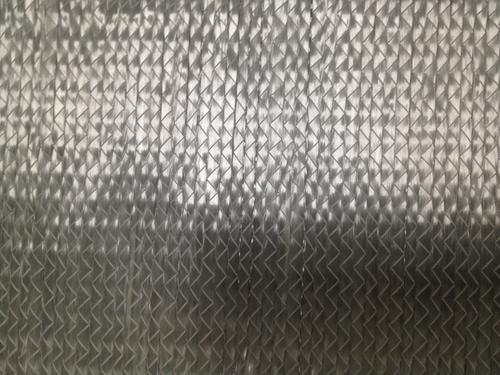

E-GLASS STITCH COMBO MAT- QX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction: E-glass stitched combo mat consists of two or more layers of fiberglass roving which are stitch-bonded.One layer of rovings and different layers of roving can be oriented differently and have different liner density.The roving specification,number of roving layers,mat width and roll diameter can be customized as per requirement. |

Multi-axial series: At most 4 layers of roving can be stitched;however a layer of chopped strands(0g/㎡-500g/㎡)or composite materials can be added.The maximal width can be too inched.This product is used in blades of wind power turbines,boat manufacturing and sports devices. |

Characteristics

1. Manufactured by own factory

2. Good wet-out in resins

3. Good strand dispersion and uniform area weight.

Specification

4 QX 0°/+45°/90°/-45° Quadraxial |

Product No. | Overall Density | 0°Roving Density(g/㎡) | +45°Roving Density (g/㎡) | 90°Roving Density(g/㎡) | -45°Roving Density(g/㎡) | Chop Density | Polyester Yarn Density(g/㎡) |

E-QX320 | 320.97 | 1.91 | 155.9 | 1.91 | 155.9 | - | 5.35 |

E-QX450 | 460.15 | 1.91 | 225.49 | 1.91 | 225.49 | - | 5.35 |

E-QX600 | 610.49 | 1.91 | 300.66 | 1.91 | 300.66 | - | 5.35 |

E-QX800 | 810.93 | 1.91 | 400.88 | 1.91 | 400.88 | - | 5.35 |

E-QX1000 | 1018.96 | 1.91 | 491.37 | 27.56 | 491.37 | - | 6.75 |

E-QX1150 | 1145.61 | 287.4 | 284 | 283.46 | 284 | - | 6.75 |

E-QX1200 | 1217.7 | 602.36 | 300.66 | 4.02 | 300.66 | - | 10 |

E-QXM620/98 | 722.33 | 15.75 | 300.66 | 1.91 | 300.66 | 98 | 5.35 |

E-QXM1300/128 | 1422.52 | 574.8 | 212.13 | 283.46 | 212.13 | 128 | 12 |

E-QXM1850/225 | 2104.06 | 472.44 | 467.69 | 462.99 | 467.69 | 225 | 8.25 |

FAQ

a.Pacage

Each Eglass stitched Combo Mat is wound onto a paper tube The roll is wrapped up with plastic film,and then packed in a cardboard box. The rolls can be vertically or horizontally placed. For transportation, the rolls can be loaded into a container directly or on pallets.

b.Product storage:

Unless otherwise specified, CHEMICAL FIBER GRIDDING CLOTH should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 50%~75% respectively.

- Q: Can fiberglass fabric be used for making protective covers?

- Yes, fiberglass fabric can be used for making protective covers.

- Q: Can fiberglass fabric be used for making shoes?

- Indeed, shoes can be crafted using fiberglass fabric. Fiberglass, a resilient and lightweight substance, finds extensive application in diverse sectors like automotive, aerospace, and construction. In the realm of footwear, fiberglass fabric imparts fortitude and steadiness while preserving the shoe's lightweight nature. This fabric can reinforce specific regions necessitating additional reinforcement, such as the toe cap or the heel counter, thereby amplifying the shoes' overall durability and structural soundness. Furthermore, fiberglass fabric boasts remarkable resistance to heat and chemicals, rendering it a prime selection for shoes subjected to rigorous environments.

- Q: Can fiberglass fabric be used for making backpacks or luggage?

- Fiberglass fabric is indeed suitable for manufacturing backpacks and luggage due to its strength and durability. This fabric is renowned for its ability to create sturdy and long-lasting bags. Moreover, it is lightweight, tear-resistant, and can withstand heavy loads. The fact that fiberglass fabric is widely used in industries like aerospace and automotive further emphasizes its suitability for backpacks and luggage. Nevertheless, it is important to consider that fiberglass fabric may not be as flexible or moldable as other materials, making it better suited for rigid or structured bag designs rather than soft or collapsible styles.

- Q: Are fiberglass fabrics suitable for use in the energy sector?

- Yes, fiberglass fabrics are suitable for use in the energy sector. They offer excellent thermal insulation properties, are resistant to high temperatures, and have high strength and durability. Fiberglass fabrics are commonly used in insulation systems, electrical insulation, and as a reinforcement material in composite structures, making them well-suited for various applications in the energy sector.

- Q: The pipe is too hot. What's the protection?

- Such products can be processed, composite aluminum foil, glass fiber cloth, so that its use more widely.

- Q: What is the typical tensile strength of fiberglass fabrics?

- The typical tensile strength of fiberglass fabrics can vary, but it is generally around 300-600 MPa (megapascals).

- Q: What does 240 grams of fiberglass cloth mean?

- Fiberglass cloth is also commonly called fiberglass geotextile. A geosynthetic material widely used in civil engineering. It is mainly made of glass fiber and staple fiber, needle punched non-woven fabric composite geosynthetics.

- Q: How does fiberglass fabric perform in water repellency?

- Fiberglass fabric exhibits exceptional water repellency due to its composition of woven glass fibers, which possess a natural hydrophobic quality. This inherent characteristic prevents water molecules from easily permeating the fabric, resulting in a high level of resistance to water absorption. The hydrophobic nature of fiberglass fabric makes it an ideal choice for applications where water repellency is essential, such as the manufacturing of outdoor apparel, tents, and boat covers. Even when exposed to water, the fabric remains relatively dry, avoiding any increase in weight or water saturation. Furthermore, the construction of fiberglass fabric enables it to maintain its water repellency over an extended period. The fabric does not readily lose its hydrophobic properties, even with repeated exposure to water or washing. This durability makes fiberglass fabric a reliable option for situations requiring long-term water resistance. It is worth noting, however, that while fiberglass fabric exhibits a high resistance to water absorption, it is not entirely waterproof. Under extreme circumstances like heavy rainfall or prolonged submersion, some water may eventually seep through the fabric. Nevertheless, fiberglass fabric surpasses many other materials in terms of water repellency, making it a favored choice across various industries.

- Q: Can fiberglass fabric be used in chemical-resistant applications?

- Yes, fiberglass fabric can be used in chemical-resistant applications. It is known for its excellent resistance to a wide range of chemicals and is often used in industries such as chemical processing, oil and gas, and wastewater treatment.

- Q: Is fiberglass fabric resistant to fire?

- Yes, fiberglass fabric is resistant to fire. Fiberglass is made from fine fibers of glass that are woven into a fabric. The glass fibers have a high melting point, which means they do not easily catch fire or burn. Additionally, fiberglass fabric is often treated with fire-resistant coatings or chemicals to enhance its fire resistance properties. This makes it an excellent choice for applications where fire resistance is required, such as protective clothing, insulation materials, and fireproof curtains. However, it is important to note that while fiberglass fabric is resistant to fire, it is not completely fireproof and can still melt or degrade under extreme heat conditions.

Send your message to us

E-GLASS STITCH COMBO MAT- QX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords