric. It is characterized by long floats of the warp or weft yarns, which means that fewer yarns are interlaced, resulting in a more flexible and lightweight fabric. Satin weave is often used in applications where a high-quality appearance and a soft feel are desired, such as in the production of clothing or decorative fabrics. Leno weave is a unique weave that involves twisting adjacent warp yarns around each other to create a stable and open mesh structure. This weave is commonly used for fiberglass fabrics that require high transparency and breathability, as well as for applications that involve filtration or reinforcement purposes. Overall, the choice of weave for fiberglass fabric depends on the specific requirements of the application. By considering factors such as strength, flexibility, appearance, and breathability, one can select the most suitable weave to achieve optimal performance in their desired application.

- Q: How is fiberglass fabric used in the production of geotextiles?

- Fiberglass fabric is used in the production of geotextiles as a reinforcement material. It provides strength and stability to the geotextile, enabling it to withstand high tensile forces and enhance its durability. The fiberglass fabric is typically incorporated into the geotextile through lamination or needle-punching techniques, creating a composite material that can effectively prevent soil erosion, reinforce slopes, and provide separation and filtration functions in various civil engineering applications.

- Q: What is an electroplated glass fabric?

- Glass fiber mesh in the process of use:The lap width between the mesh is not less than 50mm, the negative corner mesh to pressure stubble lap, its width is larger than 50mm, yang angle is greater than or equal to 200mm. In the construction, mesh paving should be smooth, no wrinkles, mortar plumpness reached 100%, at the same time to find and maintain smooth, straight corner square and the verticality of yin and yang.

Send your message to us

Fiberglass Laminated Scrims Mesh Fabric - Hisilica Fiber Cloth 2024

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords