All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

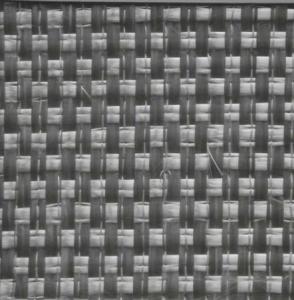

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Fiberglass Chopped StrandView More

Fiberglass Mesh ClothView More

Composite PipesView More

FRP Pultrusion ProfilesView More

Fiberglass Mat TissueView More

Fiberglass FabricsView More

Fiberglass MeshView More

Composite TankView More

Fiberglass Mesh tapeView More

PolymerView More

FRP Roofing PanelView More

Fiberglass RovingView More

Q & A

How do I repair fiberglass?

To repair fiberglass, start by cleaning the damaged area thoroughly and removing any loose fragments. Then, sand down the surface around the damaged area to create a smooth and clean surface for the repair. Next, apply a fiberglass repair kit, which typically includes resin and hardener, following the instructions provided. Use a brush or roller to apply multiple layers of the repair mixture, allowing each layer to dry before applying the next. Finally, sand the repaired area to blend it with the surrounding surface and finish off with a coat of paint or gel coat for a seamless finish.

How does fiberglass compare to carbon fiber?

Fiberglass and carbon fiber are both composite materials, but they have different properties and uses. Fiberglass is less expensive and more widely available, making it a popular choice for applications where cost is a significant factor. On the other hand, carbon fiber is stronger, stiffer, and lighter than fiberglass, making it ideal for high-performance and aerospace applications where weight reduction is crucial. Therefore, the choice between fiberglass and carbon fiber depends on the specific requirements and budget of the project.

How is fiberglass supply recycled?

Fiberglass supply is typically recycled through a process called mechanical recycling. This involves grinding or shredding the fiberglass material into smaller particles, which can then be used as a raw material for various applications. The recycled fiberglass can be incorporated into new products such as insulation, construction materials, or even automotive parts. Additionally, some recycling facilities also use chemical processes to break down the fiberglass into its constituent components for further reuse.

What are the different types of fiberglass fabrics and mats?

There are several different types of fiberglass fabrics and mats available, including woven fabrics, chopped strand mats, continuous strand mats, and surface veil mats. Woven fabrics are made by weaving together individual fiberglass strands, resulting in a strong and durable material. Chopped strand mats consist of randomly oriented strands that are held together with a binder. Continuous strand mats are similar to chopped strand mats but have strands that are more aligned. Surface veil mats are thin and lightweight fabrics that are used to improve the surface finish of fiberglass composites.

Is fiberglass resistant to corrosion?

Yes, fiberglass is highly resistant to corrosion.

Wholesale Fiberglass Supply from supplier in Afghanistan

Our team of experts is knowledgeable about the specific requirements and challenges of working in Afghanistan, and we can assist you in finding the right Fiberglass Supply products for your projects. Whether you need Fiberglass Reinforced Panels, Fiberglass Insulation, Fiberglass Grating, or any other Fiberglass Supply product, we have you covered.

We understand the importance of quality and reliability, which is why we only work with reputable manufacturers and suppliers. Our Fiberglass Supply products are made from high-quality materials and are built to withstand the harsh conditions of the Afghan climate. We ensure that all our products meet international standards and are certified for their performance and durability.

In addition to our wide range of products, we also offer competitive pricing and flexible payment options to meet your budget requirements. We strive to provide excellent customer service and timely delivery of your orders, ensuring that your projects stay on track.

Furthermore, our technical support team is available to assist you with any questions or concerns you may have about our Fiberglass Supply products. We can provide guidance on installation techniques, maintenance tips, and troubleshooting solutions, ensuring that you have the necessary support throughout your project.

At CNBM, we value long-term partnerships and aim to build strong relationships with our customers in Afghanistan. We are committed to meeting your Fiberglass Supply needs and exceeding your expectations. Contact us today to discuss your requirements and let us provide you with the best solutions for your projects in Afghanistan.

We understand the importance of quality and reliability, which is why we only work with reputable manufacturers and suppliers. Our Fiberglass Supply products are made from high-quality materials and are built to withstand the harsh conditions of the Afghan climate. We ensure that all our products meet international standards and are certified for their performance and durability.

In addition to our wide range of products, we also offer competitive pricing and flexible payment options to meet your budget requirements. We strive to provide excellent customer service and timely delivery of your orders, ensuring that your projects stay on track.

Furthermore, our technical support team is available to assist you with any questions or concerns you may have about our Fiberglass Supply products. We can provide guidance on installation techniques, maintenance tips, and troubleshooting solutions, ensuring that you have the necessary support throughout your project.

At CNBM, we value long-term partnerships and aim to build strong relationships with our customers in Afghanistan. We are committed to meeting your Fiberglass Supply needs and exceeding your expectations. Contact us today to discuss your requirements and let us provide you with the best solutions for your projects in Afghanistan.